Large-island saline-alkali bacillus capable of producing cyclodextrin glucosyltransferase and application of large-island saline-alkali bacillus

A bacillus and glucose-based technology, applied in the field of enzyme engineering, can solve the problems of few species and high price, and achieve the effects of high conversion rate, low material cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

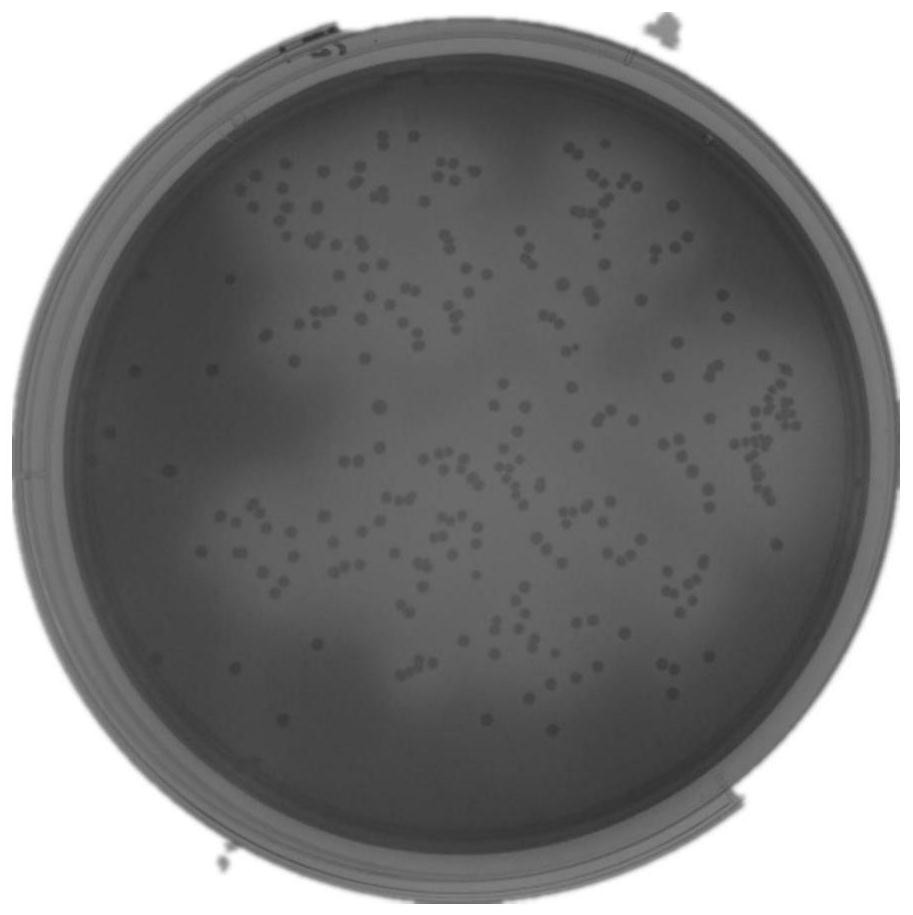

[0035] Embodiment 1: strain screening

[0036] From the soil of the stevia planting base of Zhucheng Haotian Pharmaceutical Co., Ltd. in Shandong Province, 10 soil samples were taken according to the "five-point sampling method", and the strains were isolated from them. Weigh 5g of the sample and add it to a small Erlenmeyer flask filled with 45ml of sterile normal saline, shake it on a shaker at 150rpm at 28°C for 1 hour, draw 0.5ml of soil bacteria suspension and place it in 4.5ml of sterile normal saline, mix well, and dilute gradually 10 -1 、10 -2 、10 -3 、10 -4 and 10 -5 5 gradients. Draw 100 μL from the bacterial suspension of each dilution gradient and spread it on the separation and screening plate, and incubate at 28°C and 37°C incubators for 2 days respectively. Select the strain that produces a yellow transparent circle on the plate as the strain that produces CGTase. Pick a single colony and streak the plate 4 times. Afterwards, after the bacteria obtained ...

Embodiment 2

[0039] Embodiment 2: fermentation produces enzyme

[0040] (1) Fermentation culture: Inoculate the bacterial strain screened in Example 1 into the fermentation medium, culture at 28° C. for 2-3 days, and collect the supernatant by centrifugation to obtain the crude enzyme liquid. Fermentation medium (g / L): soluble starch 10, peptone 5, yeast powder 5, dipotassium hydrogen phosphate 1, magnesium sulfate heptahydrate 0.2, sodium carbonate 5, among which sodium carbonate was first formulated to 30% (w / v) The mother liquor was sterilized separately and then added to the culture medium, and autoclaved at 121°C for 20 minutes. Natural pH.

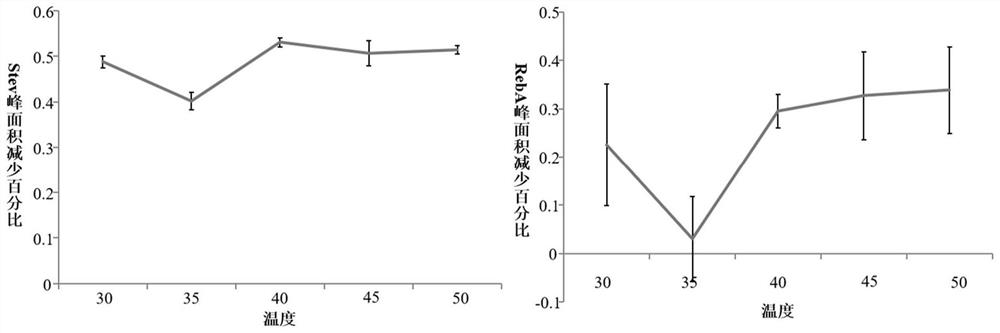

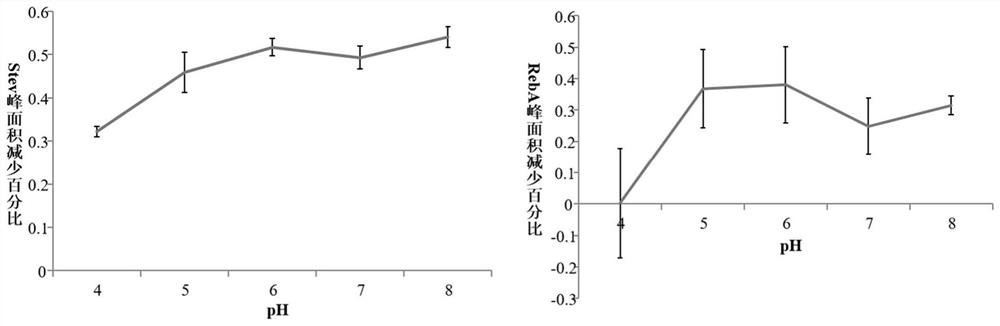

[0041] (2) Product identification: prepare 2% (w / v) steviol glycoside (Zhucheng Haotian Pharmaceutical Co., Ltd. SG90) + 2% (w / v) soluble starch solution, add crude enzyme solution (culture medium 10000rpm, centrifuge 20min , take the supernatant), and react at 28-50°C for 24-48h. The resulting reaction solution was filtered through a 0.22 μm ...

Embodiment 3

[0044] Embodiment 3: the concentration of crude enzyme liquid

[0045] Concentrate the enzyme solution obtained in Example 2 with an ultrafiltration centrifuge tube Millipore 15ml / 10kd (concentrate 100 times), and exchange the buffer (> 1000 times) to remove the medium components, so that the enzyme is placed in ultrapure water to avoid Impurities are introduced in subsequent reactions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com