Secondary fractal spiral electrostatic spinning head and tertiary fractal spiral electrostatic spinning head

A technology of electrospinning and spiral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

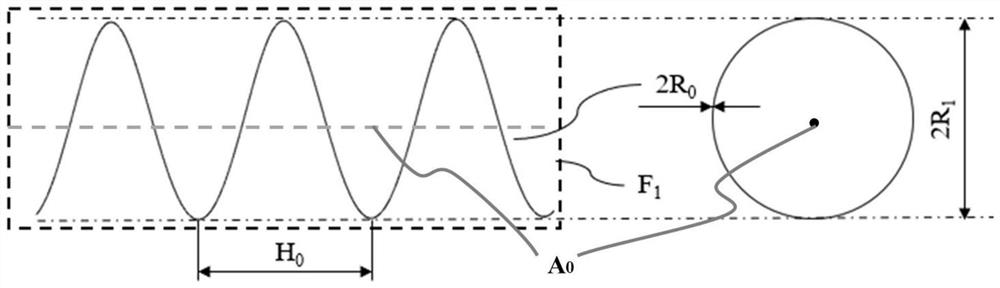

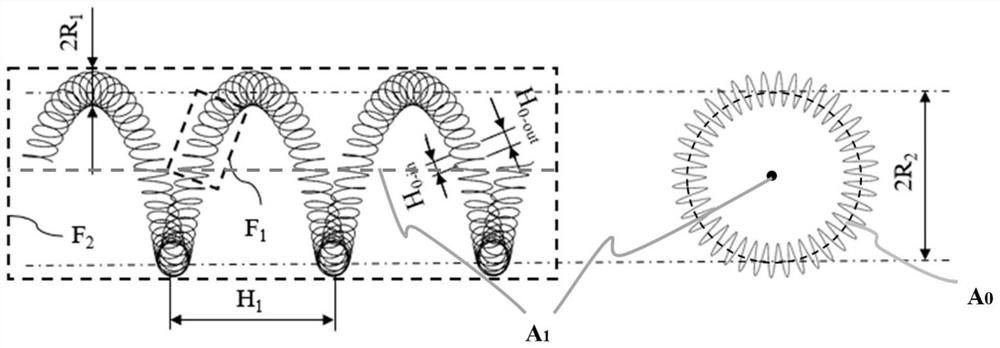

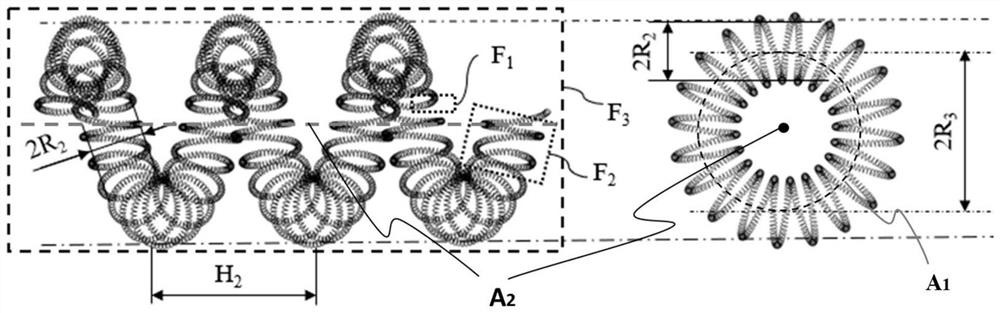

[0044] Such as figure 2 As shown, this embodiment provides a secondary fractal spiral electrospinning head, a secondary fractal spiral structure formed by a primary spiral electrospinning head based on a helical coil, and its material is spring steel.

[0045] where the quadratic fractal spiral radius R 2 10mm, primary spiral radius R 1 is 2mm, and the number of coils of the quadratic fractal spiral is M 1 is 40 turns, the pitch H of the quadratic fractal spiral 1 20mm, wire R 0 The radius is 0.1 mm.

Embodiment 2

[0047] With embodiment 1, its difference is: quadratic fractal spiral radius R 2 40mm, primary spiral radius R 1 is 5mm, and the number of coils of the quadratic fractal spiral is M 1 is 50 turns, the pitch H of the quadratic fractal spiral 1 50mm, wire R 0 The radius is 0.25mm.

Embodiment 3

[0049] With embodiment 1, its difference is: quadratic fractal spiral radius R 2 250mm, primary spiral radius R 1 is 20mm, and the number of coils of the quadratic fractal spiral is M 1 is 60 turns, the pitch H of the quadratic fractal spiral 1 120mm, wire R 0 The radius is 1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com