Pebble coal collecting device and pebble coal collecting method

A collection device, a technology of pebble coal, applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of unstable air pressure, low operation efficiency, inability to maintain stable air pressure, etc., to achieve stable air pressure, easy to move and Fixed and guaranteed the effect of continuous collection and processing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

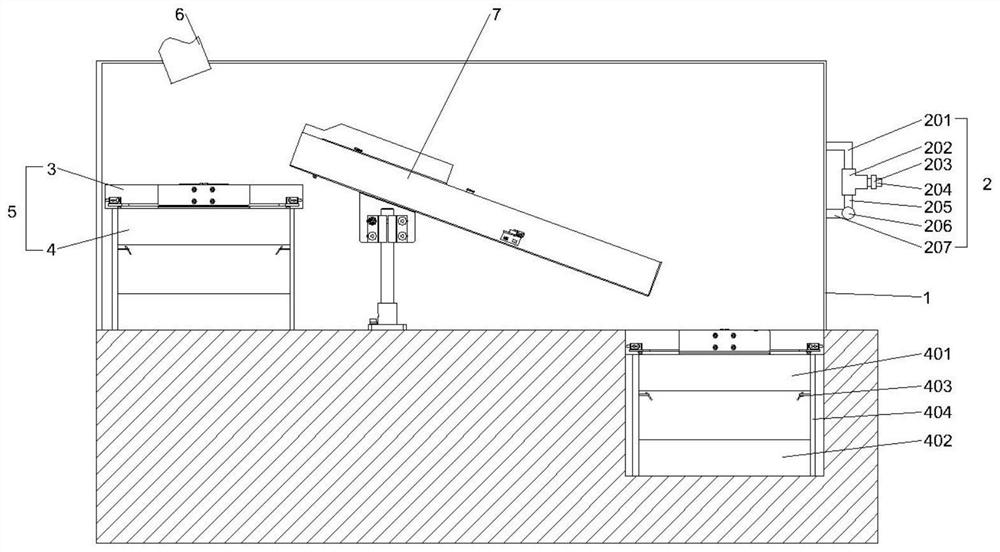

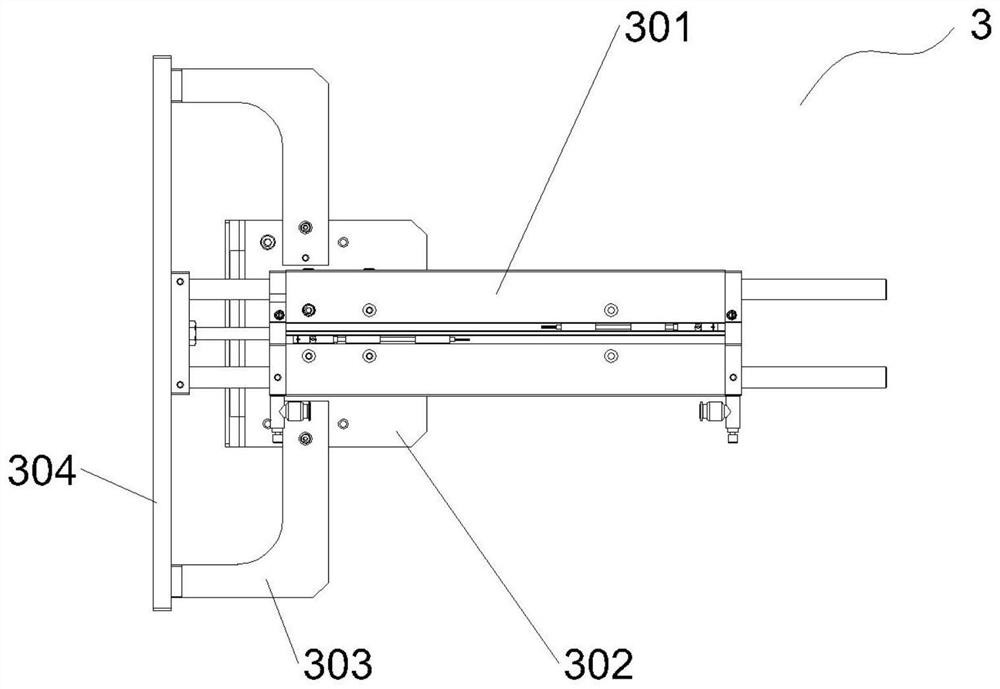

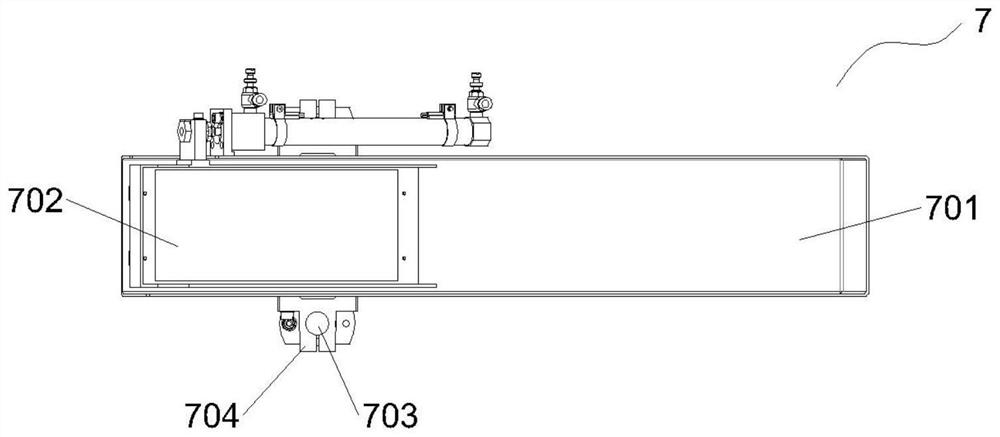

[0034] Such as figure 1 As shown, the present invention provides a collection device for pebble coal, including a discharge port 6, a collection and transportation device 5 located directly below the discharge port 6, and a packing mechanism 7 placed on one side of the collection and transportation device 5 , used for subpackaging the pebble coal discharged from the discharge port 6, reducing the transportation burden of the collection and transportation device 5, while ensuring the continuous collection and processing of the pebble coal; the collection and transportation device located directly below the other side of the subpackaging mechanism 5. The dust cover 1 covering the collecting and transporting device 5 and the packaging mechanism 7, the discharge port 6 passes through the dust cover 1, and the air pressure regulating device 2 is installed on the dust cover 1 , used to adjust the air pressure inside the device to ensure the stability of the air pressure inside the d...

Embodiment 2

[0053] like Figure 5 As shown, the collection device for pebble coal also includes a roller 8 installed on the bottom surface of the mounting seat assembly, and handles 9 installed on both sides of the synchronous belt assembly three 701, so that the sub-packaging mechanism 7 is easy to move, and the roller 8 is horizontal Adjust caster, be convenient to packing mechanism 7 and fix, other devices and installation position are all the same.

[0054] The collection method of embodiment two is the same as the collection method of embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com