Shallow hole reinforcing method suitable for high-temperature geothermal well

A high-temperature geothermal and geothermal well technology, applied in geothermal energy, household heating, geothermal power generation, etc., can solve the problems of adverse impacts on villagers' life and production, gas explosion, and changes in thermal display forms, and reduce gas explosion and collapse risk, ensure safety, reduce the effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

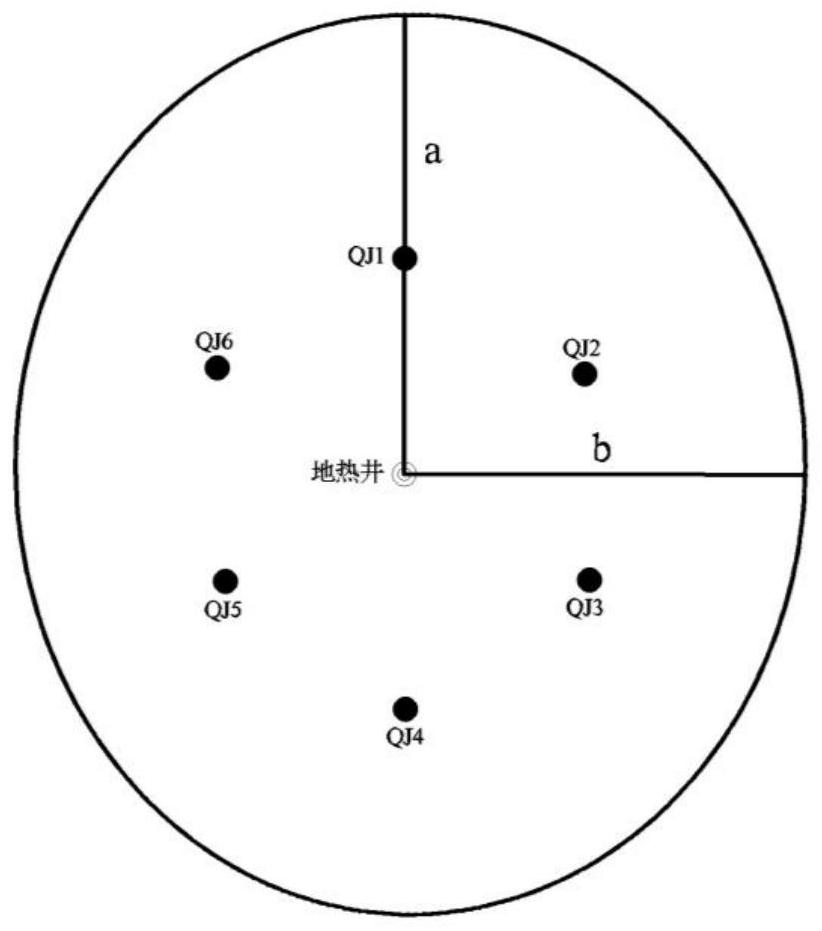

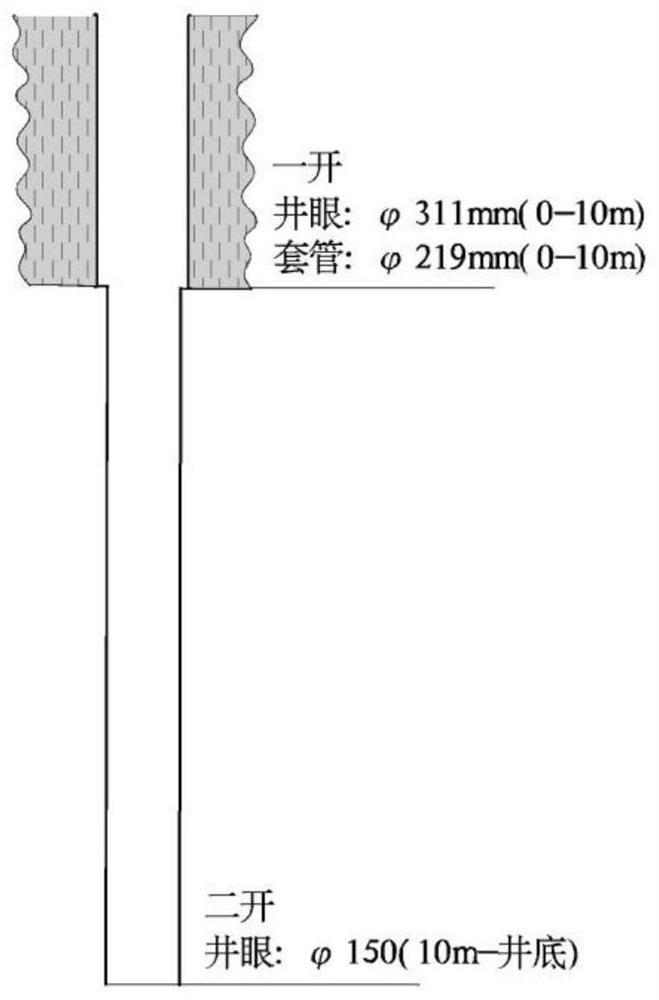

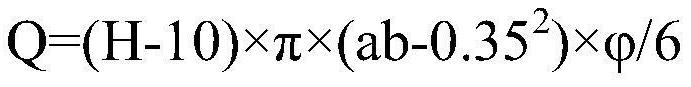

[0079] Taking Gulu high-temperature geothermal wells as an example, a shallow hole reinforcement method suitable for high-temperature geothermal wells is provided, which specifically includes the following steps:

[0080] The construction of Gulu ZK101 well will take place from September to October 2020. It is located in the thermal display area of the geothermal field. There are vents, boiling springs, and hot springs within 50m around the geothermal well. During the construction of the geothermal well, the spring water 30m away from the wellhead Cloudiness occurs. The Gulu geothermal field is located in the Naqu-Yangbajing geothermal zone, and the main thermal structure is 20° northeast in this area. The 0-60m of the well is Quanhua, and the 65-70m is the weathered shell type shallow high-temperature heat storage. During the well completion test blowout process, if the blowout time exceeds 5 minutes, a large amount of water vapor gushes out around the wellhead, which affec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com