Resin hole plugging device and method for double-sided back drilling printed circuit board

A technology for printed circuit boards and resin plug holes, which is applied in the fields of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of resin plug holes, such as holes and difficult filling, and achieve the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

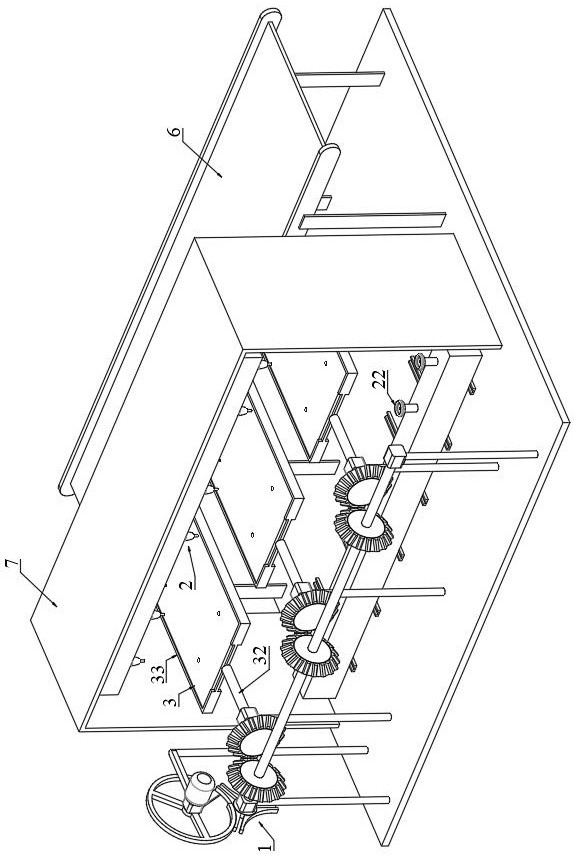

Image

Examples

Embodiment 2

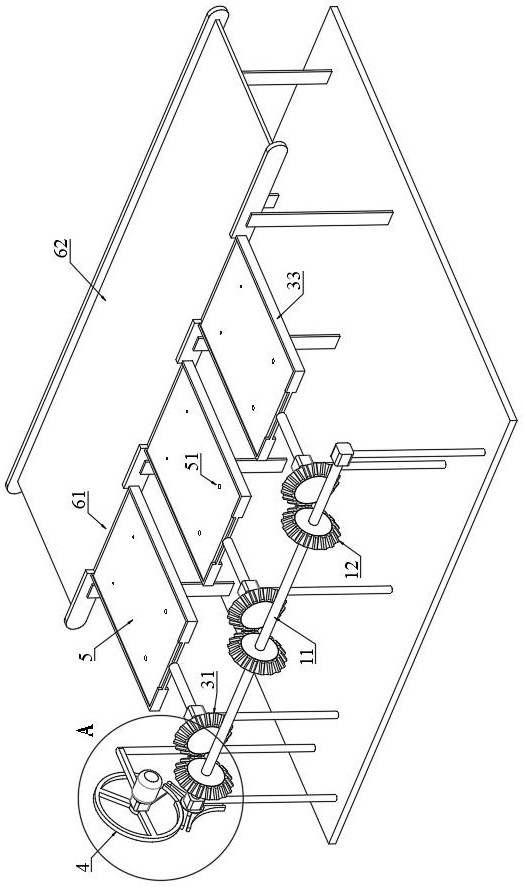

[0051] like Figure 8 As shown, this embodiment provides a double-sided back-drilling printed circuit board resin plugging method, using the double-sided back-drilled printed circuit board resin plugging device in Example 1, including the following steps:

[0052] S1, back drilling: double-sided back drilling of the printed circuit board 5, respectively the first back drilling 5-1 on the top surface and the second back drilling 5-2 on the bottom surface, the first back drilling 5- 1. The inner diameter is first large and then small, and the second back drilling 5-2. The inner diameter is small first and then large;

[0053] S2, the first resin plug hole:

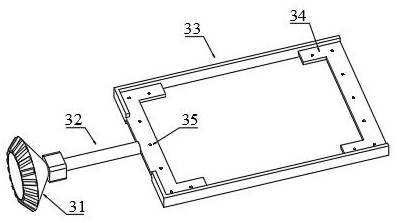

[0054] Place the printed circuit board 5 in the slot 34 with the top facing up;

[0055] Utilize the vacuum adsorption hole 35 to adsorb and fix the printed circuit board 5;

[0056] The grease injection pipe head 211 of the resin injection assembly 21 is lowered to a suitable position, and the resin is injected into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com