Industrial process operation state evaluation method based on supervision probability slow feature analysis

A technology of operating status and industrial process, applied in program control, comprehensive factory control, electrical test/monitoring, etc., can solve problems such as lack of evaluation of useless information, inaccurate extraction of process information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] The present invention will be further described below.

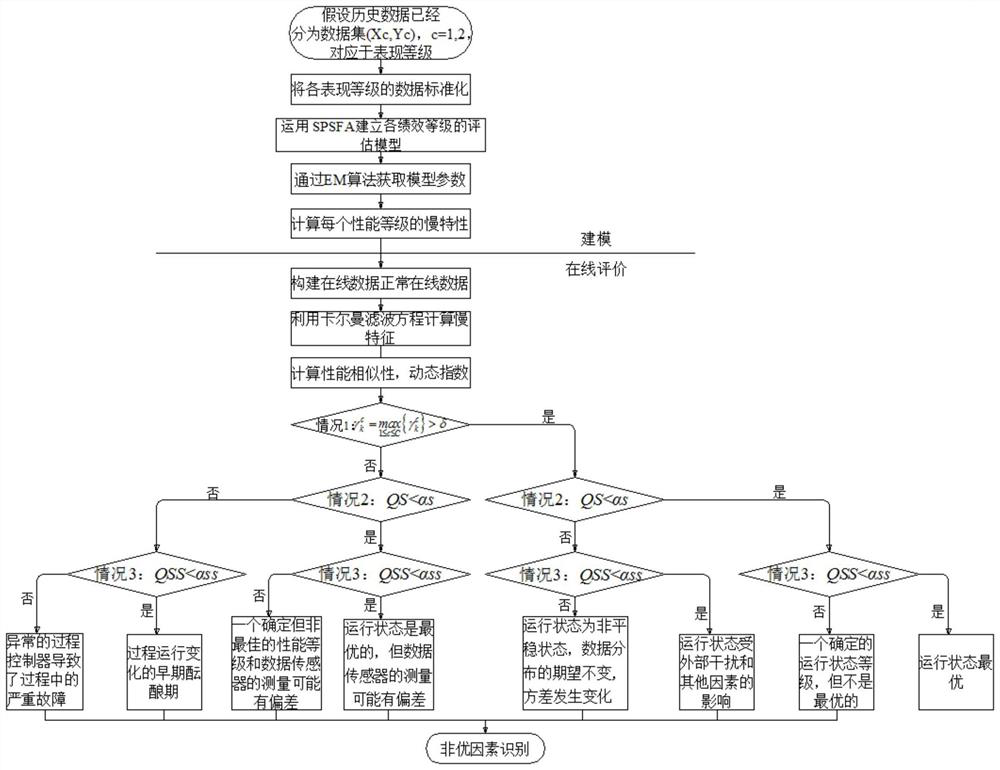

[0115] The present invention provides an industrial process operating state evaluation method based on supervised probability slow feature analysis, comprising the following steps:

[0116] Step 1: Use the SPSFA algorithm to perform static-dynamic characteristic collaborative sensing information mining, and establish an offline evaluation model for running state evaluation;

[0117] S11: Collect the data generated during the production process and divide the data into the input matrix X ∈ R N×m and the output matrix Y∈R N , where N is the number of samples, m is the number of variables, R is the set of real numbers, and R N×m Represents a real matrix of N × m dimensions;

[0118] S12: Perform zero mean and unit variance processing on each column of the input matrix X, denoted as input matrix X a , and denote the difference between two consecutive input data points in time in each column as ΔX a ; Standardize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com