Method for measuring surface clearance and surface difference of reflection difference workpiece

A workpiece surface and difference technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to accurately obtain gap surface difference values, poor light strip collection quality, reduce equipment costs, etc., achieve short image capture time, The effect of fast adjustment speed and reduced equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

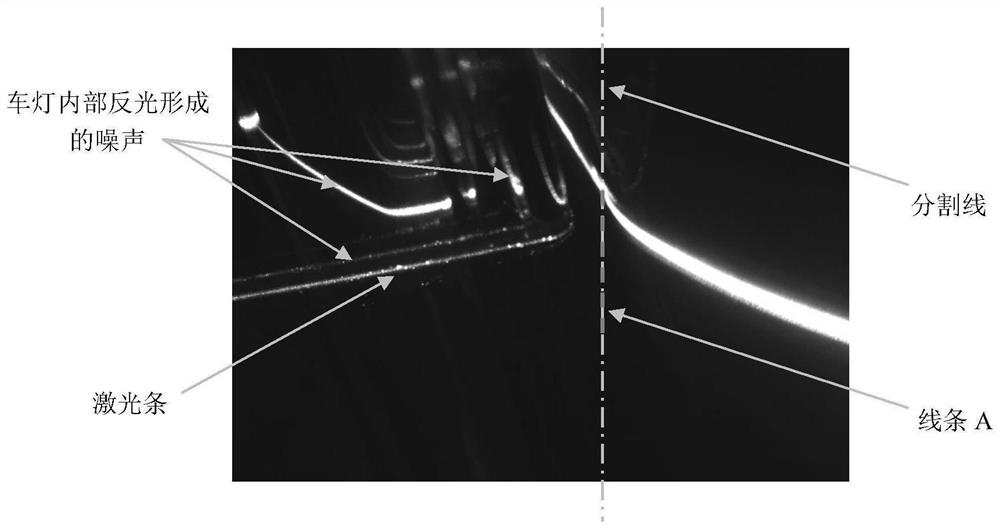

[0044] A method for measuring the surface gap and surface difference of workpieces with reflective differences. The workpieces with reflective differences include areas with different reflectivity. The surface with high reflectivity is recorded as bright surface, and the surface with low reflectivity is recorded as dark surface. gaps and / or flush features formed between them;

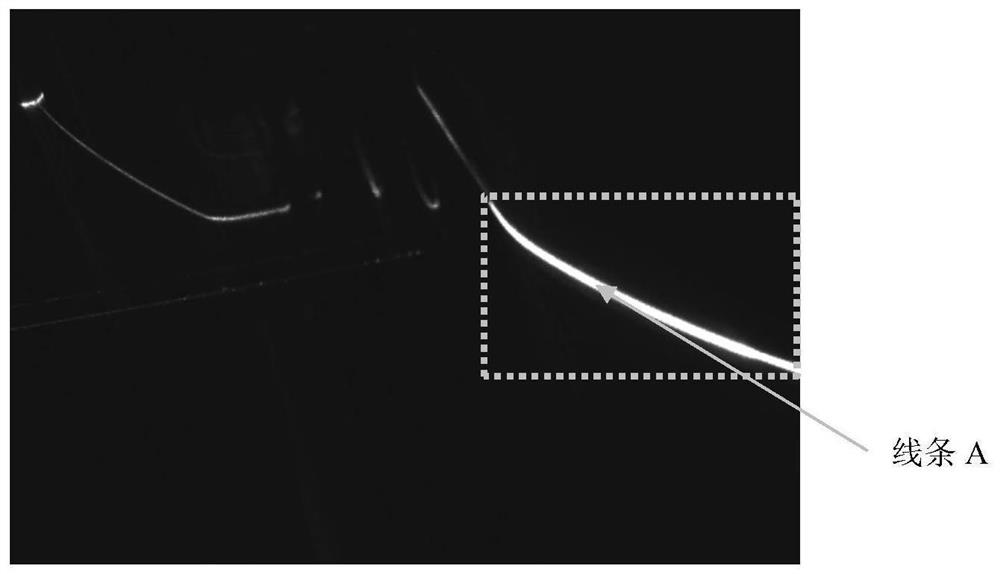

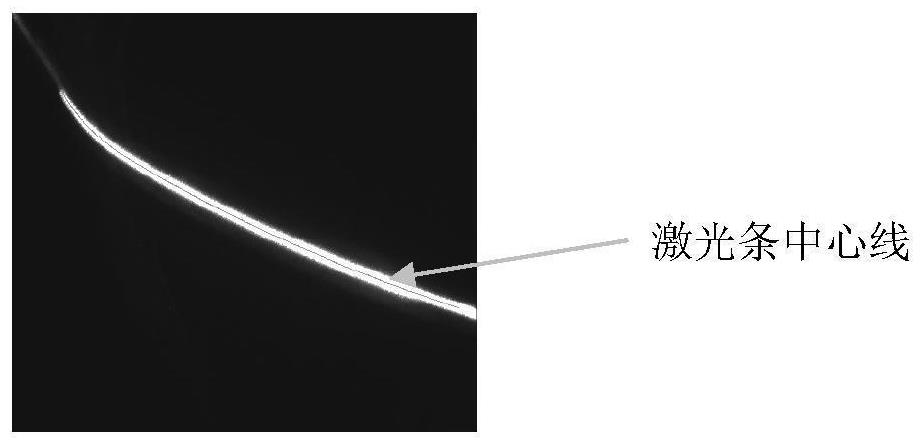

[0045]Move the measurement equipment to the vicinity of the gap and / or surface difference feature, the measurement equipment includes a camera and a line laser; the line laser projects a laser bar to the feature position, and the camera continuously collects two laser bar images; according to the laser bar on the two laser bar images The brightness is recorded as low-brightness laser bar image and high-brightness laser bar image respectively;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com