Modularized disconnected type drive axle and all-terrain crane

A disconnected drive axle and modular technology, applied in mechanical equipment, running mechanism, transmission device, etc., can solve problems such as optimization, unfavorable vehicle structure, and cost reduction, and achieve strong adaptability, standardization, and complete vehicle The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

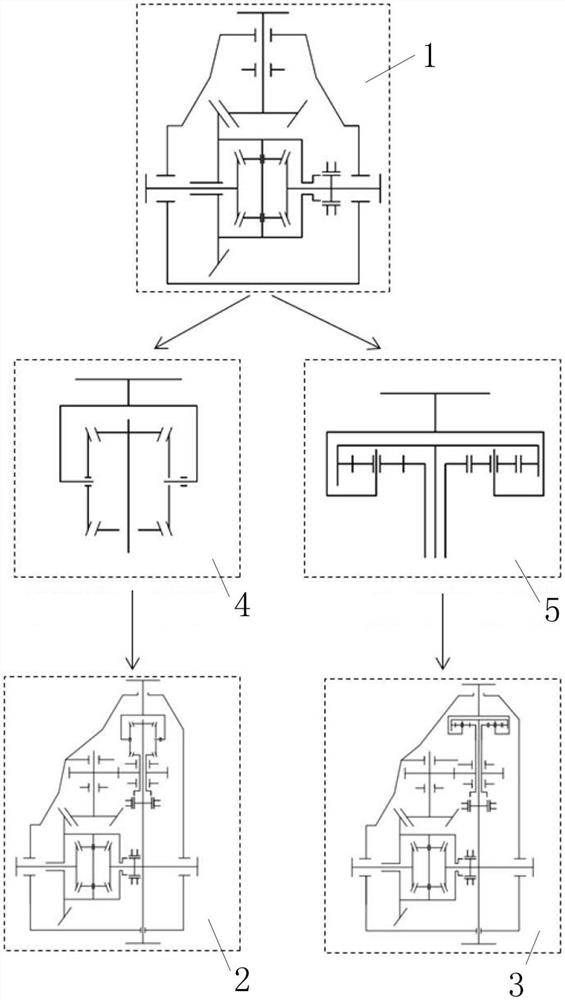

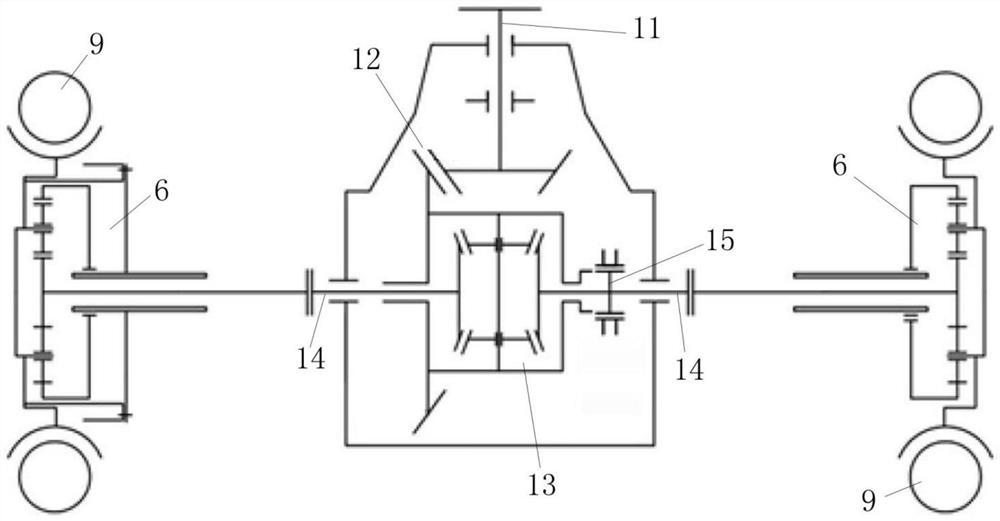

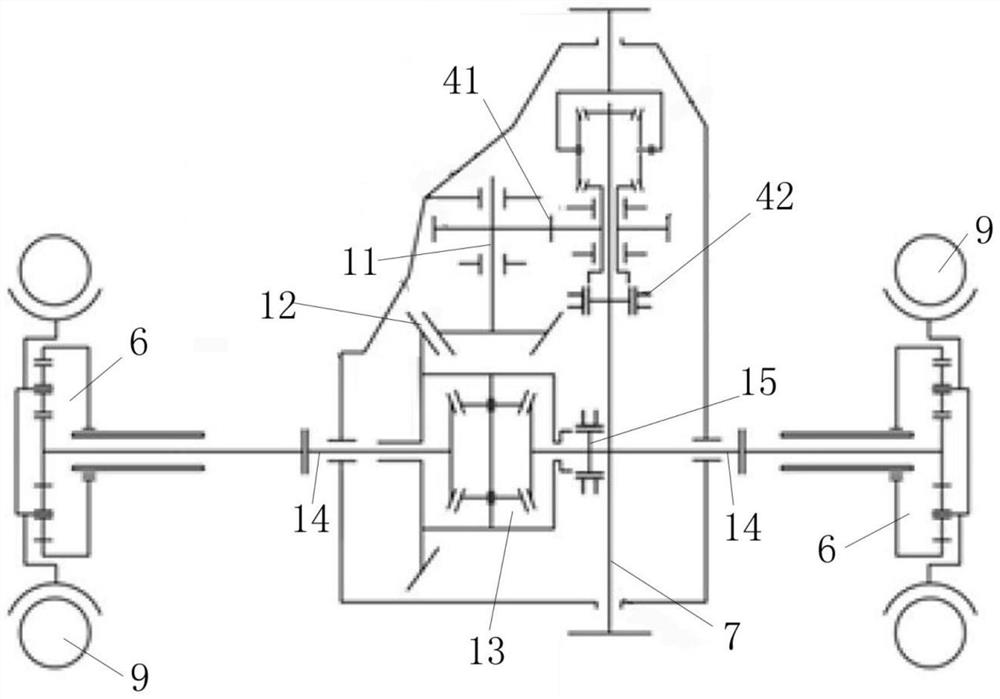

[0024] Such as Figure 1~Figure 4 As shown, a modular disconnected drive axle includes a main reduction module and a wheel side module 6, the input end of the main reduction module is connected to the output end of the transfer case, and the engine drives the main reduction module through the transfer case; The output end of the main reduction module is connected to the input end of the wheel side module 6; the wheel side module 6 is connected to the wheel 9 through transmission; the main reduction module includes a non-through main reduction module 1, a through main reduction module 2, and a triple drive through main reduction module At least one of 3; the wheel side module 6 includes one of the first wheel side module, the second wheel side module and the third wheel side module, wherein the speed ratio of the first wheel side module<the speed ratio of the second wheel side module The speed ratio of < the speed ratio of the third wheel side module.

[0025] In this embodime...

Embodiment 2

[0044] Based on the modular disconnected driving axle described in the first embodiment, this embodiment provides an all-terrain crane configured with the modular disconnected driving axle described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com