Method for regenerating SCR (Selective Catalytic Reduction) denitration catalyst by on-line semi-dry method

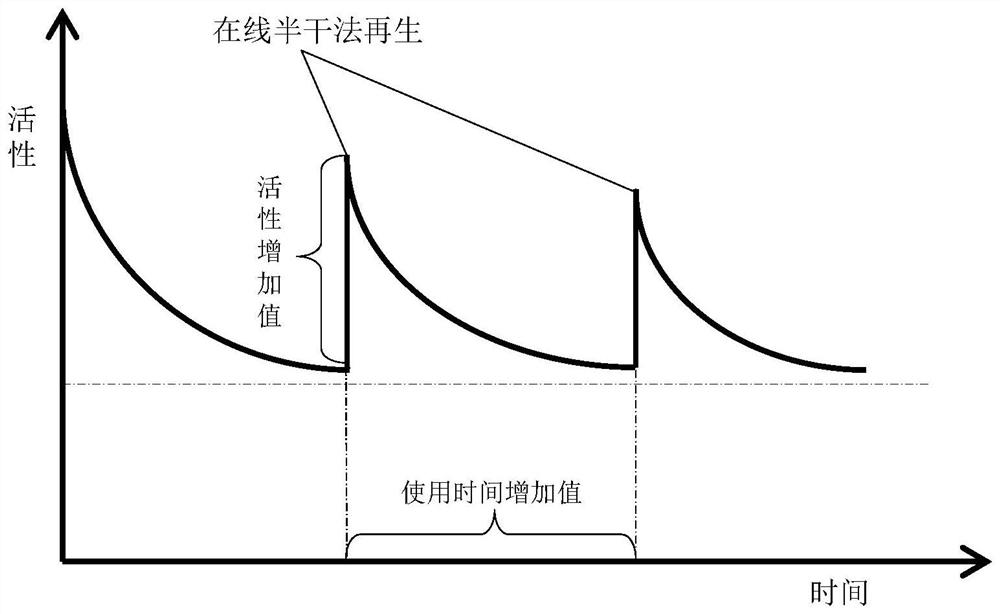

A denitration catalyst, semi-dry technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of long construction period, high consumption of raw materials, high regeneration cost, and achieve extended life, obvious environmental benefits, The effect of suppressing conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

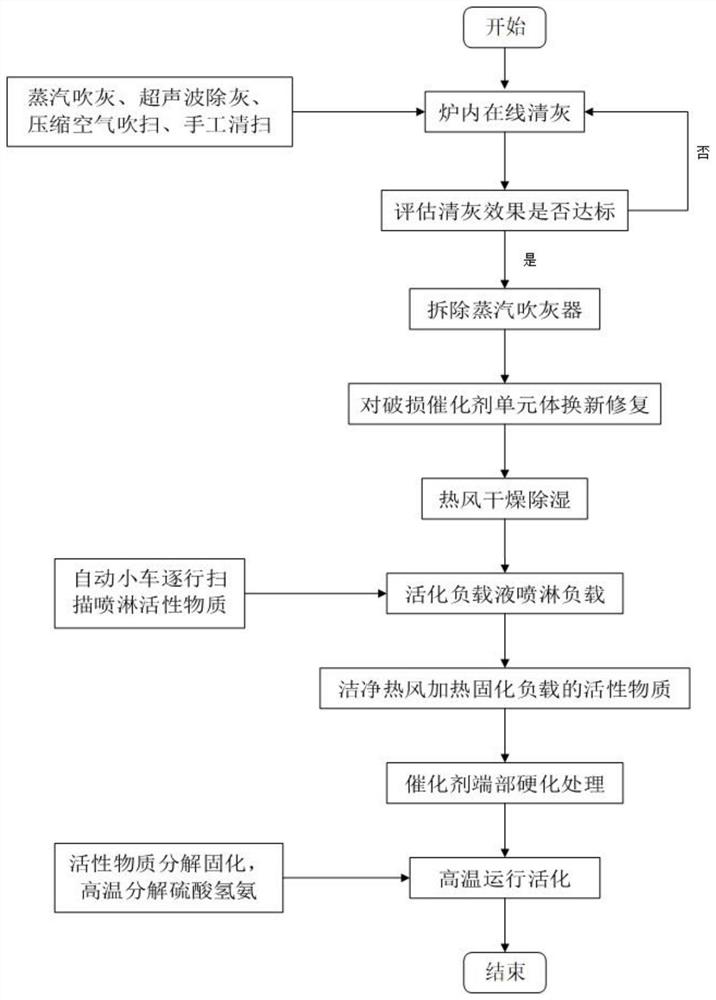

Method used

Image

Examples

Embodiment 1

[0052] The catalyst in the SCR denitrification device of a 300MW coal-fired unit adopts a "2+1" layer arrangement, and two layers of 18-hole catalyst are initially installed. The length of the catalyst is 800mm, and the volume of the catalyst in the initial layer is 280m 3 . The soot blower is a combination of rake steam soot blower and sonic soot blower. After 32,000 hours of operation, the catalyst activity of the initial layer dropped from the initial 39.1m / h to 26.3m / h. After a comprehensive evaluation, the on-line semi-dry method is used to regenerate the catalyst, including the following steps:

[0053] Before shutting down, use the existing rake steam soot blower to carry out continuous blowing for 90 minutes, and the blowing pressure is 1.8 MPa; after stopping, use the sonic soot blower to blow soot for 12 hours. Fly ash away. After the sootblower is out of service, open the manhole door and the hoisting door, remove the steam sootblower and its auxiliary pipelines, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com