Hollow aerated concrete slab with reinforcing columns and processing method of hollow aerated concrete slab

A technology of aerated concrete slabs and processing methods, which is applied in the fields of building assembly and thermal insulation, and can solve problems such as difficulty in maintaining the rigidity of wall panels, inability to meet the safety of building structures, and inability to ensure structural safety, so as to solve the problem of peeling off of exterior wall paint , Solve the difficulty of installation and improve the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

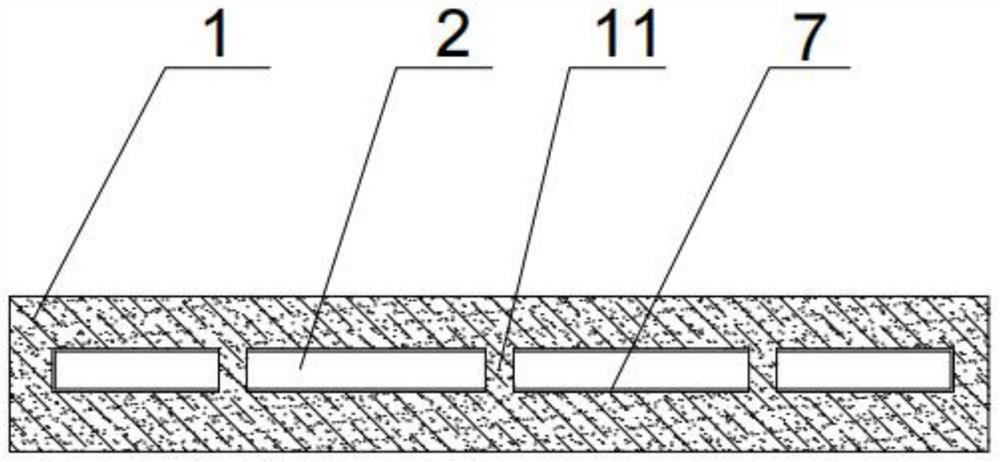

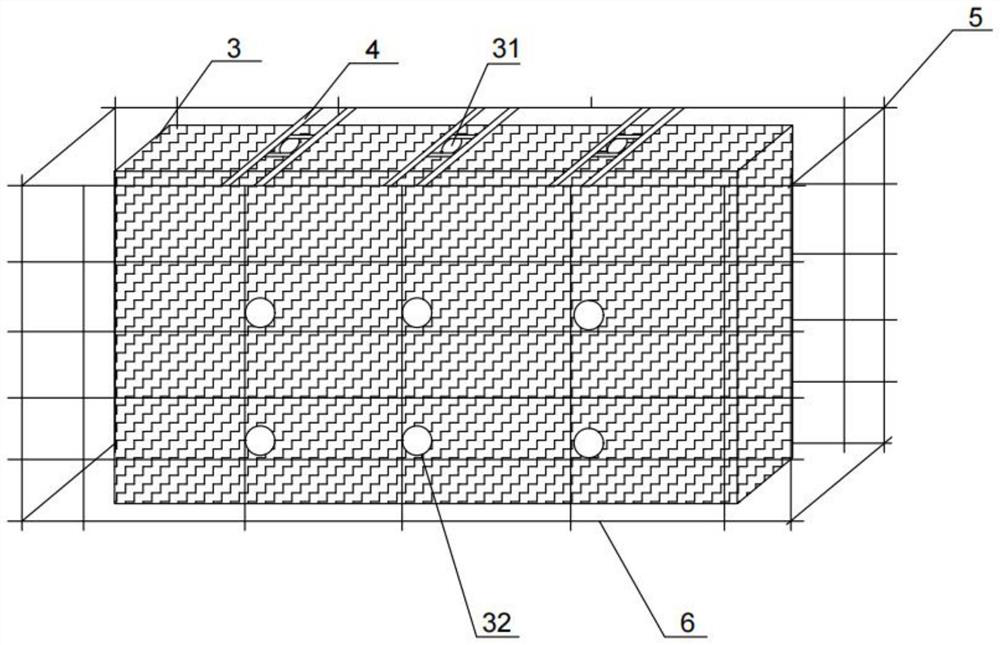

[0042] refer to figure 1 A hollow aerated concrete slab with reinforced columns is shown, including a base plate 1, a closed cavity 2 is formed inside the base plate 1, and a plurality of reinforced columns 11 are formed in the cavity 2; and An organic thermal insulation and waterproof layer 7 is formed on the inner wall of the cavity 2 and the outer wall of the reinforcing column 11; the organic thermal insulation and waterproof layer 7 is a coating formed after the organic thermal insulation board 3 is melted; the hollow cavity is filled with Polyurethane insulation.

[0043] In this embodiment, the reinforcing column 11 is integrally formed with the base plate 1 .

[0044] In this embodiment, the present invention also provides a method for processing a hollow aerated concrete slab with reinforced columns, comprising the following steps:

[0045] 1) After drawing and straightening the reinforcing bar, the reinforcing bar mesh 6 is obtained by welding;

[0046] 2) According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com