Electric vehicle permanent magnet motor with stator and rotor integrated ventilation cooling structure

A ventilation cooling and electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve the problem of safe and reliable operation of irreversible demagnetization of permanent magnets at the end of the motor, poor cooling effect of the end of the motor and permanent magnets, and harsh heat dissipation environment, etc. problem, to avoid the problem of thermal demagnetization, good cooling effect, and improve the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

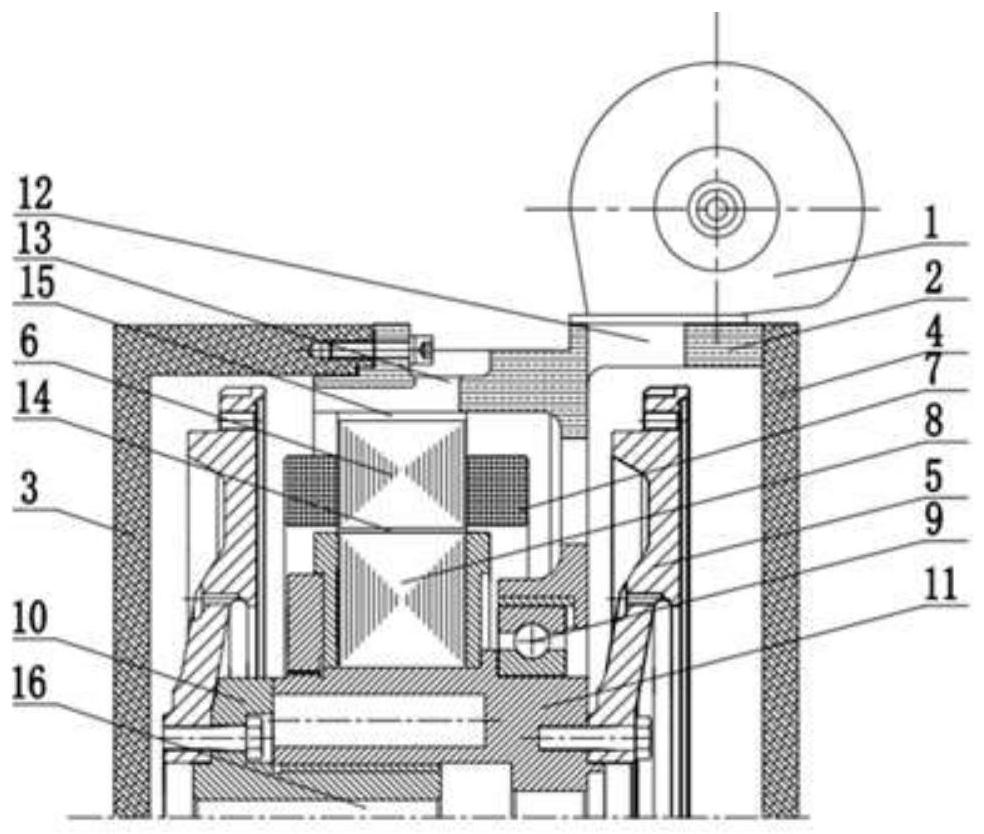

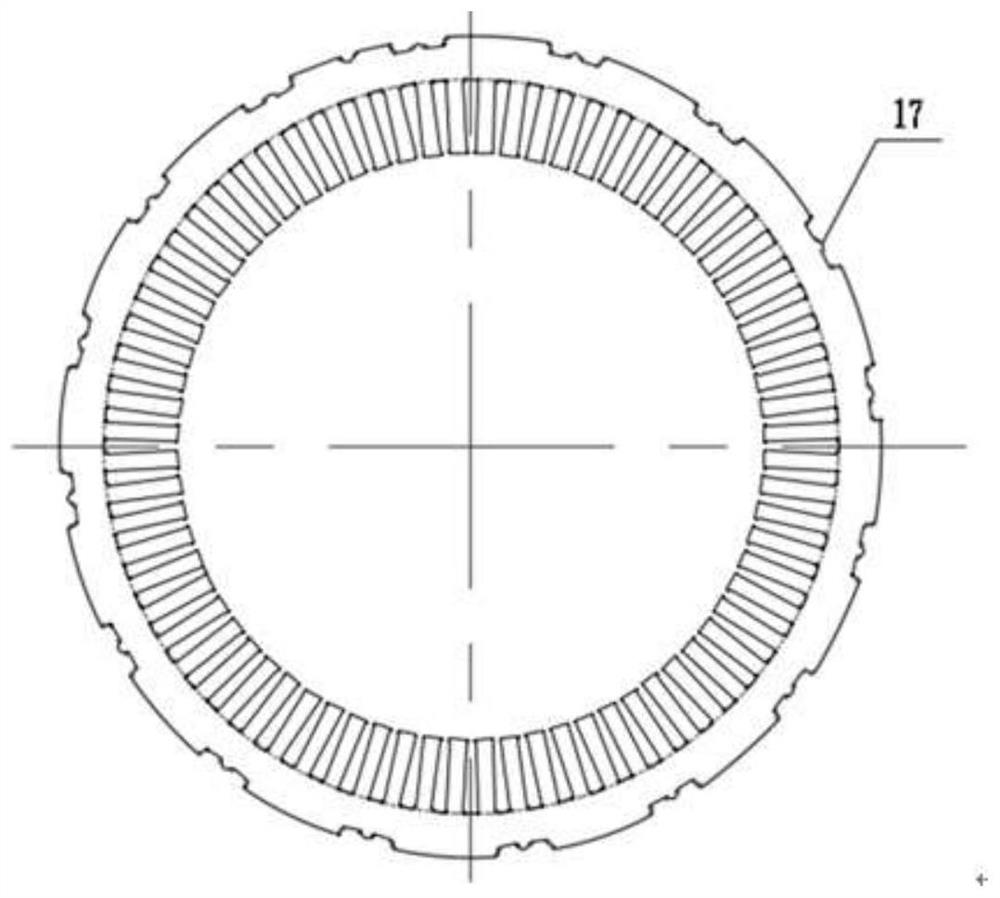

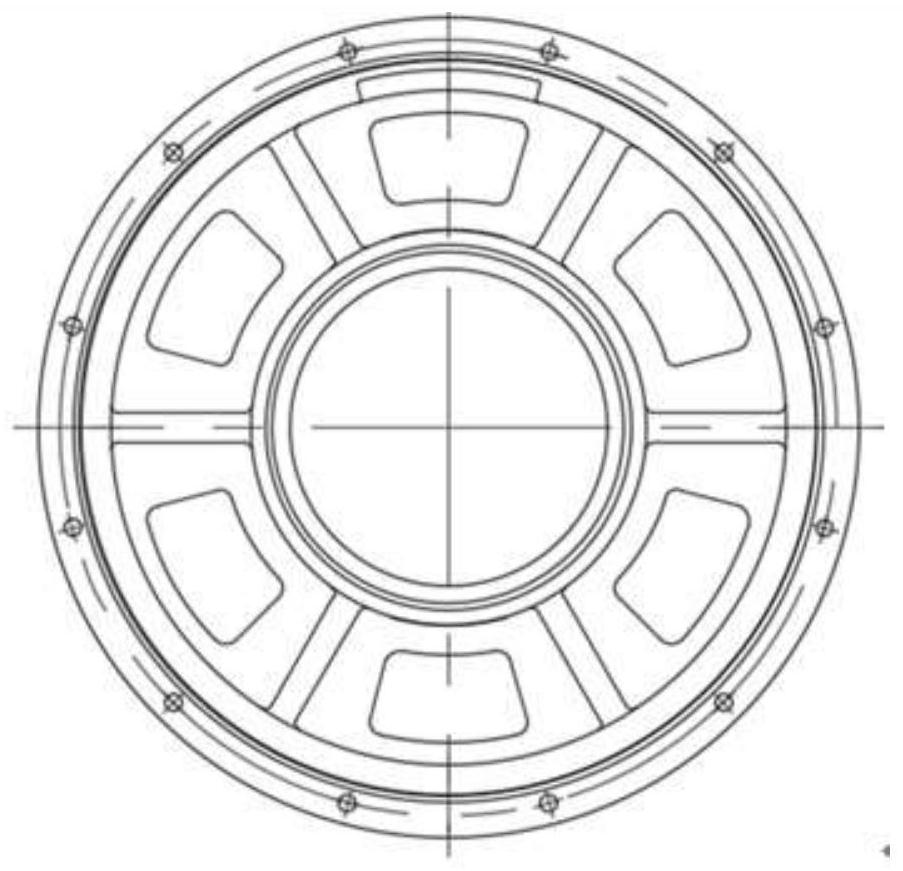

[0012] Such as figure 1 As shown, the present invention includes blower 1, casing 2, left end cover 3, right end cover 4, flywheel 5, stator core 6, winding 7, rotor 8, bearing 9, rotating shaft left end 10, rotating shaft right end 11, air inlet 12, outlet Tuyere 13 forms. The blower 1 is fixed at the air inlet 12 of the casing 2. A stator core 6 is arranged inside the casing 2, and a winding 7 is embedded inside the stator core 6. The casing 2 is connected to the right end 11 of the rotating shaft through a bearing 9, and the right end of the rotating shaft is covered with a The rotor 8 and the permanent magnet are assembled inside the rotor. The left end 10 of the rotating shaft and the right end 11 of the rotating shaft are connected by splines, and are connected with the flywheel 5 respectively. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com