Spiral forced-feeding device, shaping system with same and degassing method

A technology of forced feeding and forming processing, applied in material forming presses, manufacturing tools, packaging, etc., can solve problems such as inability to solve exhaust problems, equipment vibration, inability to form, and reduce the phenomenon of gas explosion, forming rate The effect of improving and stable molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but those skilled in the art should understand that such descriptions are merely illustrative and are not intended to limit the scope of the present invention.

[0026] In general, the screw forced feeding device of the present invention is mainly used for the forming and processing of powdery materials, but is not limited to this, for example, it can also be used for feeding fine granular materials. In the present invention, the powdery material is preferably a powdery material without a binder or with a very small amount of binder, or the powdery material itself is a non-sticky or very low-viscosity powdery material. Examples of powdery materials may include, but are not limited to, pulverized coal, powdered cinder, and the like.

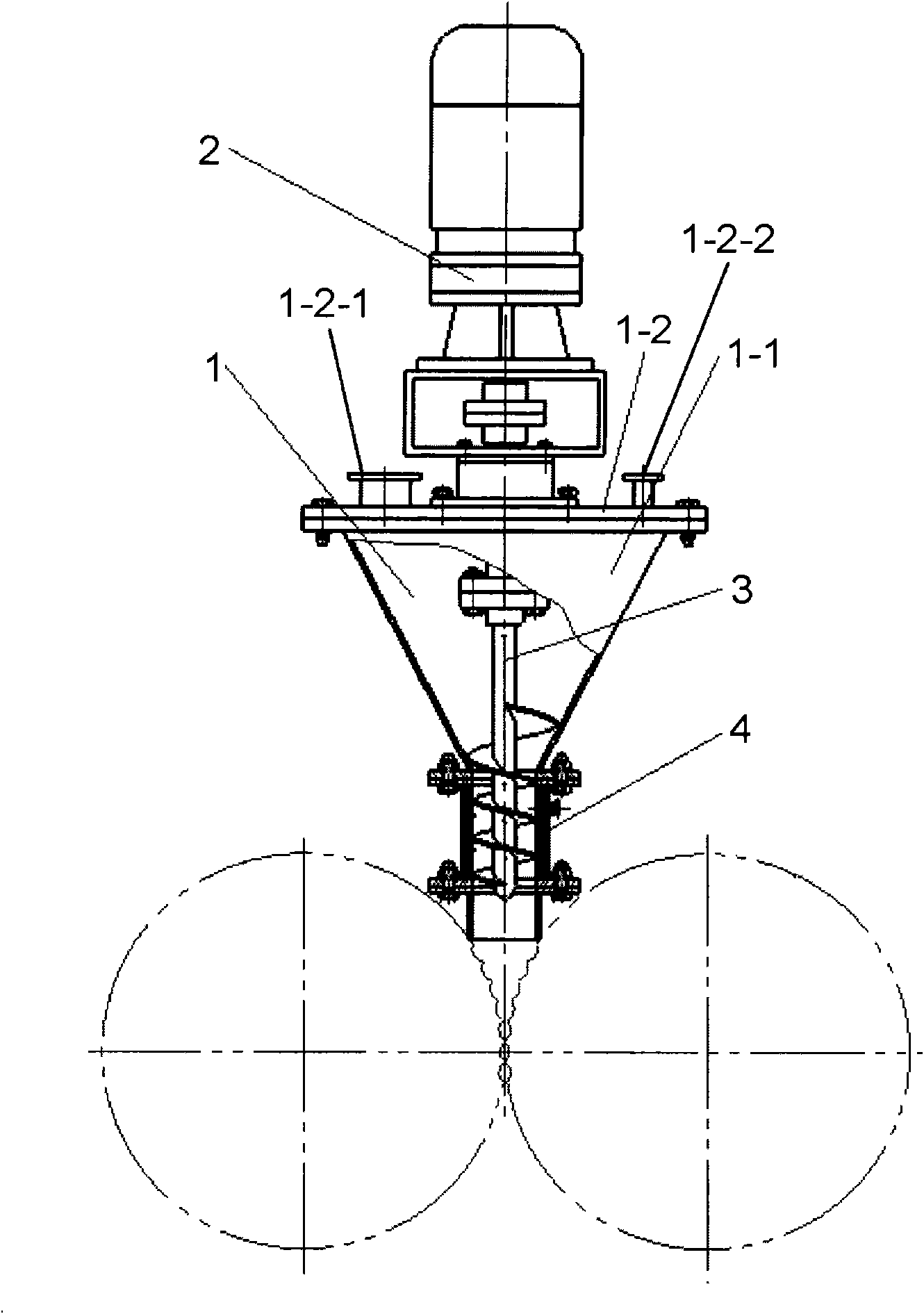

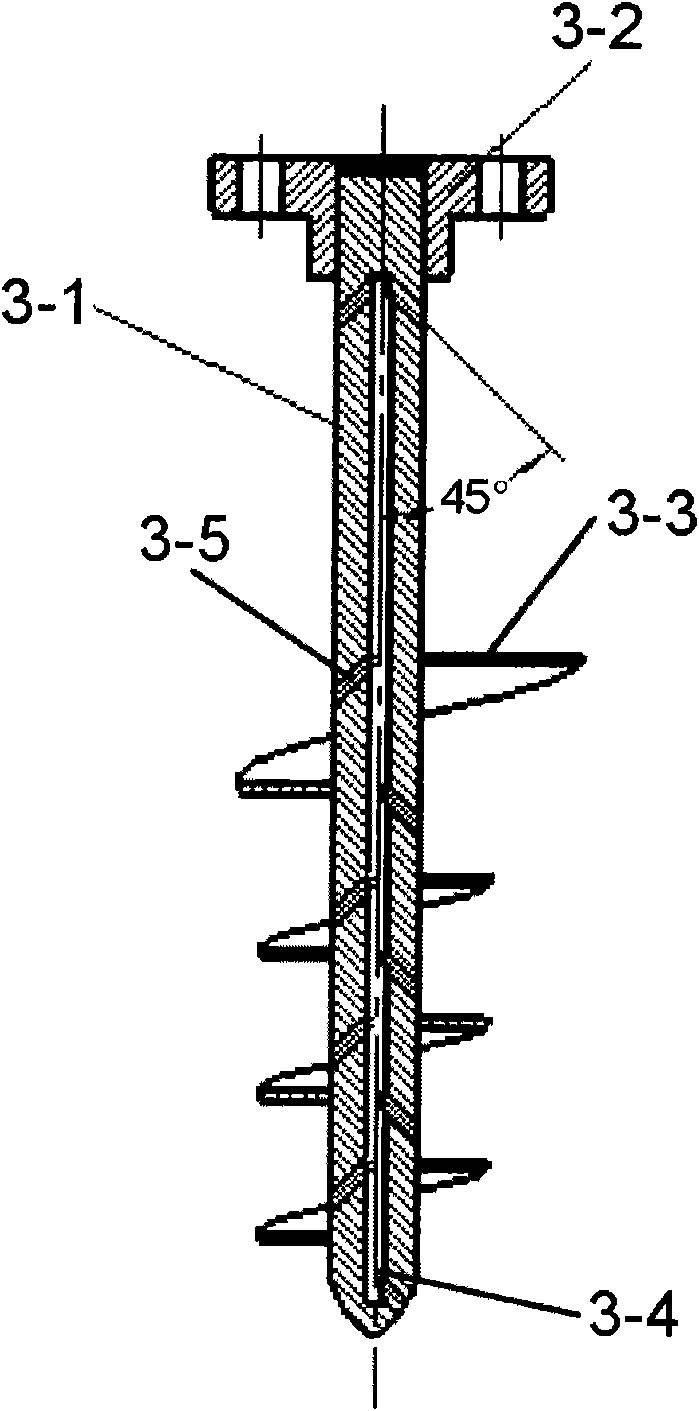

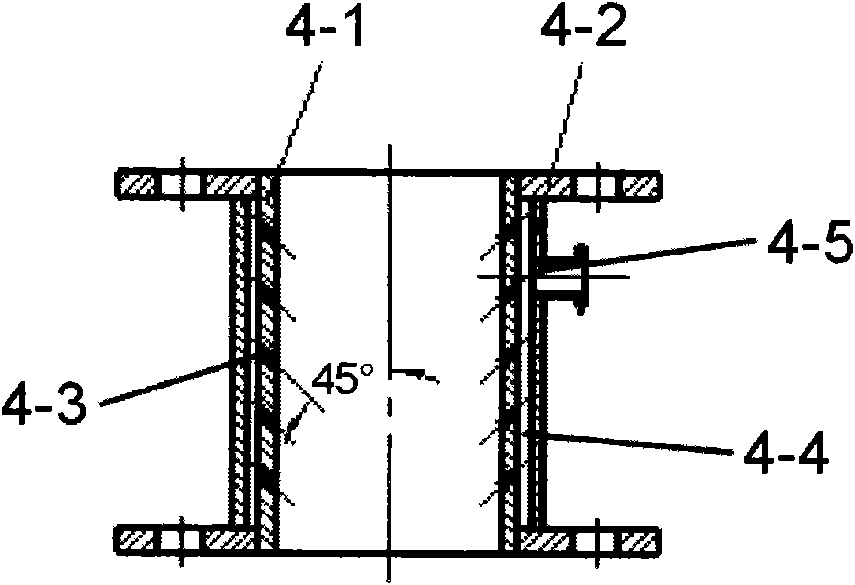

[0027] Reference figure 1 , figure 1 Illustratively shows a schematic structural diagram of a screw forced feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com