Device and method for resin plugging hole of double-sided back-drilled printed circuit board

A technology for printed circuit boards and resin plug holes, which is used in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of resin plug holes, difficult to fill and fill, etc., and achieves the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

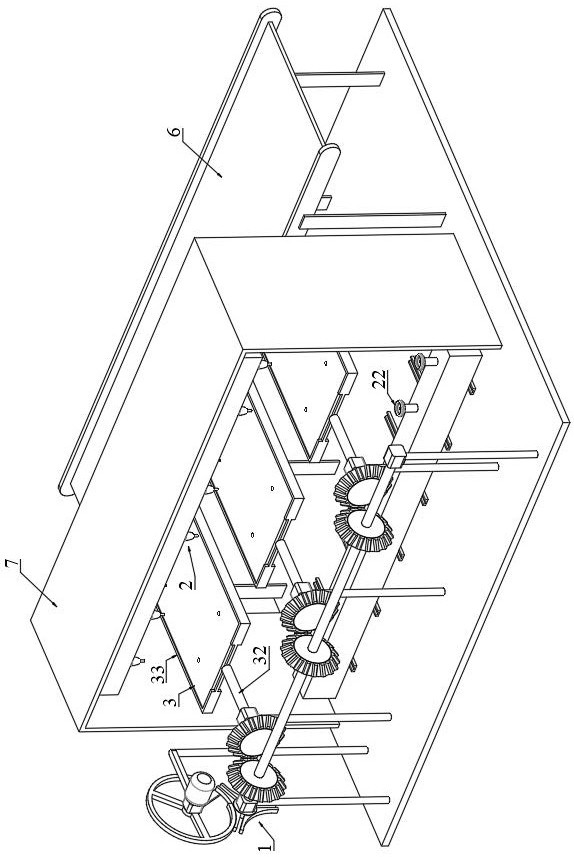

Method used

Image

Examples

Embodiment 2

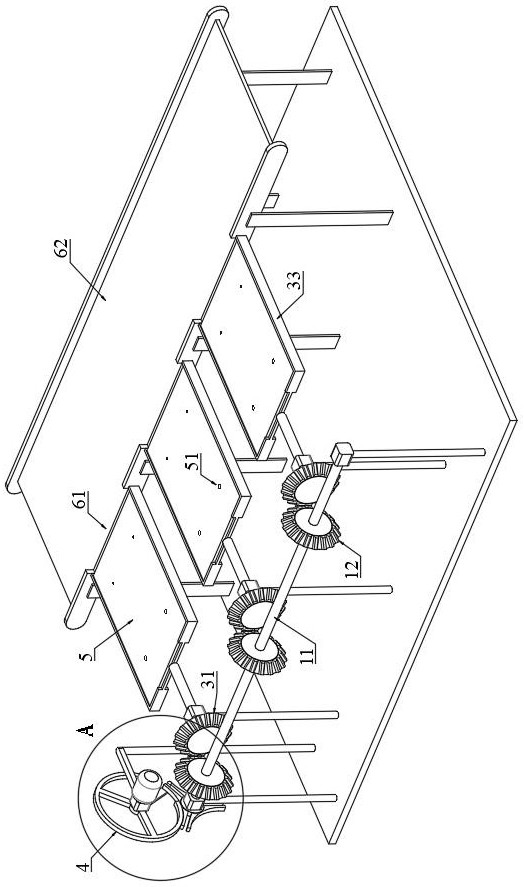

[0051] As shown in FIG. 8, the present embodiment provides a double-sided back-drilling printed circuit board resin plugging method, using the embodiment

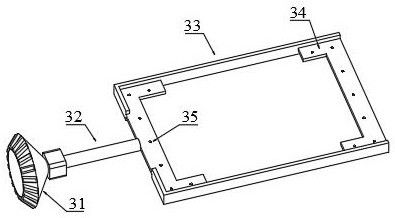

[0054] The printed circuit board 5 is placed in the card slot 34 with the top facing upwards;

[0056] The grease injection pipe head 211 of the resin injection assembly 21 is lowered to a suitable position, and the resin is injected into the first back hole 5-1.

[0059] At the beginning, the runner 42 is rotated and matched with one of the arc-shaped plates 432, so the guide plate 43 will not rotate;

[0064] Like the first resin plug hole, the grease injection pipe head 211 of the resin injection assembly 21 is lowered to a suitable position, and the resin

[0067] The vacuum suction hole 35 stops suction, and the printed circuit board 5 can be pushed from the card slot 34 to the through slot 61 by using the push assembly,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com