Metal-free prefabricated cement sheet composite wall

A metal-free, combined wall technology, applied in the direction of walls, buildings, building types, etc., can solve the problems of poor integrity of rammed earth formwork, unload-bearing walls, inconvenient transportation, etc. Bearing capacity, ease of transportation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

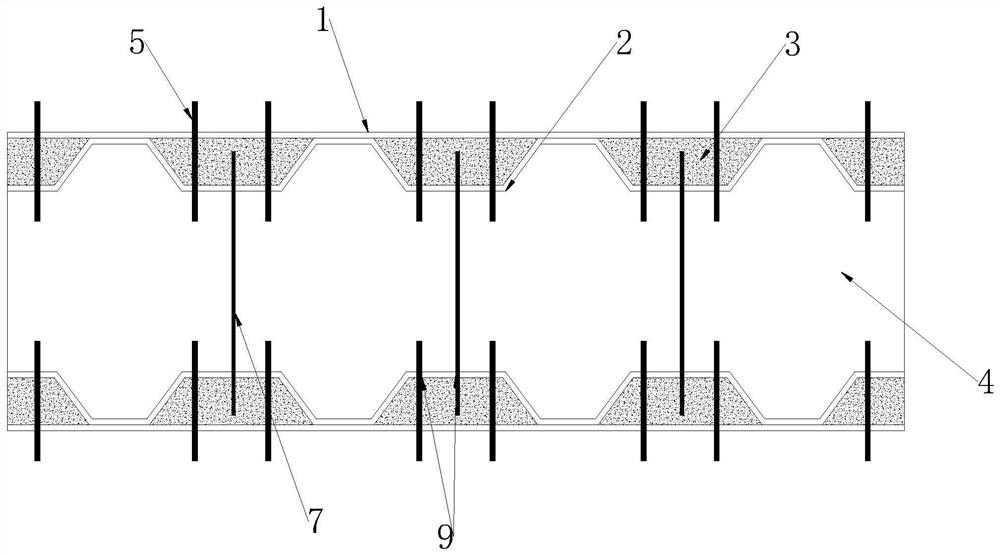

[0032] Example: such as figure 1 As shown, a metal-free prefabricated cement sheet composite wall includes two parallel formworks, both formworks are made of prefabricated fabric reinforced concrete sheets, and the opposite surfaces of the two parallel formworks are provided with a plurality of trapezoidal columns arranged along the wall surface 3 , connect the two parallel formworks through connectors to form a wall formwork, and fill in a filler 4 between the two parallel formworks to form a wall. The filler 4 includes raw soil, composite soil, cement soil and cement sand and gravel.

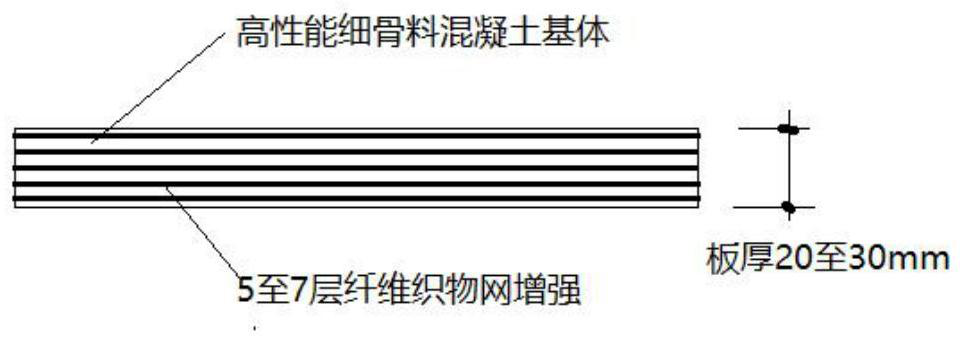

[0033] refer to figure 2 As shown, in this embodiment, the method of laying layers is adopted in the thin plate, that is, it is made by layer-by-layer laying of fiber fabric nets, and it is made by referring to figure 2 As shown, lay 5-7 layers of fiber fabric mesh in a thickness of 2 to 3 cm.

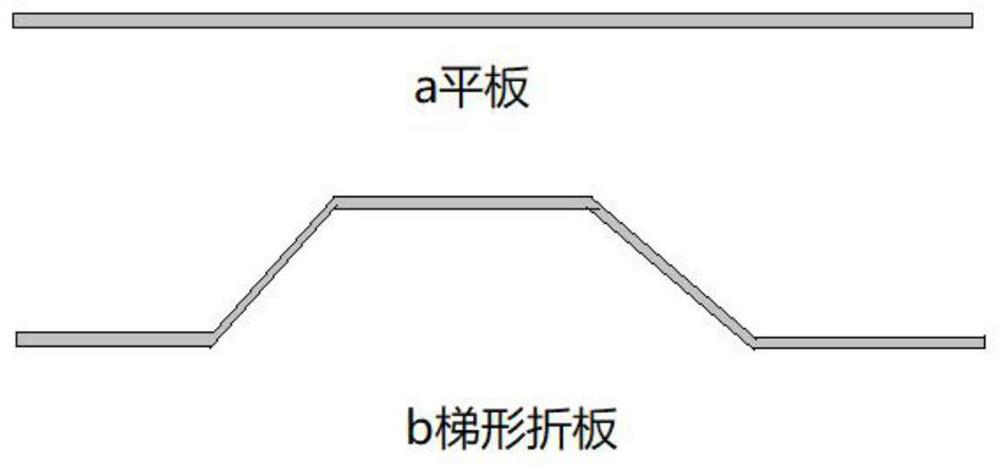

[0034] Among them, each formwork includes a flat plate 1 and a trapezoidal folded plate 2. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com