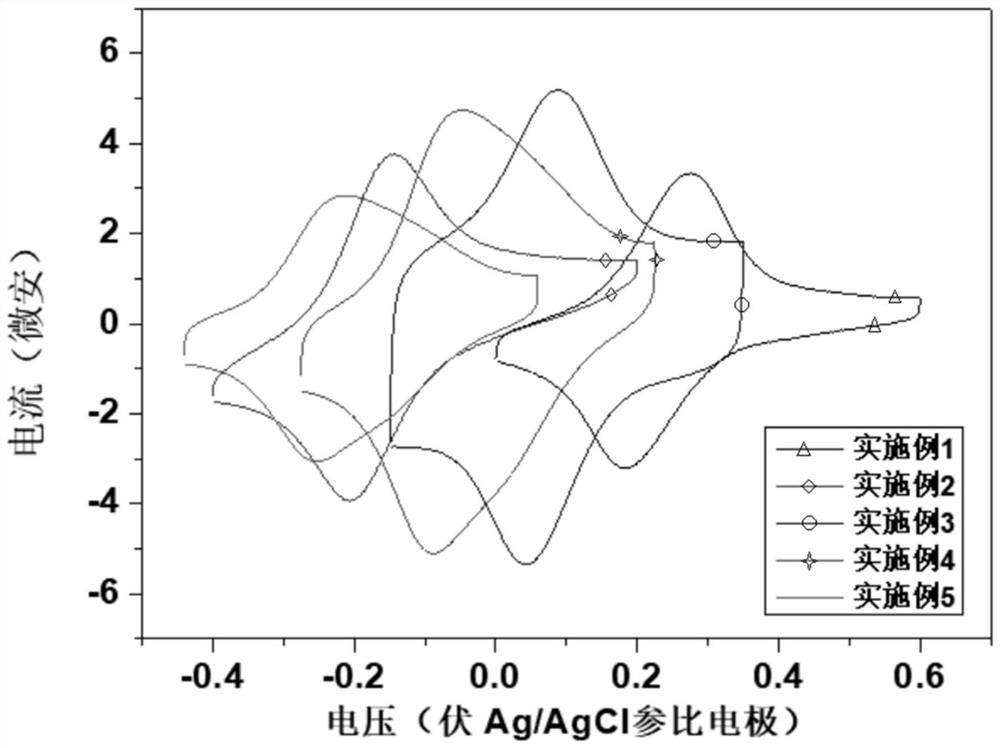

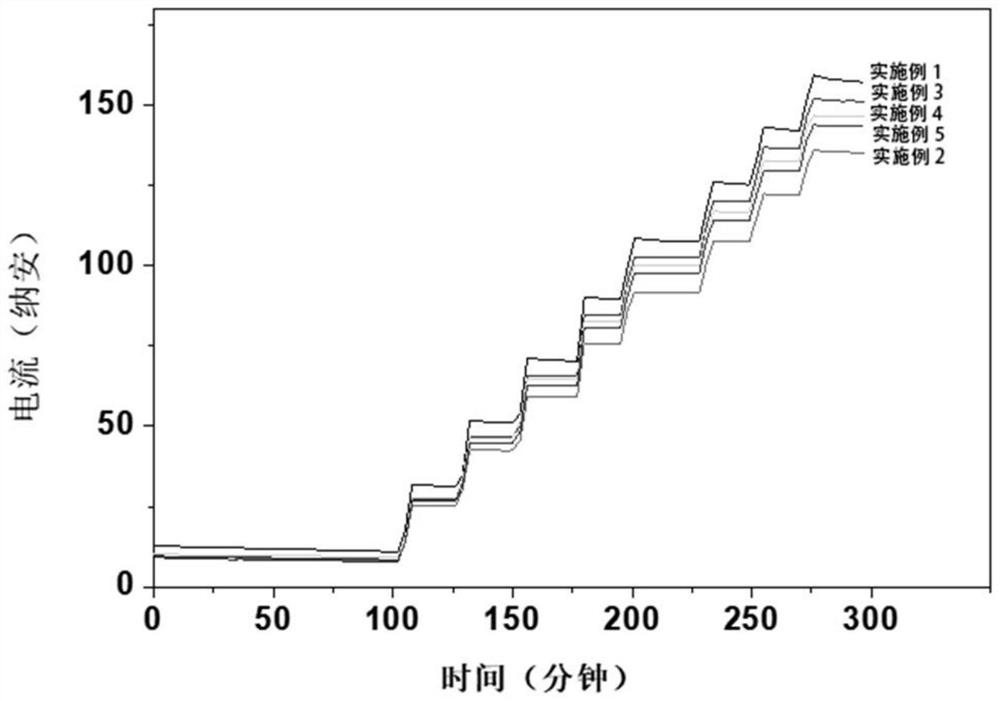

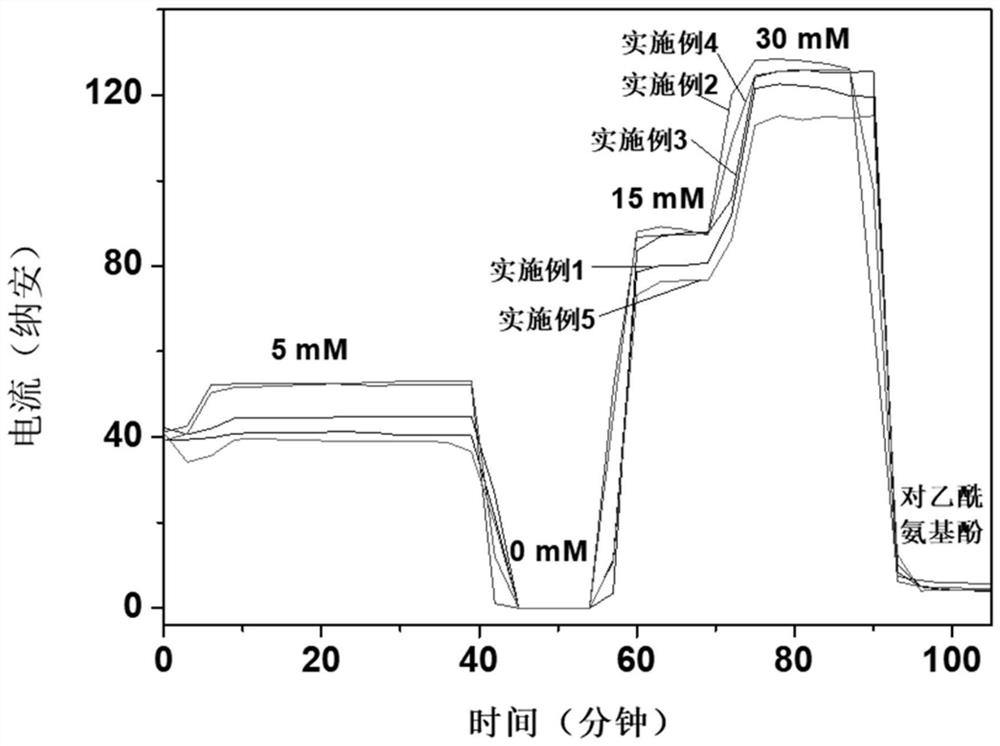

Conductive nano-material glucose sensing material as well as preparation method and application thereof

A technology of conductive nano and sensing materials, which is applied in the direction of material analysis, analysis materials, instruments, etc. by electromagnetic means, can solve the problems of reduced sensitivity and weakened anti-interference ability, and increase the rate of transferred electrons and linear correlation coefficient High, the effect of overcoming the oxygen effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a redox ligand-based conductive nanomaterial glucose sensing material, the preparation process of which includes the following steps:

[0033] A. Weigh 1-100mg of multi-walled carbon nanotubes into a 10mL vial, add 1-3mL of deionized water and 0.01-1mL of 3-aminopropyltriethoxysilane, and sonicate for 10-100min to obtain a uniform dispersion solution, placed at 25-50°C for 1-24 hours, 0.1-100 μL of 0.1M hydrochloric acid was added to it, placed at room temperature for 6-48 hours, the obtained suspension was dialyzed, and the dialyzed suspension was washed by centrifugation several times to obtain carbon with amino groups on the surface. nanotube.

[0034] B. Mix 10~100mg Os(bpy) 2 ClIm(CH 2 ) 11 -COOH was fully dissolved in PBS with pH=5~8 under stirring, then 150mg 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride and 200mg N-hydroxysuccinimide were added Amine, stirred at room temperature for 15-60min. 100 μL of aminated carbon nano...

Embodiment 2

[0037] This embodiment provides a redox ligand-based conductive nanomaterial glucose sensing material, the preparation process of which includes the following steps:

[0038] A. Weigh 1-100mg of graphene into a 10mL vial, add 1-3mL of deionized water and 0.01-1mL of methacryloxypropyltrimethoxysilane, and sonicate for 10-100min to obtain a uniform dispersion solution, placed at 25-50°C for 1-24 hours, 0.1-100 μL of 0.1M hydrochloric acid was added to it, left at room temperature for 6-48 hours, the obtained suspension was dialyzed, and the dialyzed suspension was washed by centrifugation several times to obtain based graphene.

[0039] B. Add 10~100mg Os(diamino-bpy) 2 ClIm(CH 2 ) 11 -NH 2 Fully dissolve in ethanol under stirring, add 100 μL of acryloyloxy-modified graphene dispersion solution with a concentration of 200 mg / mL, and stir at 40-90° C. for 1-12 hours. After the reaction is completed, the obtained product is washed by centrifugation with ethanol, and then dia...

Embodiment 3

[0042] This embodiment provides a redox ligand-based conductive nanomaterial glucose sensing material, the preparation process of which includes the following steps:

[0043] A. Weigh 1-100mg of nano-conductive carbon black and place it in a 10mL vial, add 1-3mL of deionized water and 0.01-1mL of γ-glycidyl etheroxypropyl trimethoxysilane, and sonicate for 10-100min to obtain a uniform The dispersion liquid was placed at 25-50°C for 1-24 hours, 0.1-100 μL of 0.1M hydrochloric acid was added to it, and it was left at room temperature for 6-48 hours. The obtained suspension was dialyzed, and the dialyzed suspension was washed by centrifugation several times to obtain a ring on the surface. Oxygen nano conductive carbon black.

[0044] B. Add 10~100mg Os(dimethyl-bpy) 2 ClIm(CH 2 ) 11 -NH 2 Fully dissolve in ethanol under stirring, add 100 μL of epoxy-modified conductive carbon black dispersion with a concentration of 200 mg / mL, and stir at 40-90° C. for 1-12 hours. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com