Efficient water ring granulator with automatic tangent plane attaching function and using method of efficient water ring granulator

A granulator and bonding technology, which is applied in metal processing and other directions, can solve the problems of affecting the quality of finished products, difficult operation, uneven particle incision, etc., and achieve the effect of improving compatibility, safety and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

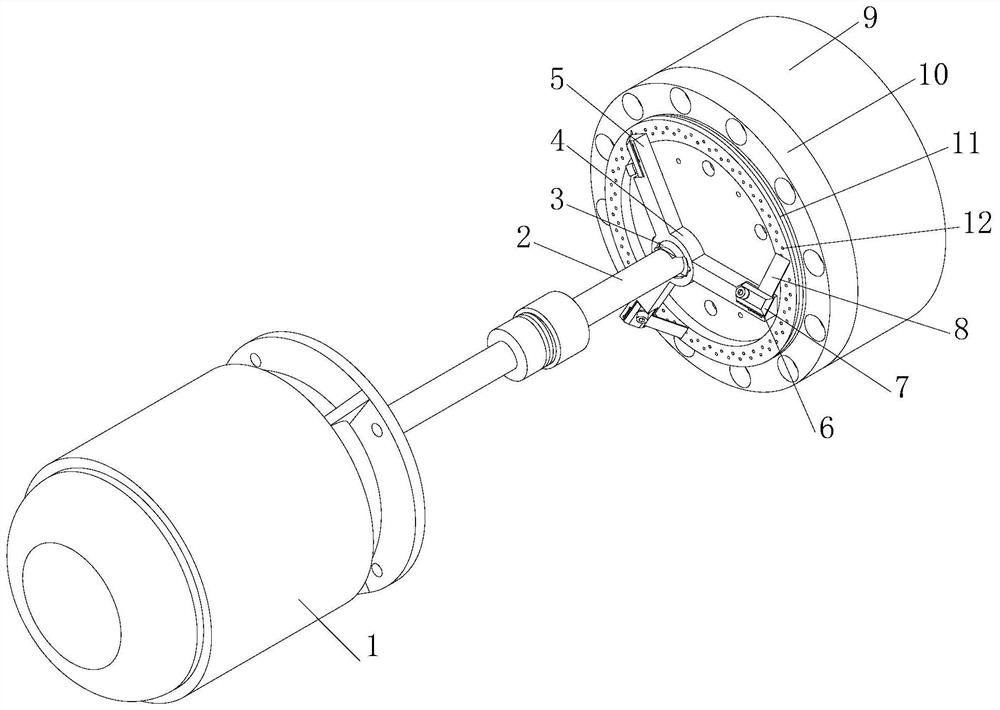

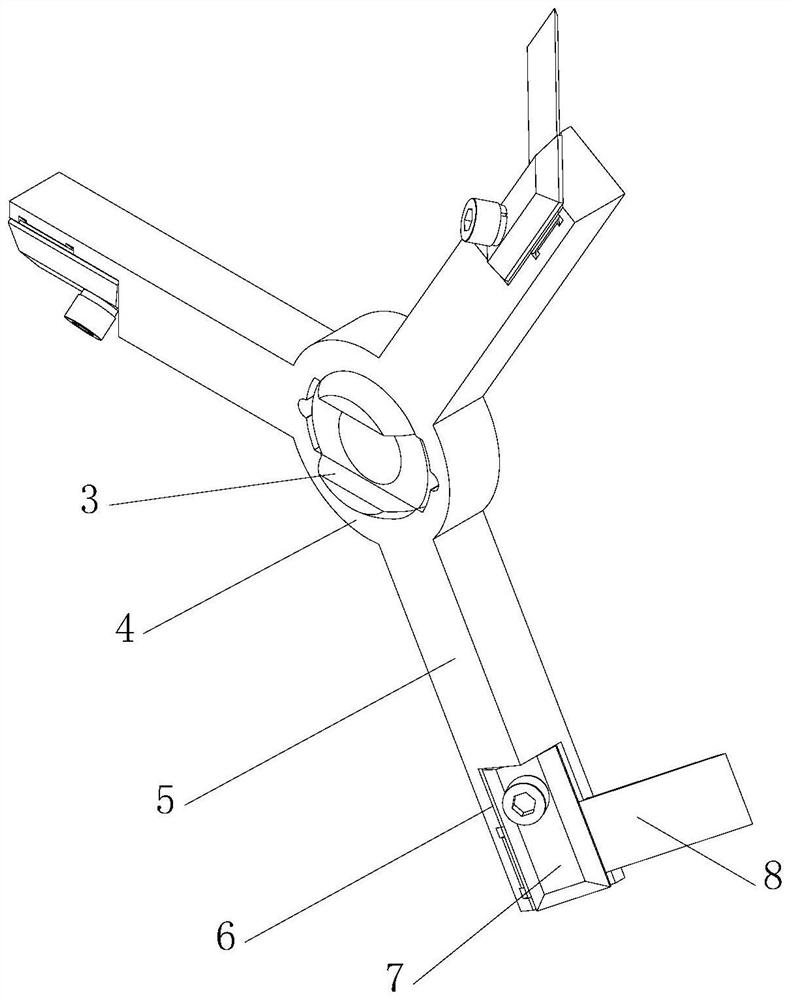

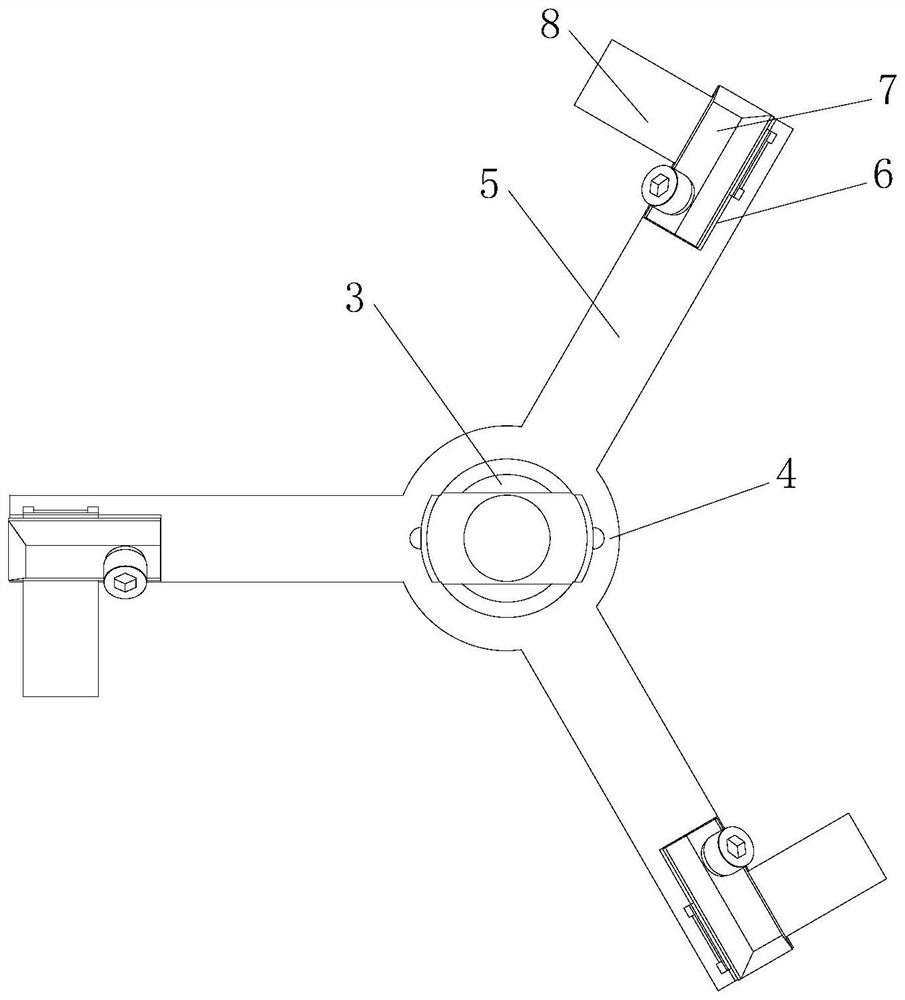

[0036] Such as Figure 1-Figure 6 As shown in the present invention, a cut-surface automatic laminating high-efficiency water ring pelletizer includes an extruder end 9 for extruding raw materials, a motor 1, and a motor 1 output end connected by a connecting assembly. The driven shaft 2, the other end of the driven shaft 2 is sleeved with a spherical bearing 3, the outside of the spherical bearing 3 is sleeved with a rotatable cutter head holder 4, and the outer edge of the cutter head holder 4 is evenly extended with a plurality of extensions. Arm 5, a cutter 8 is installed on the extension arm 5, three extension arms 5 are installed on the side surface of the cutter head holder 4 in the present embodiment, and a cutter 8 is installed on each extension arm 5;

[0037] The end of the extruder head 9 is fixedly provided with a sealing cover 10, and the end of the sealing cover 10 away from the extruder head 9 is provided with an extended convex ring 11, and the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com