Cement-based fly ash floating bead sound absorption material and preparation method thereof

A technology of fly ash floating beads and fly ash, which is applied in the field of sound-absorbing materials, can solve problems such as poor noise reduction effects, and achieve the effects of improving sound absorption performance, good acoustic performance, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

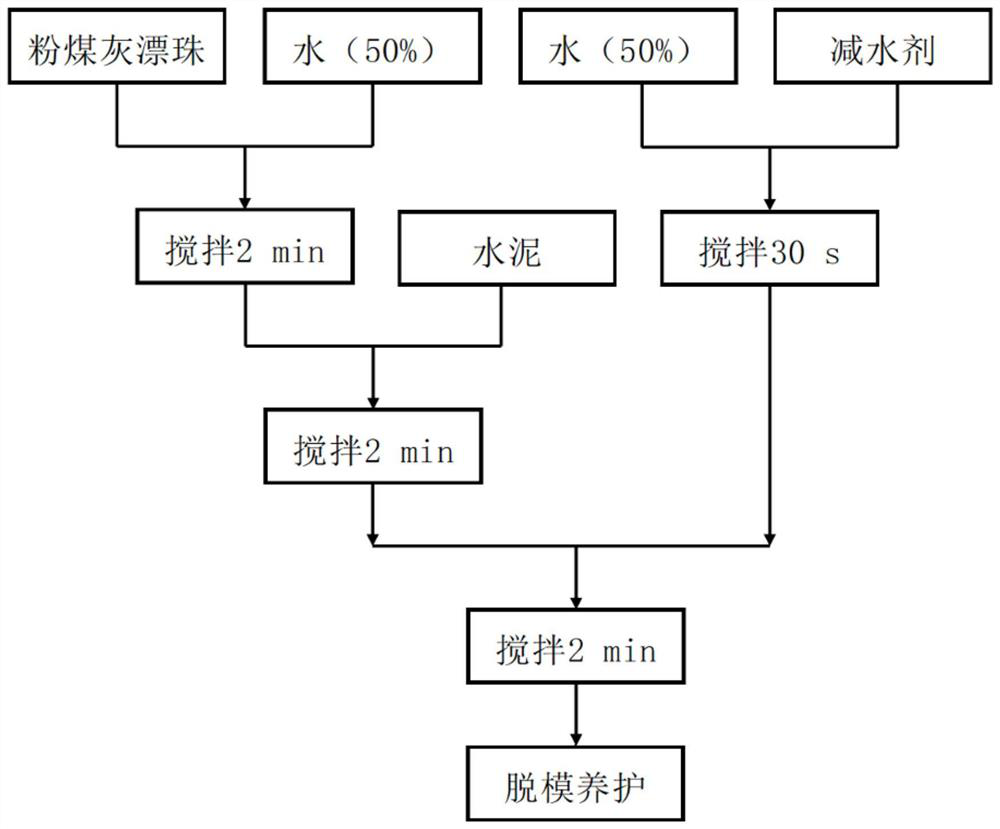

[0033] The second aspect of the embodiment of the present application provides a method for preparing a cement-based fly ash floating bead sound-absorbing material, including the following steps:

[0034]Step S10: According to the above-mentioned embodiment of the present application, the components contained in the cement-based fly ash floating bead sound-absorbing material are provided and the raw material components are weighed;

[0035] Step S20: mixing each raw material component and a solvent to obtain a cement-based fly ash floating bead sound-absorbing slurry;

[0036] Step S30: solidifying the cement-based fly ash floating beads sound-absorbing slurry to obtain a cement-based fly ash floating beads sound-absorbing material.

[0037] The material prepared by the preparation method provided in the examples of this application has low bulk density and good acoustic performance. Specifically, according to the above examples of the application, the components contained in ...

Embodiment 1

[0052] This embodiment provides a cement-based fly ash floating beads sound-absorbing material, including a mixture of fly ash floating beads, cement, solvent and water reducing agent, and the mass ratio of fly ash floating beads: cement: water reducing agent It is 110:100:0.6.

[0053] This example provides a method for preparing a cement-based fly ash floating bead sound-absorbing material. Among them, the specific steps are as follows:

[0054] Step 10: Weigh each raw material component according to the mass ratio of fly ash bleaching beads: cement: solvent: water reducing agent is 90:100:35:0.6;

[0055] Step 20: mixing each raw material component to obtain cement-based fly ash floating bead sound-absorbing slurry;

[0056] Step 30: Solidifying the cement-based fly ash floating beads sound-absorbing slurry to obtain a cement-based fly ash floating beads sound-absorbing material.

Embodiment 2

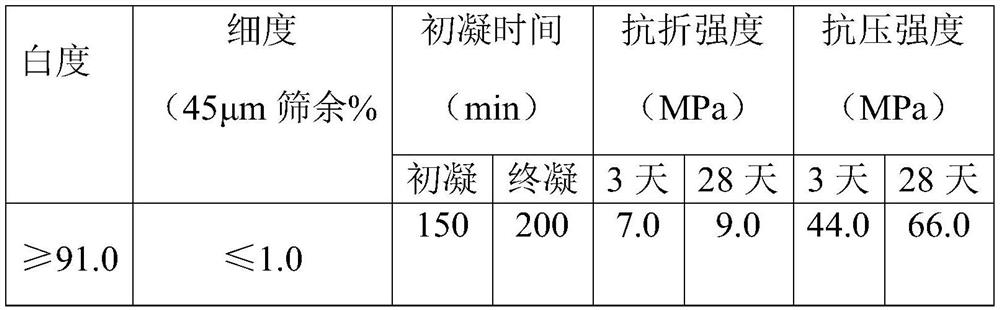

[0058] This embodiment provides a cement-based fly ash floating bead sound-absorbing material, including a mixture of fly ash floating beads, cement, solvent and water reducing agent, and fly ash floating beads: cement: solvent: water reducing agent The mass ratio is 90:100:0.6. Wherein, the fly ash floating beads are silicon oxide and aluminum oxide, and the mass ratio of silicon oxide to the aluminum oxide is 55:30 to 60:35, the diameter of the fly ash floating beads is 20 mesh, and the fly ash floating beads The ratio of wall thickness to diameter length is 1:20~2:25. The cement is 52.5R high-strength white cement. Please refer to Table 1 for the properties of the white cement. The solvent is water, and the water reducer is polycarboxylate water reducer.

[0059] Table 1 is the performance table of cement

[0060]

[0061] This example provides a method for preparing a cement-based fly ash floating bead sound-absorbing material. Specific steps are as follows:

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com