Efficient blowpipe silencer

A muffler, a high-efficiency technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., to prevent sound from being transmitted outwards, improve muffler exhaust, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

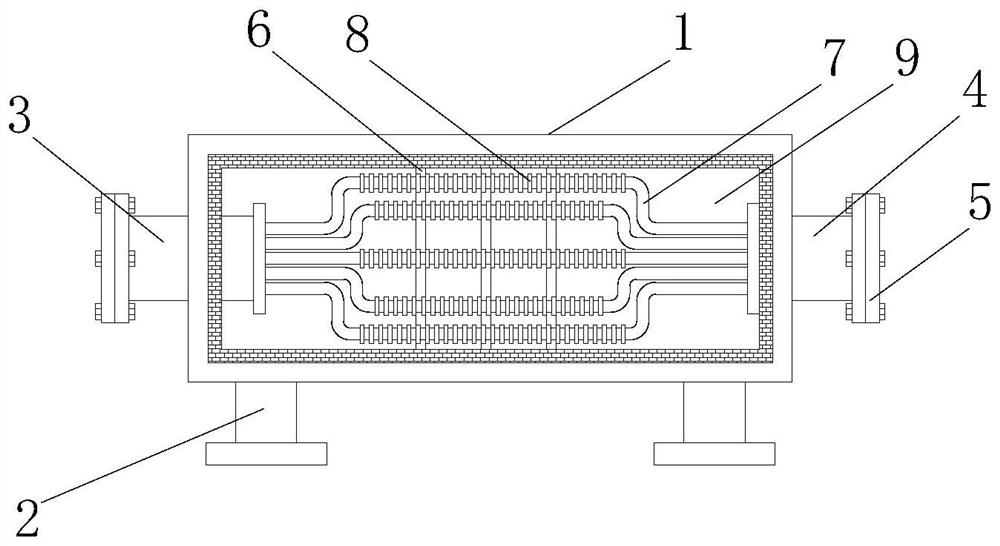

[0022] like figure 1 As shown, a high-efficiency blowpipe muffler includes a housing 1, one end of the housing 1 is connected with an air inlet pipe 3, the other end is connected with an air outlet pipe 4, and a plurality of muffler pipes 7 and a plurality of stoppers 6 are arranged inside. , the two ends of the muffler branch pipe 7 pass through the limit piece 6 respectively, and connect the air intake pipe 3 and the air outlet pipe 4 through the connecting rod 9, the described muffler branch pipe 7 is in a bent structure, and the stop piece 6 is fixed On the housing 1 , the muffler is connected to the external air-filling equipment through the flange 5 .

[0023] A bracket 2 is fixed on the bottom of the housing 1, and the bracket fixes the blowpipe muffler to the device.

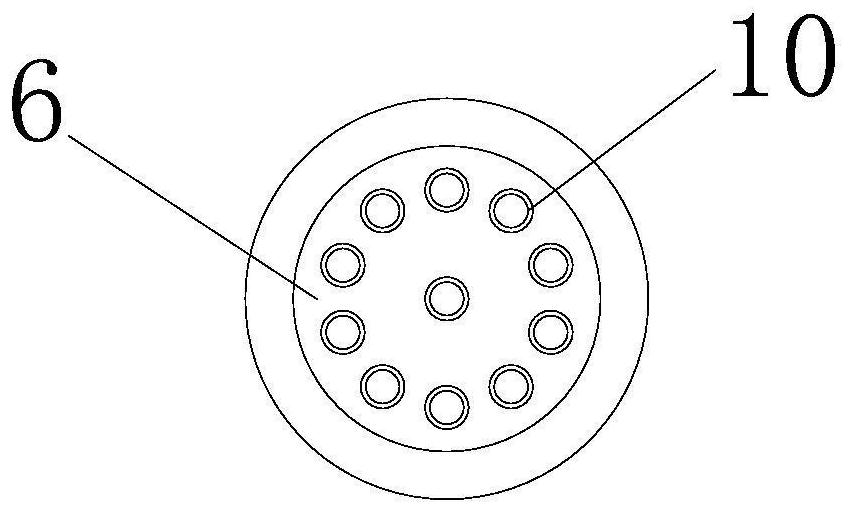

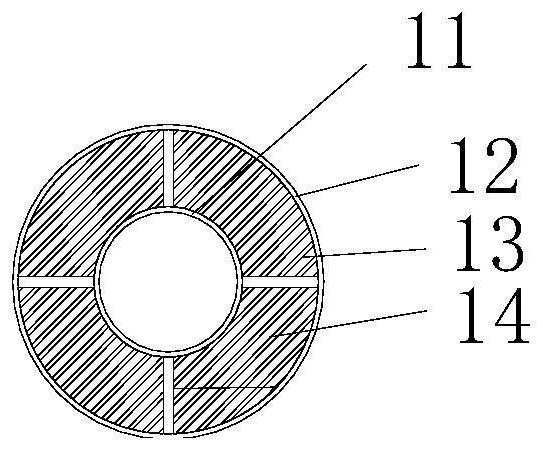

[0024] A damping ring 10 is provided at the joint between the limiting piece 6 and the muffler branch pipe 7, such as figure 2 As shown, the shock absorbing ring 10 is internally fastened to the surfa...

Embodiment 2

[0031] A high-efficiency blowpipe muffler, comprising a shell 1, one end of the shell 1 is connected with an air inlet pipe 3, the other end is connected with an air outlet pipe 4, and a plurality of muffler pipes 7 and a plurality of stoppers 6 are arranged inside. The two ends of the muffler pipe 7 pass through the stopper 6 respectively, and connect the inlet pipe 3 and the outlet pipe 4 through the connecting rod 9. The muffler pipe 7 has a bent structure, and the stopper 6 is fixed on the shell 1, the muffler is connected to the external air-filling equipment through the flange 5.

[0032] A bracket 2 is fixed on the bottom of the housing 1, and the bracket fixes the blowpipe muffler to the device.

[0033] A damping ring 10 is provided at the joint between the limiting piece 6 and the noise-absorbing branch pipe 7, and the inside of the shock-absorbing ring 10 is fastened on the surface of the noise-absorbing branch pipe 7, and the limiting piece is connected externally,...

Embodiment 3

[0040] A high-efficiency blowpipe muffler, comprising a shell 1, one end of the shell 1 is connected with an air inlet pipe 3, the other end is connected with an air outlet pipe 4, and a plurality of muffler pipes 7 and a plurality of stoppers 6 are arranged inside. The two ends of the muffler pipe 7 pass through the stopper 6 respectively, and connect the inlet pipe 3 and the outlet pipe 4 through the connecting rod 9. The muffler pipe 7 has a bent structure, and the stopper 6 is fixed on the shell 1, the muffler is connected to the external air-filling equipment through the flange 5.

[0041] A bracket 2 is fixed on the bottom of the housing 1, and the bracket fixes the blowpipe muffler to the device.

[0042] A damping ring 10 is provided at the joint between the limiting piece 6 and the noise-absorbing branch pipe 7, and the inside of the shock-absorbing ring 10 is fastened on the surface of the noise-absorbing branch pipe 7, and the limiting piece is connected externally,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com