Three-Y-axis mirror image turn-milling center lathe bed and functional parts thereof

A Y-axis and bed technology, which is applied in the field of ultra-precision multi-function cutting machine tools, bed and related functional parts, can solve the problems of deformation, the inability to discharge the chip pool, and the waste of idle resources. , to achieve the effect of improving efficiency, increasing stress deformation coefficient, and meeting the needs of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the implementation technical solution will be clearly and completely described in examples, but this is only an embodiment of the present invention, not all embodiments. Based on the technical principles and structural features of the present invention, other similar embodiments that can be obtained by those skilled in the art without making breakthrough creative efforts, all of which belong to the protection scope of the present invention.

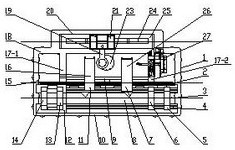

[0042] Manufacture a rectangular main bed (1) with mineral casting technology, the size is determined by the type and stroke of the turning and milling spindle. The dimensions of the bed (1) are set at 5 meters in length, 2.9 meters in width, and 0.5 meters in height. Evacuate, the center position is the inverted triangular centroid pool (storage pool) (8, 81), and the two ends of the Y axis of the inverted triangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com