Bottom material stir-frying waste heat recovery device

A waste heat recovery device and bottom material technology, which is applied in heat exchangers, heating methods, household heating, etc., can solve the problems of waste heat waste and poor cooling effect, so as to improve heat absorption efficiency, save processing time, increase The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

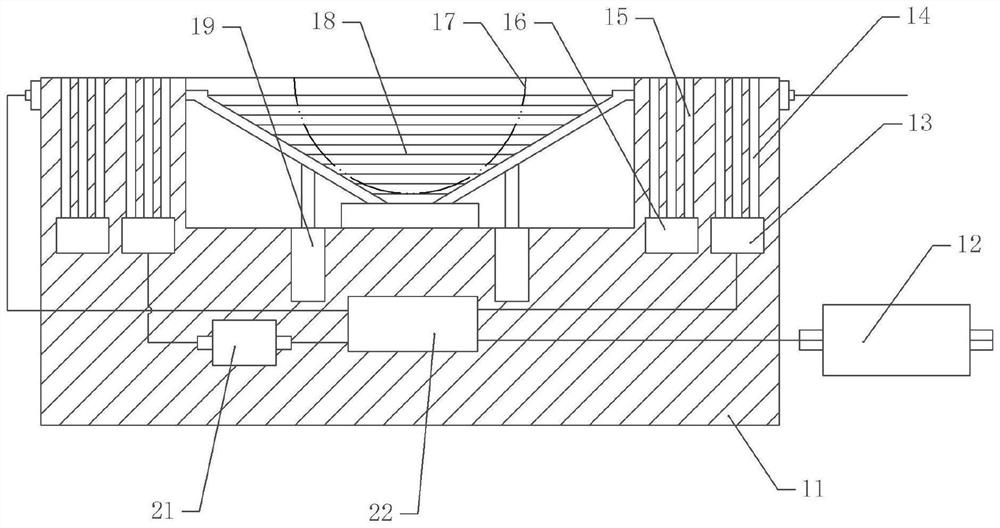

[0038] Basic as attached figure 1 And attached figure 2 As shown, a bottom material frying waste heat recovery device includes a base body 11 and a pot bracket 18 installed on the base body 11. The pot bracket 18 includes a support tube 34 arranged in a V shape. As for the annular pipe, several annular pipes are evenly distributed vertically along the bracket pipe 34, and the diameters of the several annular pipes decrease successively from top to bottom. The annular tube comprises a first arc tube 32 and a second arc tube 33, the two ends of the first arc tube 32 and the second arc tube 33 are all communicated with the bracket tube 34, and both sides of the bracket tube 34 are fixedly connected with The support pipe 31 is fixedly connected with a joint 35 for connecting a water pipe, and the support pipe 31 is vertically slidably matched with the seat body 11 .

[0039] In this embodiment, the support pipe 31 on the left side of the seat body 11 is connected to the waterwa...

Embodiment 2

[0048] The difference between embodiment two and embodiment one is that, as attached image 3 And attached Figure 4 As shown, a drying layer 41 is fixedly installed in the cold air chamber 13. In this embodiment, the drying layer 41 includes a sponge layer 411 and condensation sheets 414 bonded and fixed on both sides of the sponge layer 411. The condensation sheets 414 are made of iron materials, and the condensation A hollow support part 412 is fixedly connected to the sheet 414 by screws, the sponge layer 411 extends into the support part 412, and the support part 412 is filled with a desiccant 413, which is quicklime.

[0049] The specific implementation process is as follows:

[0050] Since the hot air passes through the cold water in the water chamber 22 and turns into cold gas, the water content in the cold gas will be higher and the temperature of the cold gas will be lower than that of the hot air. When the cold gas encounters an item with a lower temperature , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com