Method for harmless treatment of barium slag and synchronous recovery of barium carbonate

A barium carbonate and barium slag technology, applied in barium carbonate, calcium carbonate/strontium/barium, grain processing and other directions, can solve the problems of uneven mixing of materials, waste of resources, poor pertinence, etc., to improve the mixing uniformity and reduce the environment. Pollution, targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

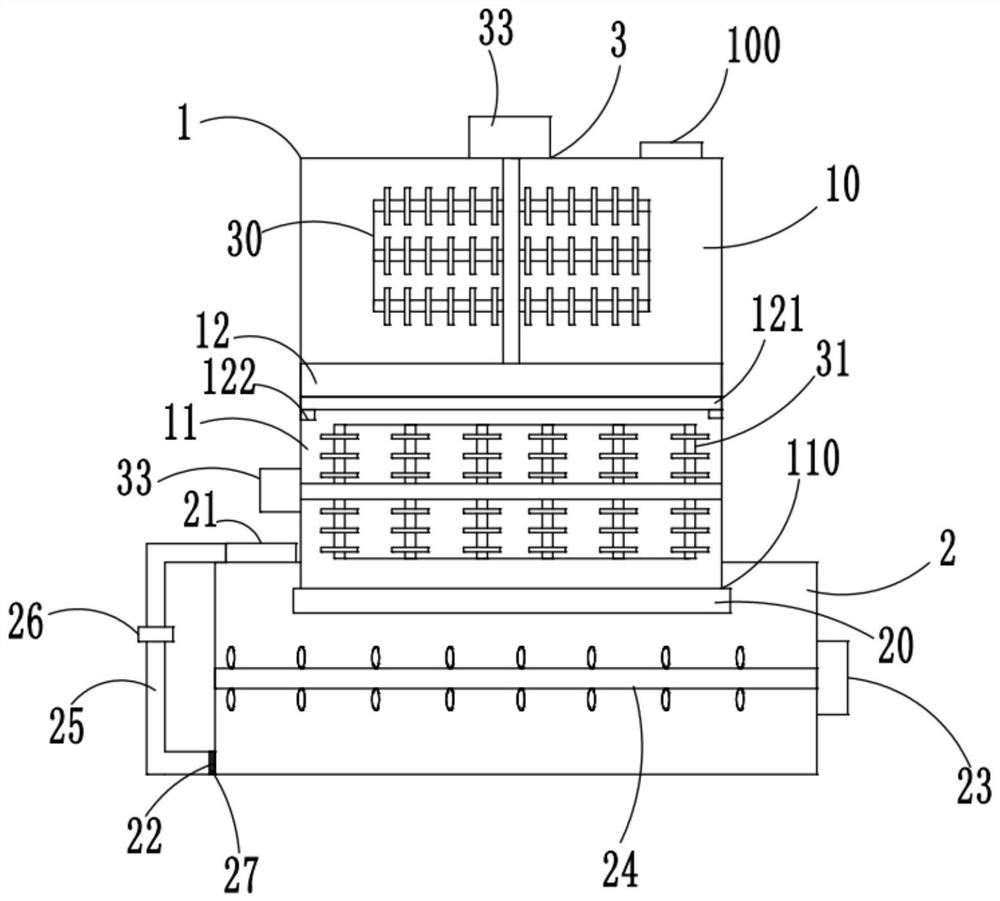

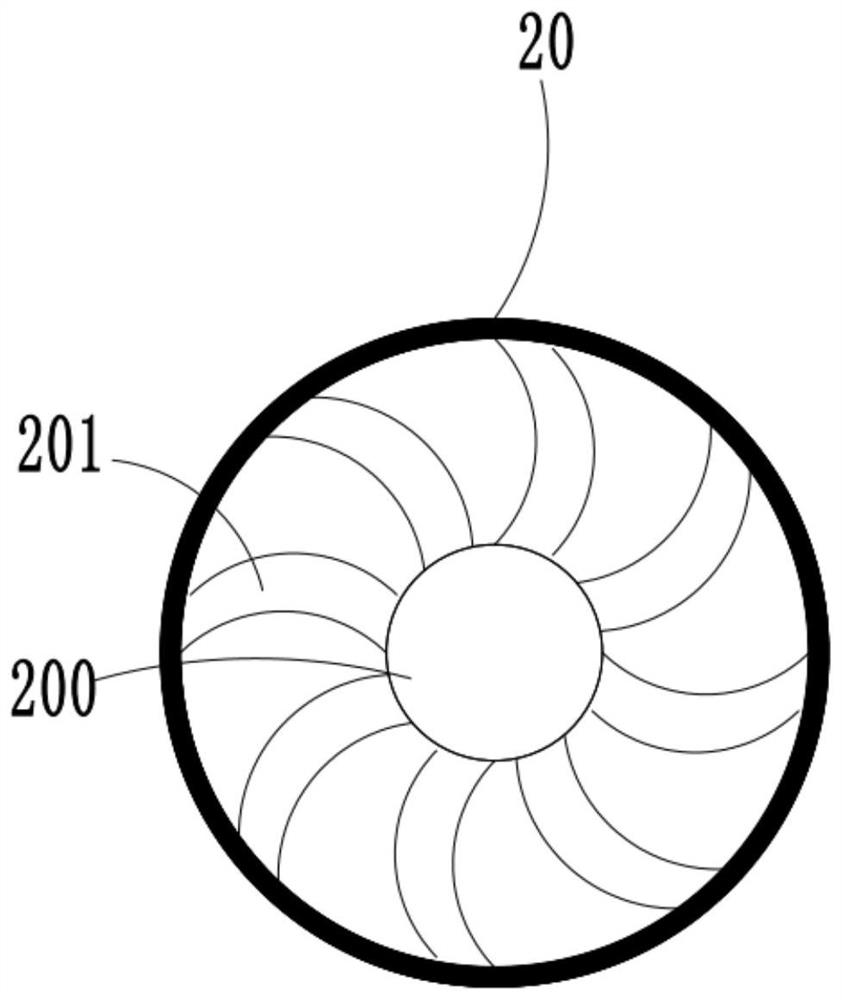

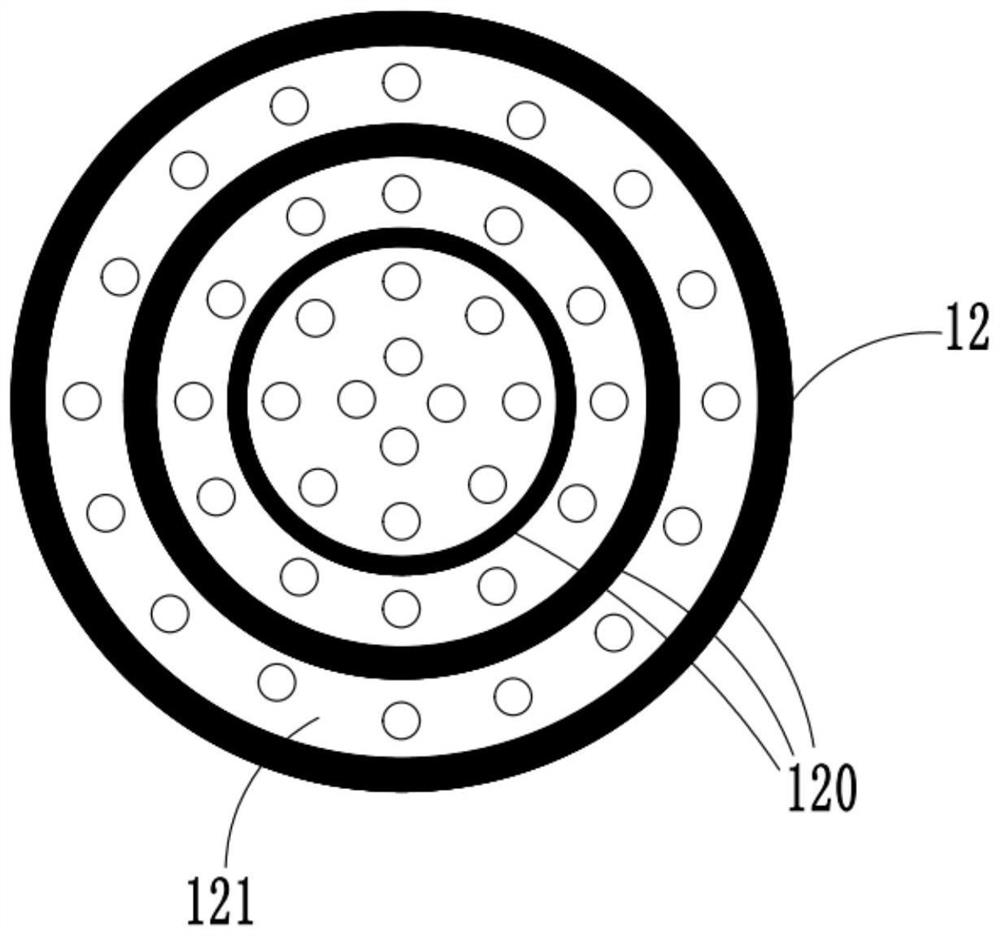

Method used

Image

Examples

Embodiment 1

[0031] A method for making barium slag harmless and synchronously recovering barium carbonate, said barium slag is the barium-containing waste slag produced after dephosphorizing high-phosphorus molten iron using barium-based slag system, and its main component is Ba 3 (PO 4 ) 2 and soluble barium salts, comprising the steps of:

[0032] S1, put the barium-containing waste slag into a grinder, grind and sieve to obtain a barium slag fine powder with a mesh number of 80, fully dissolve the barium slag fine powder in water to obtain a soluble barium salt solution and Ba 3 (PO 4 ) 2 Precipitated mixed slurry;

[0033] S2, after separating the soluble barium salt solution in the above mixed slurry, take 3.5g soluble barium salt solution and mix it with 15ml dilute hydrochloric acid solution, and after ultrasonic vibration treatment for 30min at a temperature of 35°C, barium chloride solution A is obtained, and then , will (NH 4 ) 2 CO 3 Dissolve in deionized water and prep...

Embodiment 2

[0037] A method for making barium slag harmless and synchronously recovering barium carbonate, said barium slag is the barium-containing waste slag produced after dephosphorizing high-phosphorus molten iron using barium-based slag system, and its main component is Ba 3 (PO 4 ) 2 and soluble barium salts, comprising the steps of:

[0038] S1. Put the barium-containing waste slag into a grinder, grind and sieve to obtain a barium slag fine powder with a mesh number of 90, fully dissolve the barium slag fine powder in water to obtain a soluble barium salt solution and Ba 3 (PO 4 ) 2 Precipitated mixed slurry;

[0039] S2, after separating the soluble barium salt solution in the above-mentioned mixed slurry, take 3.5g soluble barium salt solution and mix with 15ml dilute hydrochloric acid solution, after ultrasonic vibration treatment under the temperature condition of 40 ℃ for 30min, obtain barium chloride solution A, then , will (NH 4 ) 2 CO 3 Dissolve in deionized water...

Embodiment 3

[0043] A method for making barium slag harmless and synchronously recovering barium carbonate, said barium slag is the barium-containing waste slag produced after dephosphorizing high-phosphorus molten iron using barium-based slag system, and its main component is Ba 3 (PO 4 ) 2 and soluble barium salts, comprising the steps of:

[0044] S1. Put the barium-containing waste slag into a grinder, grind and sieve to obtain a barium slag fine powder with a mesh number of 100, and fully dissolve the barium slag fine powder in water to obtain a soluble barium salt solution and Ba 3 (PO 4 ) 2 Precipitated mixed slurry;

[0045] S2, after separating the soluble barium salt solution in the above-mentioned mixed slurry, take 3.5g soluble barium salt solution and mix with 15ml dilute hydrochloric acid solution, after ultrasonic vibration treatment under the temperature condition of 45 ℃ for 30min, obtain barium chloride solution A, then , will (NH 4 ) 2 CO 3 Dissolve in deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com