Efficient pelletizing device for preparing vehicle door post wrapper

A granulation and gatepost technology, which is applied in metal processing and other directions, can solve the problems of unfavorable particle collection, particle splashing, inconvenient particle sieving and processing, etc., and achieve the effect of avoiding splashing and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

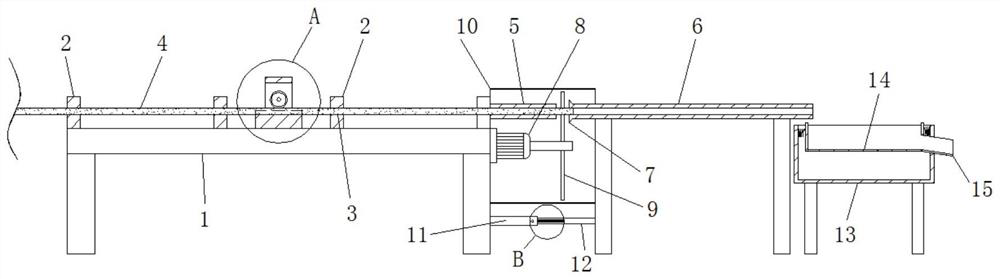

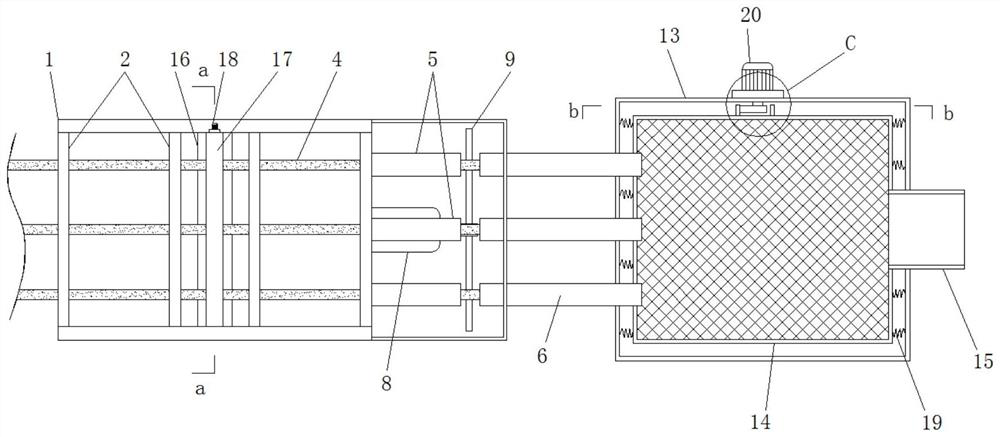

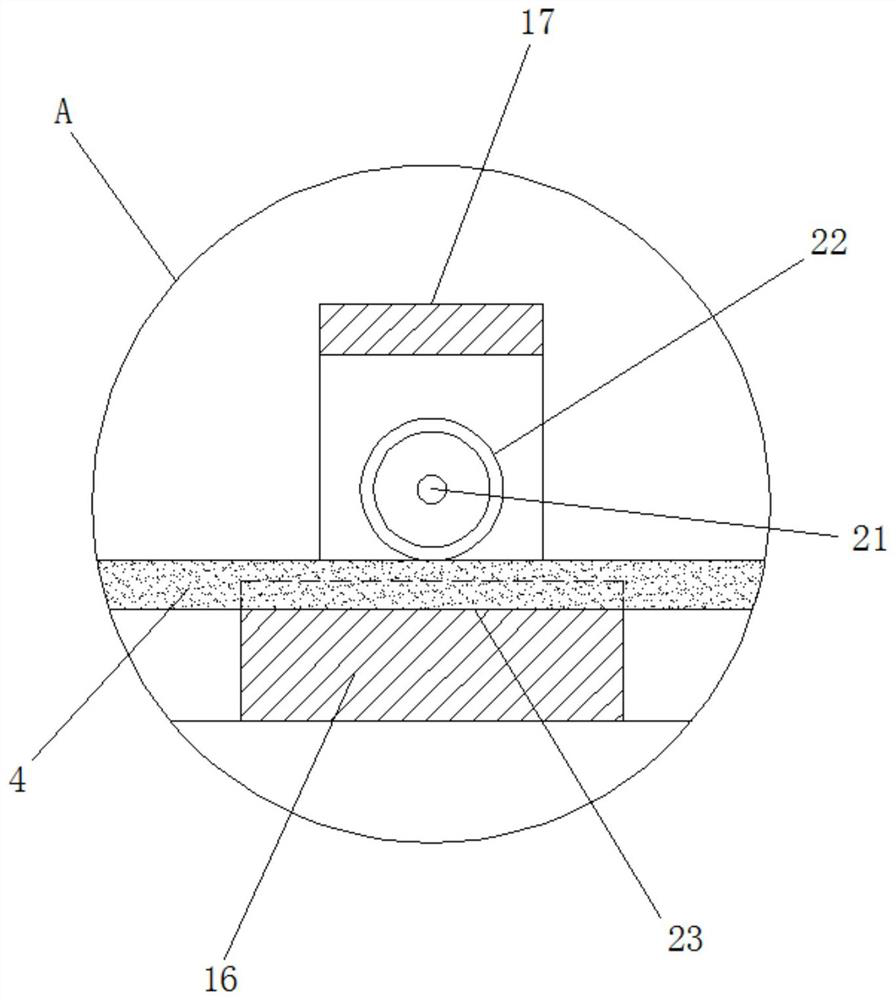

[0028] see Figure 1-8 , the present invention provides a technical solution: a high-efficiency granulation device for preparing vehicle doorpost foreskin, comprising a granulation device 1, a limiting plate 2, a sliding hole 3, a raw material strip 4, a first material guide pipe 5, a second Material guide pipe 6, bell mouth 7, material cutting motor 8, pelletizing knife 9, protective cover 10, connecting sleeve 11, connecting rod 12, collecting bin 13, collecting cover 14, material guiding chute 15, material guiding table 16, Support frame 17, transmission motor 18, support spring 19, vibrating material motor 20, rotating rod 21, transmission wheel 22, transmission groove 23, adjustment bolt 24, convex tooth groove 25, deflection wheel 26 and limit plate 27, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com