Flour mill with water cooling structure on movable millstone

A technology of milling machine and moving grinding disc, which is applied in cocoa, grain processing, food science, etc. It can solve the problems of unable to meet the cooling demand, affect the grinding effect, reduce the production speed and service life, etc., so as to improve production efficiency and production quality , improve heat exchange efficiency, and meet the effect of water cooling and cooling requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention;

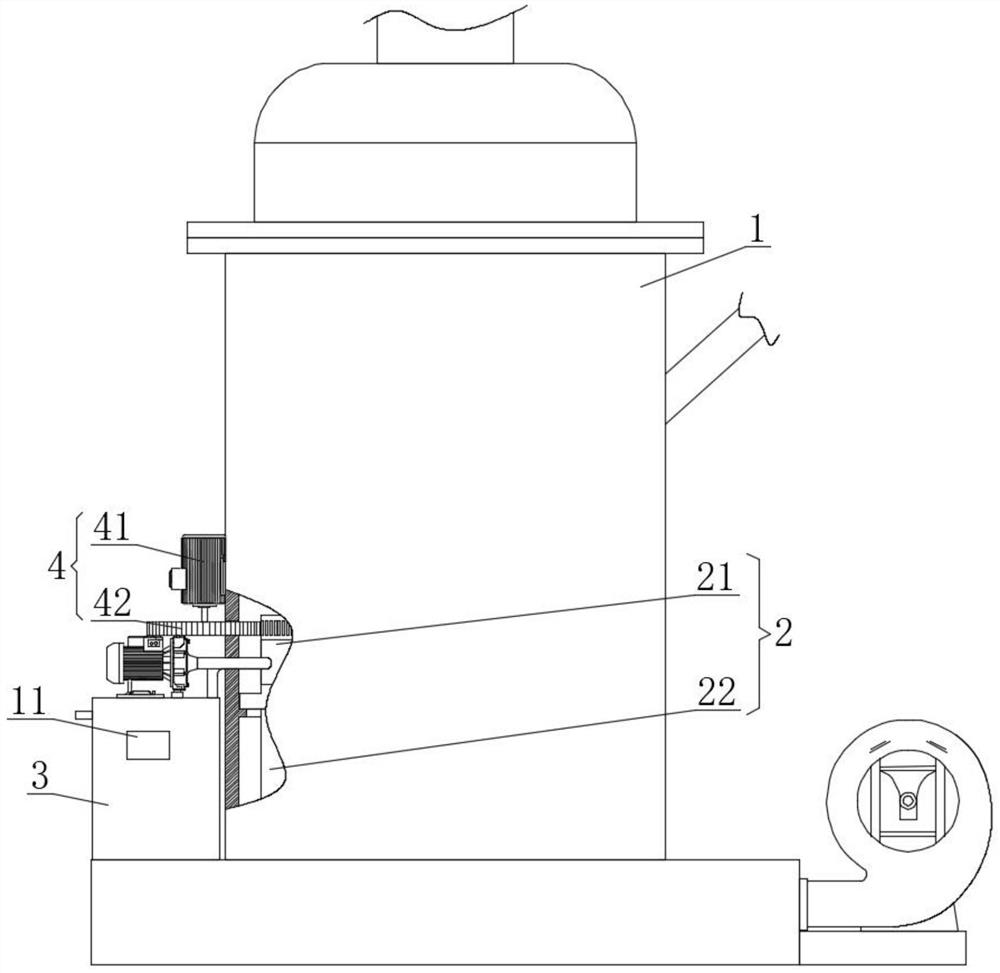

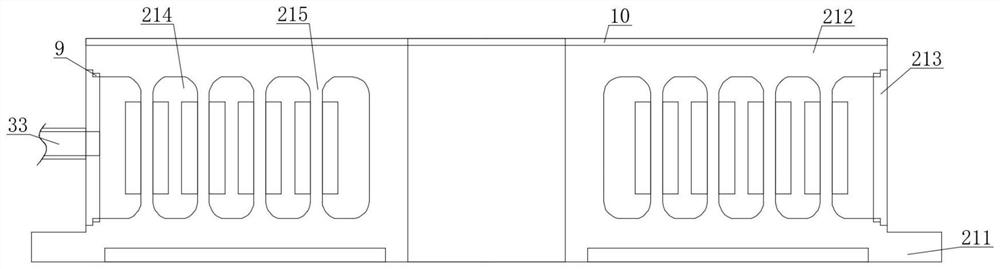

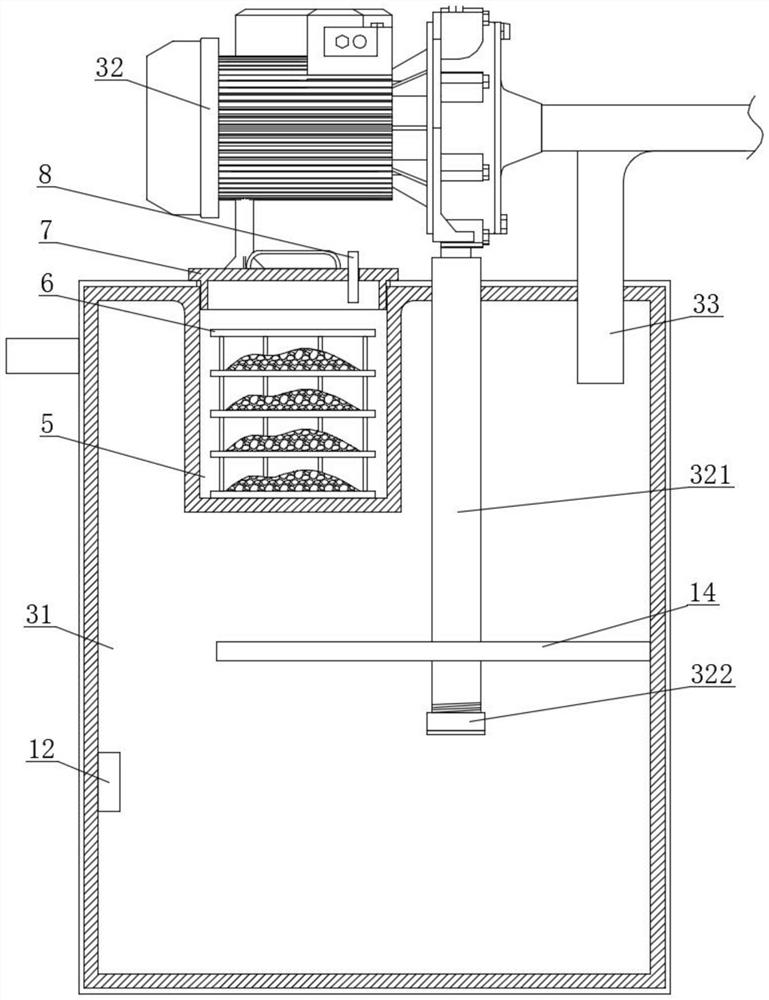

[0034] see Figure 1~4 , in the present invention, a mill with a water-cooled structure on a movable milling table includes a mill main body 1, a milling component 2 is installed on the inner side of the mill main body 1, and a The water-cooling mechanism 3 and the transmission mechanism 4, the right side of the water-cooling mechanism 3 runs through the main body 1 of the mill and is connected with the milling part 2. The milling part 2 includes a movable millstone 21 and a fixed millstone 22, and the movable millstone 21 is rotatably connected to the mill Inside the machine main body 1, the fixed grinding disc 22 is fixedly installed inside the mill main body 1;

[0035] The moving grinding table 21 includes a grinding plate 211. The top of the grinding plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com