Cooling equipment for industrial filtering membrane production

A technology of cooling equipment and filter membrane, which is applied in household refrigeration equipment, lighting and heating equipment, applications, etc., can solve the problems of high energy consumption and low wind utilization rate, and achieve increased cooling efficiency, high utilization rate, and strong pertinence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is a specific embodiment of the present invention and a further description of the technical solutions of the present invention in connection with the accompanying drawings, but the present invention is not limited to these embodiments.

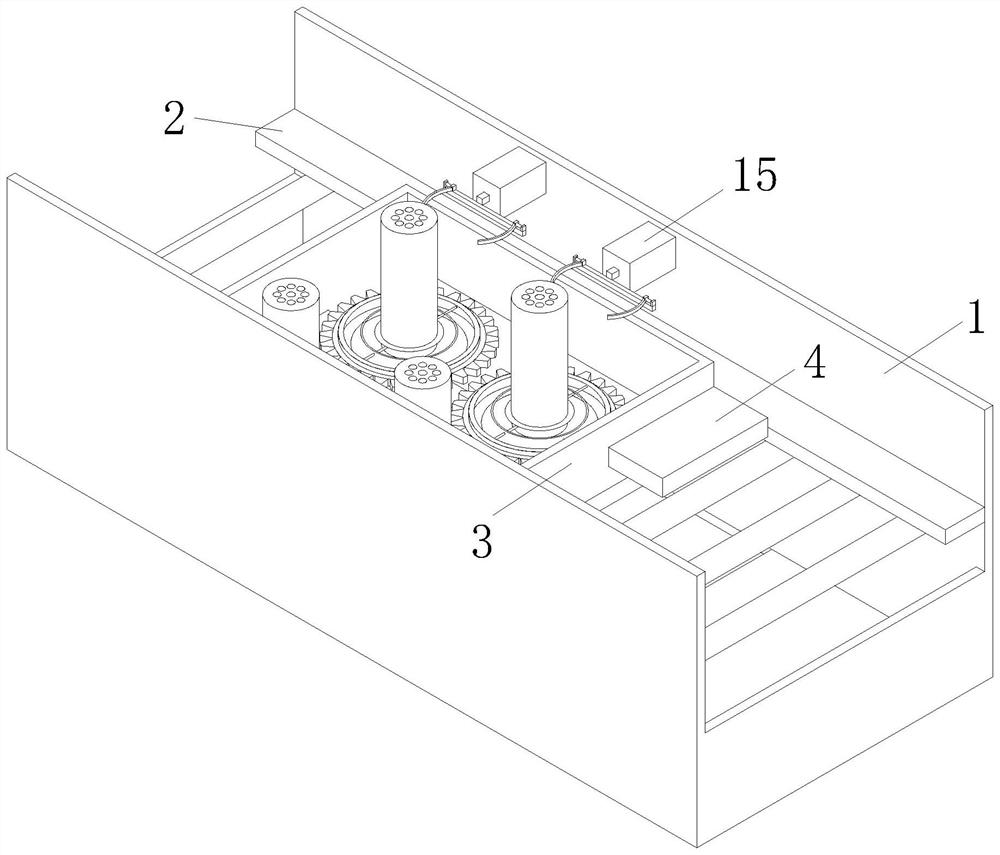

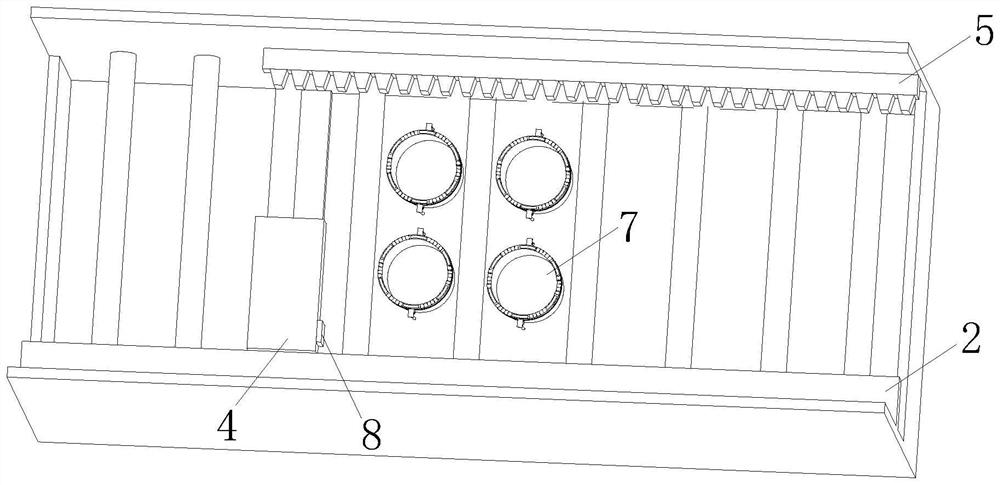

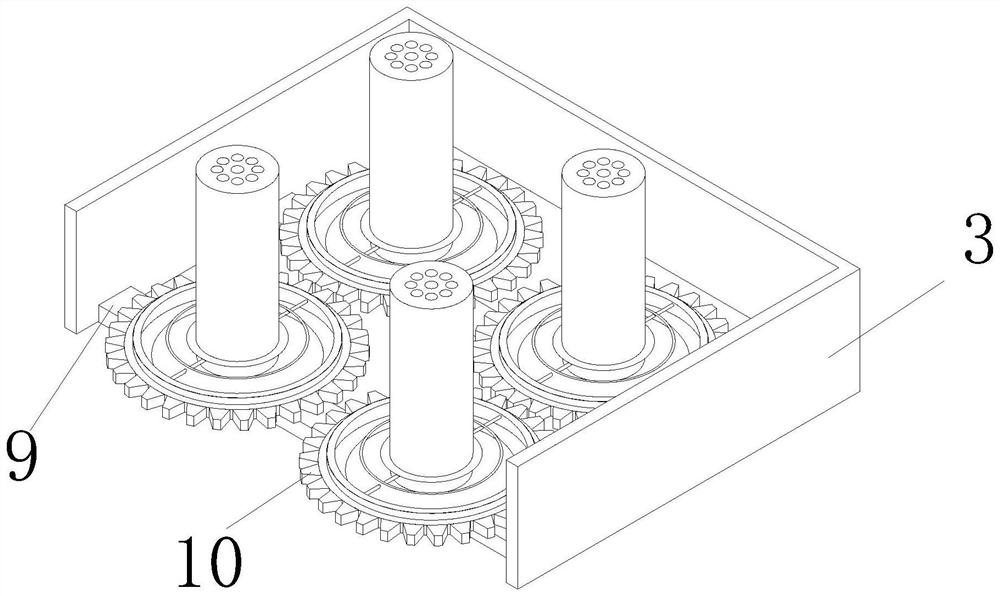

[0043] Such as Figure 1 - Figure 9 As shown, the industrial filter membrane production cooling equipment, including the cooling chamber 1, and the cooling chamber 1 is rotated and connected to the transmission roller, and the inner wall of the cooling chamber 1 is fixed to the finished strip 2, and the inner wall of the cooling chamber 1 is fixed. Both the rack 5, the limit strip 2 and the rack 5 are located above the drive roller, and there is also a casing 3 on the drive roller, and the casing 3 is provided with two rows of flow in the longitudinal direction of the rack 5, and the casing 3. On the side of the restricted strip 2, there is a tooth ring 10 outside, and the air blower is provided below the flow of the flow. twe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com