Defect detection method and detection system for mask plate

A technology of defect detection and reticle, which is applied in the field of defect detection method and detection system of reticle, which can solve the problems of limited resolution ability, curved surface mirror cannot detect defects, etc., and achieve the effect of improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

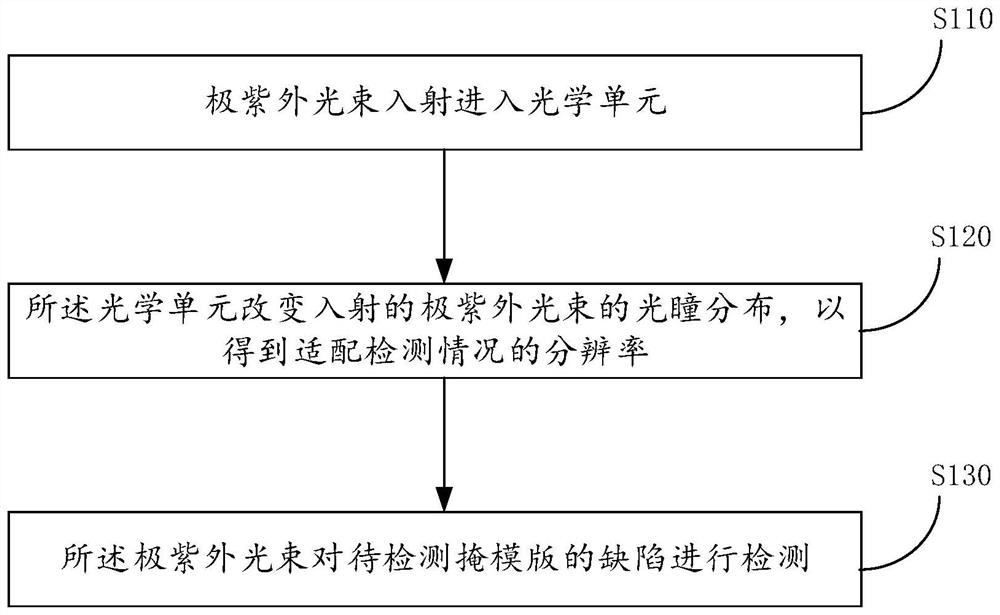

[0034] see figure 1 , a flow chart of the steps of the defect detection method for the reticle provided by the present application, including the following steps:

[0035] Step S110: the EUV light beam is incident into the optical unit.

[0036] Step S120: the optical unit changes the pupil distribution of the incident EUV light beam to obtain a resolution adapted to the detection situation.

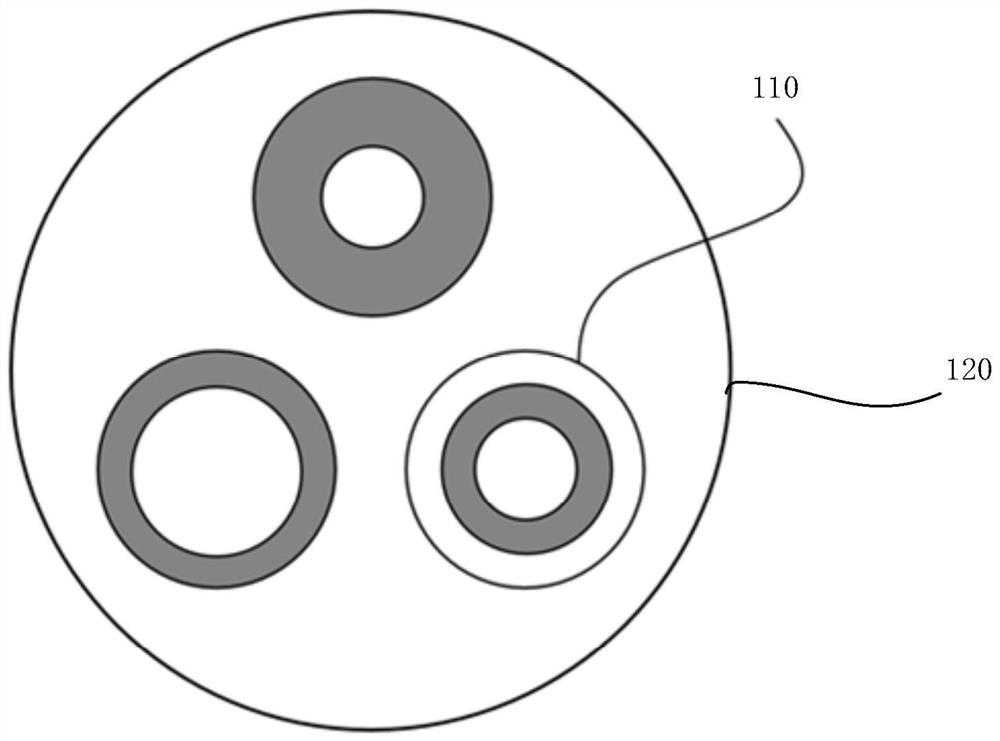

[0037] see figure 2 , is a schematic structural diagram of the optical unit provided by an embodiment of the present application.

[0038] In this embodiment, the optical unit includes coherent plates 110 with different coherence factors. The coherent plates 110 are mounted on a rotating disk 120 , and the rotating disk 120 is positioned at a proper position in the optical path by the rotation of the rotating disk 120 .

[0039] It can be understood that the coherent plates with different coherence factors are pre-installed on a rotating disk, and according to the structure of the op...

Embodiment 2

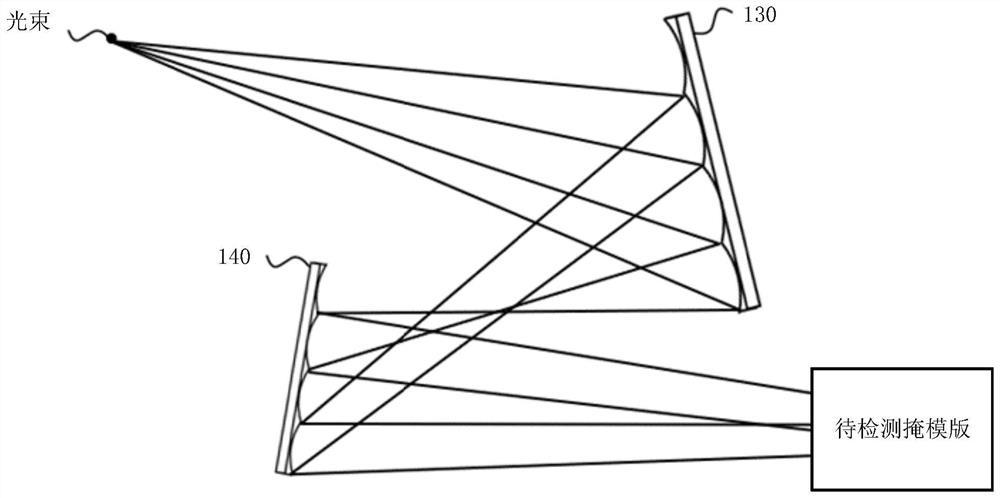

[0046] see again image 3 The present application also provides a defect detection system for a reticle, including: a light source module, including a light source for providing an extreme ultraviolet light beam; an optical unit, which can change the pupil distribution of the incident extreme ultraviolet light beam, to A resolution adapted to the detection situation is obtained; a detection unit is provided with a reticle to be detected, and the extreme ultraviolet light beam detects defects of the reticle to be detected.

[0047] In some of the embodiments, the optical unit includes coherent plates with different coherence factors, the coherent plates are installed on a rotating disk, and the rotating disk is positioned at a proper position in the optical path through the rotation of the rotating disk.

[0048]It can be understood that the coherent plates with different coherence factors are pre-installed on a rotating disk, and according to the structure of the optical path,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com