High-strength green sand pouring system of oversized traction sheave shell

A super-size, pouring system technology, applied in the direction of casting molding equipment, molds, cores, etc., can solve the problems of sand holes and hot joint feeding, increase the difficulty, etc., to solve the sand holes, reduce the pouring time, fast and stable filling type effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The directional position descriptors described in this embodiment, such as "upper", "front", "back", "left and right", etc., all refer to the general direction in which molten iron enters the gating system during casting.

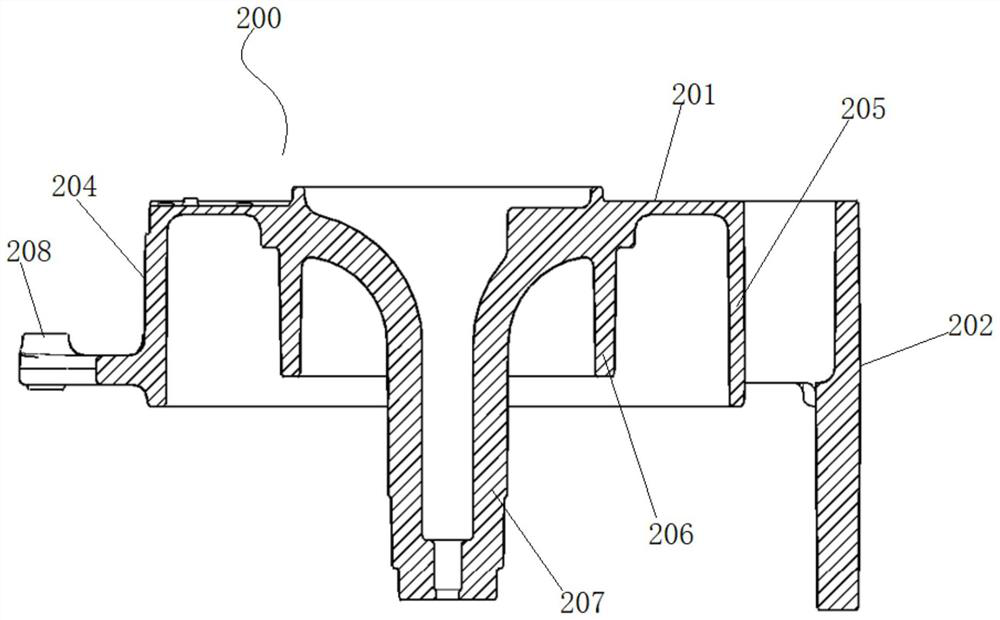

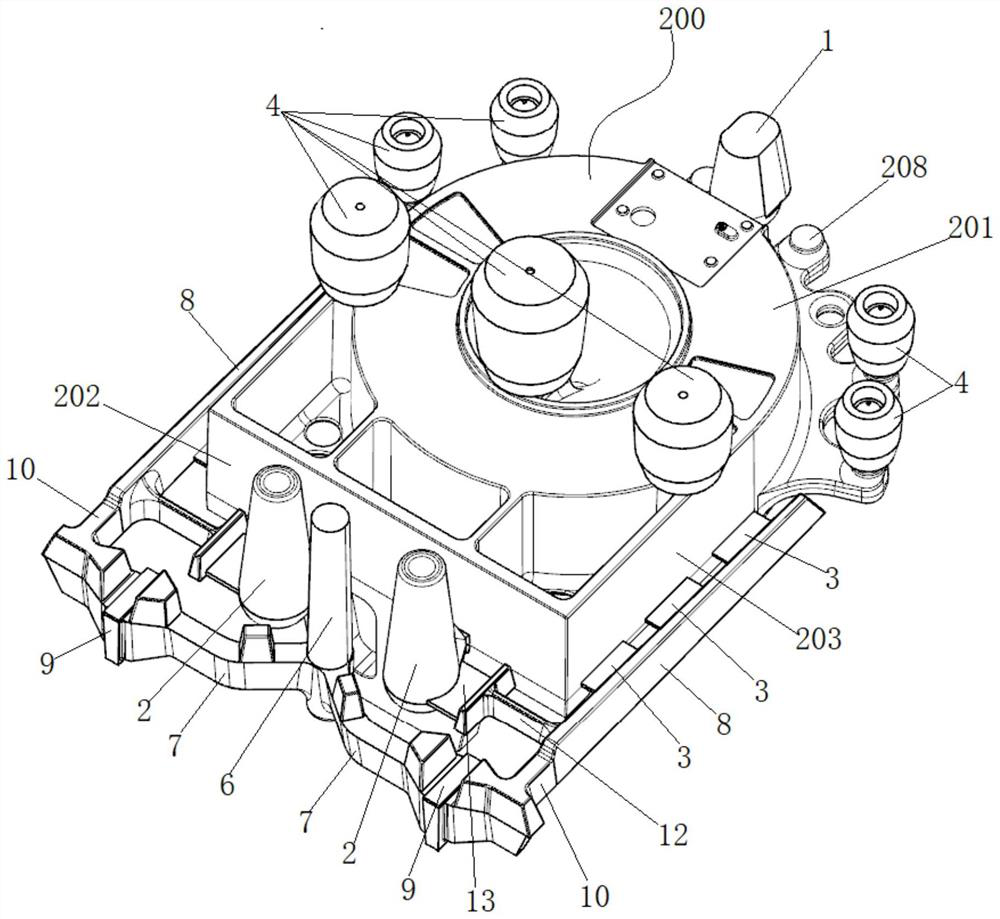

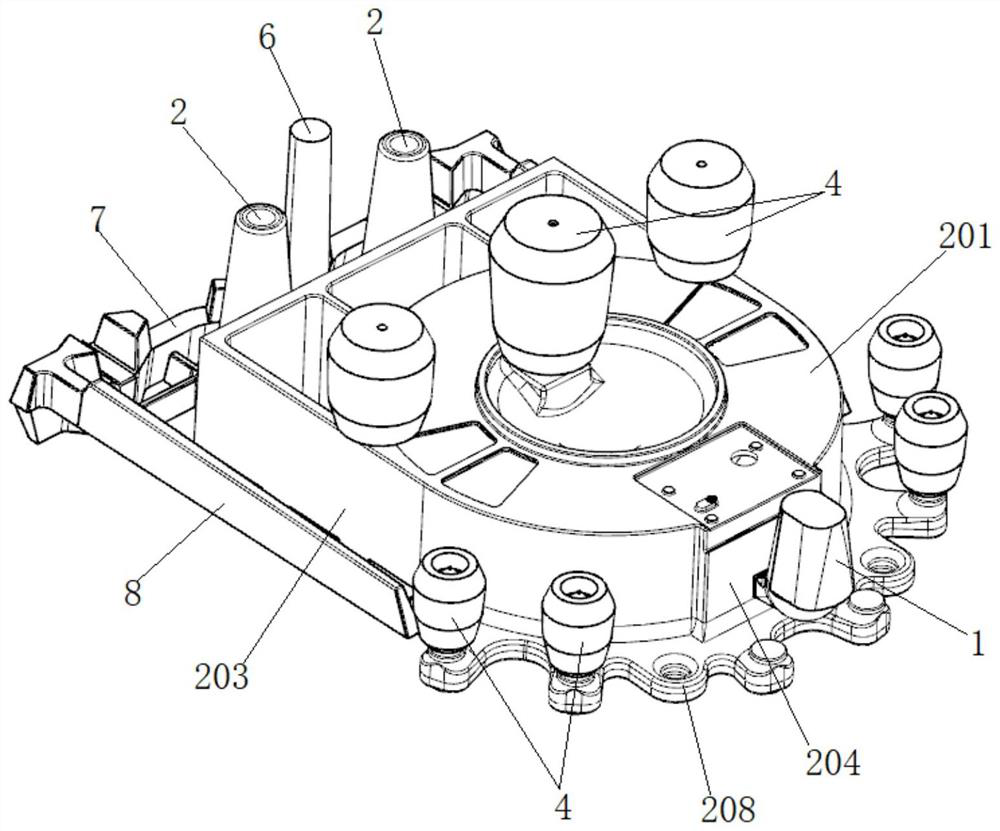

[0028] Please refer to Figure 1-Figure 5 In this embodiment, the high-strength green sand casting system 100 for the oversized traction wheel casing is a sand mold for casting the traction wheel casing 200. The traction wheel casing 200 has an upper plate surface 201, a front The side plate face 202, the symmetrically arranged left and right side plate faces 203 and the rear side plate face 204, the traction wheel casing 200 extends downward from the upper plate face 201 to form a thin-walled ring shell 205 coaxially distributed from outside to inside, The thin-walled annular inner shell 206 and the central axis cylinder 207 , the bottoms of the front side plate surface 201 and the central axis cylinder 207 protrude from the bottom of the thin-walle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com