Mineral source biochar soil conditioner and preparation method thereof

A soil conditioner and bio-source technology, applied in the preparation of the soil conditioner, in the field of mineral-sourced biochar soil conditioner, can solve the problems of insufficient nutrients and single conditioning effect, and achieve the promotion of soil microbial activity, sufficient and easy-to-obtain raw materials, The effect of promoting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

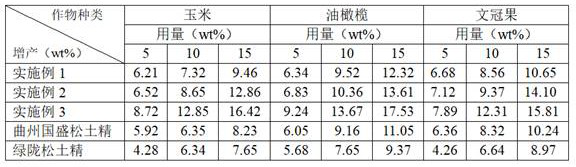

Examples

Embodiment 1

[0032]In this example, the content of organic matter in mineral biochar is 250.0g / kg, organic carbon is 120.0g / kg, total nitrogen is 3.5g / kg, total phosphorus is 0.5g / kg, total potassium is 10.0g / kg, Ca 0.6 g / kg, Mg0. 6 g / kg, pH 8.3. In the composite microbial agent, the effective viable count of Bacillus subtilis is 150 million cfu / g, the effective viable count of Bacillus megaterium phosphate solubilizer is 0.1 billion cfu / g, and the effective viable count of Bacillus coliformis is 0.1 billion cfu / g, the effective viable count of streptomyces is 30 million cfu / g, the effective viable count of acetic acid bacteria is 0.1 billion cfu / g, and the effective viable count of lactic acid bacteria is 0.2 billion cfu / g.

[0033] Activation of mineral-sourced biochar: Soak mineral-sourced biochar in 0.5mol / L potassium hydroxide, activate for 5 hours, wash 3 times with hot water at 82°C and distilled water at room temperature, and then soak the activated mineral-sourced biochar with 2....

Embodiment 2

[0038] In this example, the content of organic matter in mineral biochar is 260.0g / kg, organic carbon is 130.0g / kg, total nitrogen is 4.0g / kg, total phosphorus is 0.6g / kg, total potassium is 12.0g / kg, Ca 0.7 g / kg, Mg0. 7 g / kg, pH 8.3. In the composite microbial agent, the effective viable count of Bacillus subtilis is 200 million cfu / g, the effective viable count of Bacillus megaterium phosphate solubilizer is 30 million cfu / g, and the effective viable count of Bacillus colloidus is 30 million cfu / g, the effective viable count of streptomyces is 0.4 billion cfu / g, the effective viable count of acetic acid bacteria is 0.1 billion cfu / g, and the effective viable count of lactic acid bacteria is 0.3 billion cfu / g.

[0039] Activation of mineral-sourced biochar: Soak mineral-sourced biochar in 1.0mol / L potassium hydroxide, activate for 3 hours, wash 3 times with hot water at 80°C and distilled water at room temperature, and then soak the activated mineral-sourced biochar with 4.0...

Embodiment 3

[0044] In this example, the content of organic matter in mineral biochar is 270.0g / kg, organic carbon is 150.0g / kg, total nitrogen is 4.5g / kg, total phosphorus is 0.7g / kg, total potassium is 13.0g / kg, Ca 0.8 g / kg, Mg 0.8 g / kg, pH8.3. In the composite microbial agent, the effective viable count of Bacillus subtilis is 250 million cfu / g, the effective viable count of Bacillus megaterium phosphate solubilizer is 0.6 billion cfu / g, and the effective viable count of Bacillus coliformis is 50 million cfu / g, the effective viable count of streptomyces is 0.6 billion cfu / g, the effective viable count of acetic acid bacteria is 0.2 billion cfu / g, and the effective viable count of lactic acid bacteria is 0.5 billion cfu / g.

[0045] Activation of mineral-sourced biochar: Soak mineral-sourced biochar in 2.0mol / L potassium hydroxide, activate for 5 hours, wash 3 times with hot water at 80°C and distilled water at room temperature, and then soak the activated mineral-sourced biochar with 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com