Steel bar dephosphorization machine

A technology of a steel dephosphorization machine and a box, which is applied to the parts of grinding machine tools, grinders, grinding/polishing equipment, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

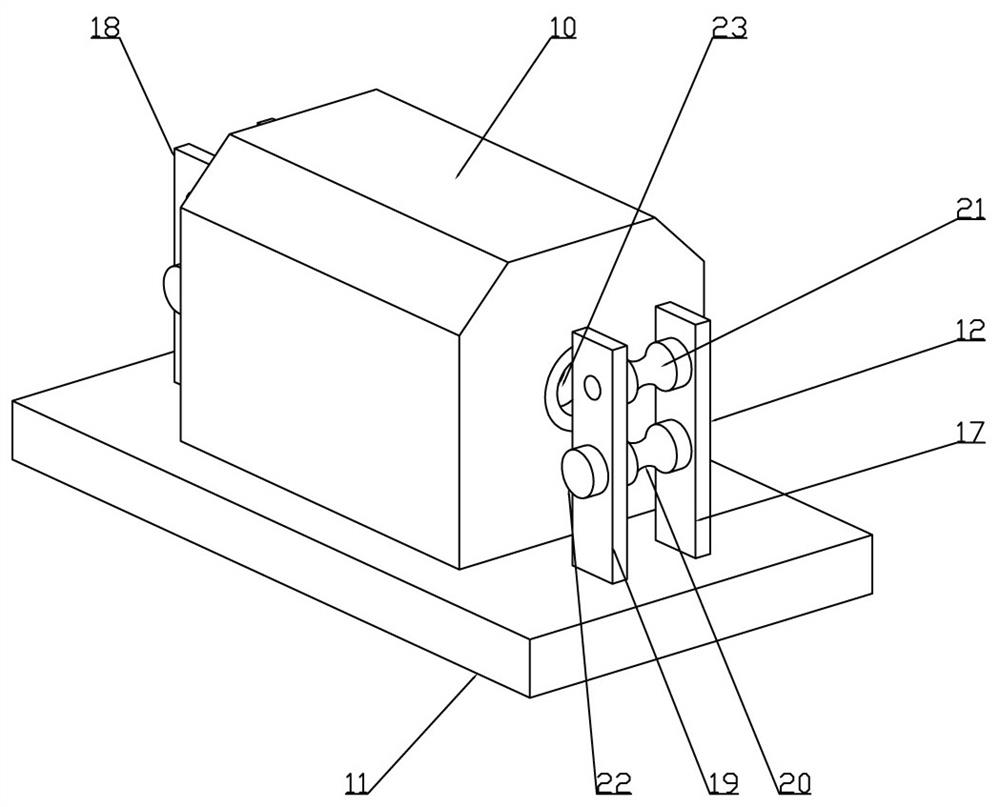

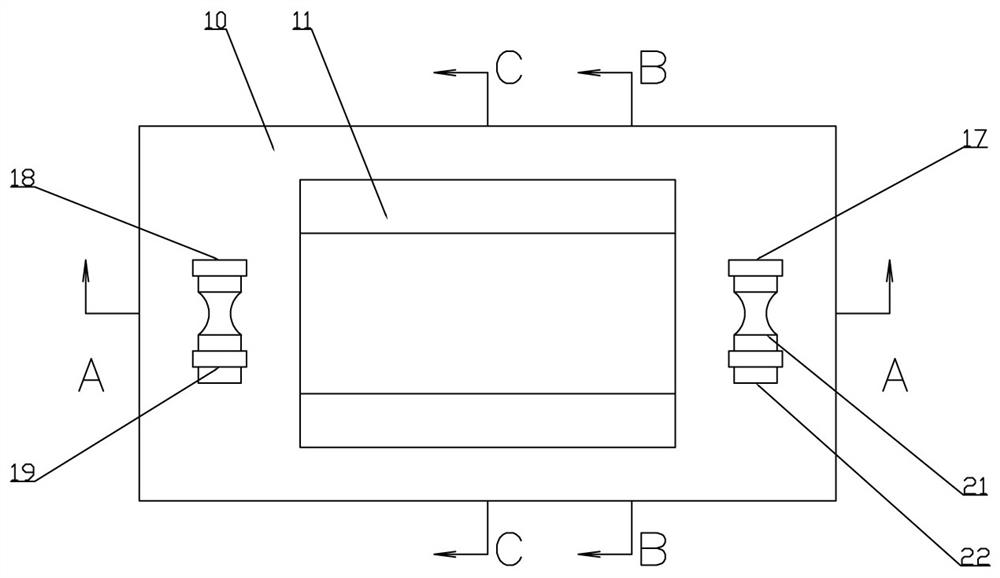

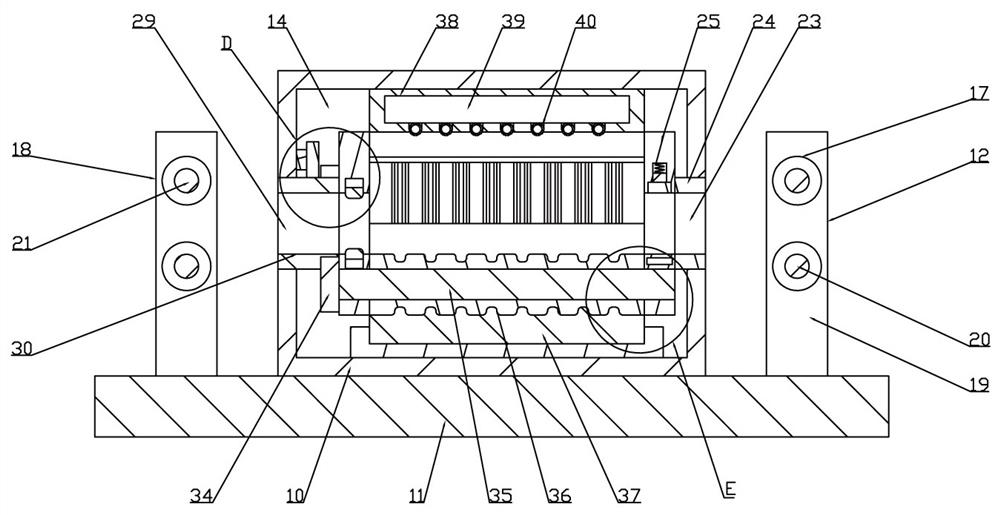

[0026] to combine Figure 1-8 , a steel dephosphorization machine, comprising a box 10, one end of the box 10 is provided with an inlet 23, the inside of the box 10 is provided with an outlet 29 away from the direction of the inlet 23, and the inside of the box 10 is rotated on the periphery of the inlet 23. A first rotating ring 24 is arranged, and the first rotating ring 24 is fixedly provided with a first rotating disk 25 toward the inside of the casing 10, and the inside of the casing 10 rotates on the periphery of the outlet 29 to be provided with a second rotating ring 30, and the second rotating ring 30 is fixedly provided with the second rotating disk 31 toward the inner direction of box body 10, and is connected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com