Construction structure and construction method for shield tunneling machine to penetrate through existing shield tunnel in close range

A technology for shield tunnels and existing tunnels, which is applied to tunnels, earthwork drilling, mining equipment, etc., and can solve the problem of difficulty in achieving uniform grouting across the entire section, the limited number of grouting holes reserved for pipe rings, and increasing the size of existing tunnels. Problems such as floating and deformation of the tunnel can save manpower and machine investment, reduce soil disturbance, and avoid hard contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

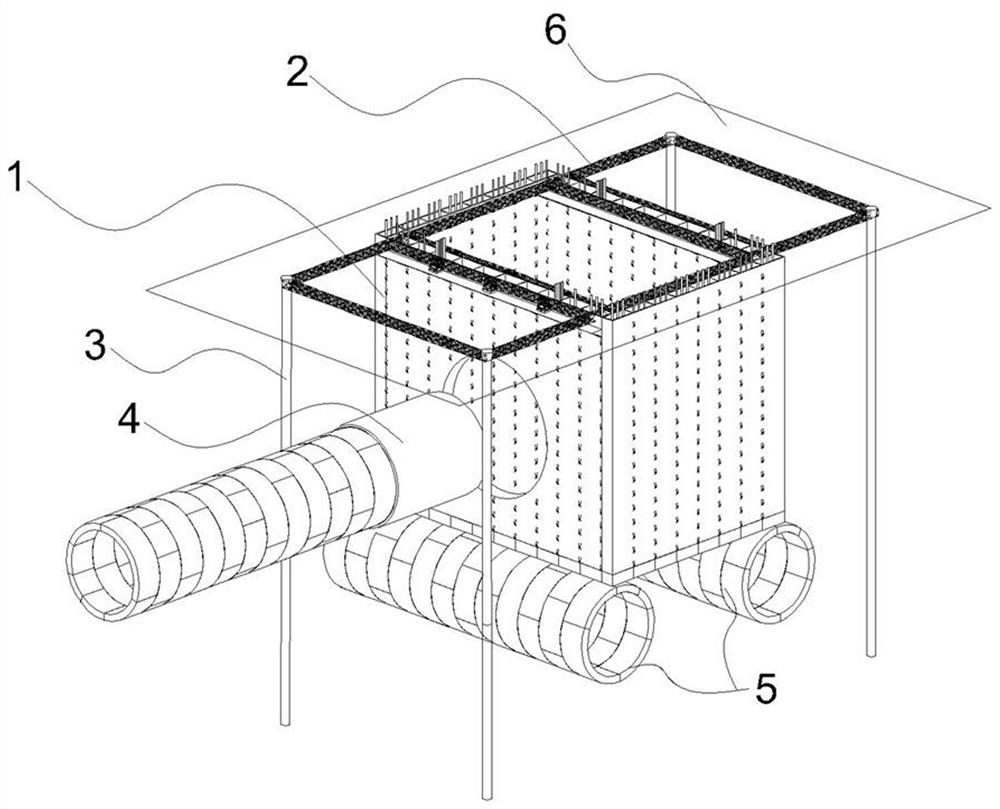

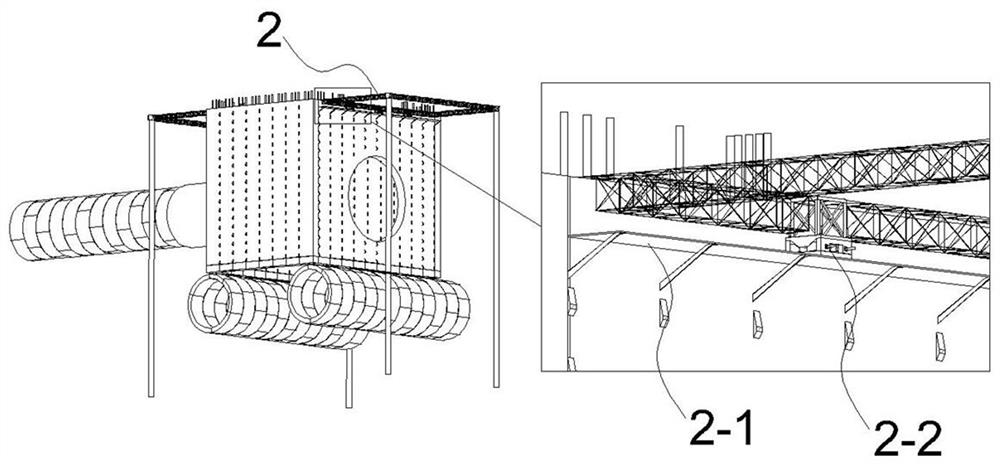

[0053] A construction structure for a shield tunnel passing through an existing shield tunnel at a short distance, including an anti-floating well 1, a ground beam system 2, a pile foundation 3 and other components. Such as figure 1 As shown, the existing shield tunnel 5 located underground extends horizontally, and the newly constructed shield tunnel needs to pass above the existing shield tunnel 5 and extend longitudinally.

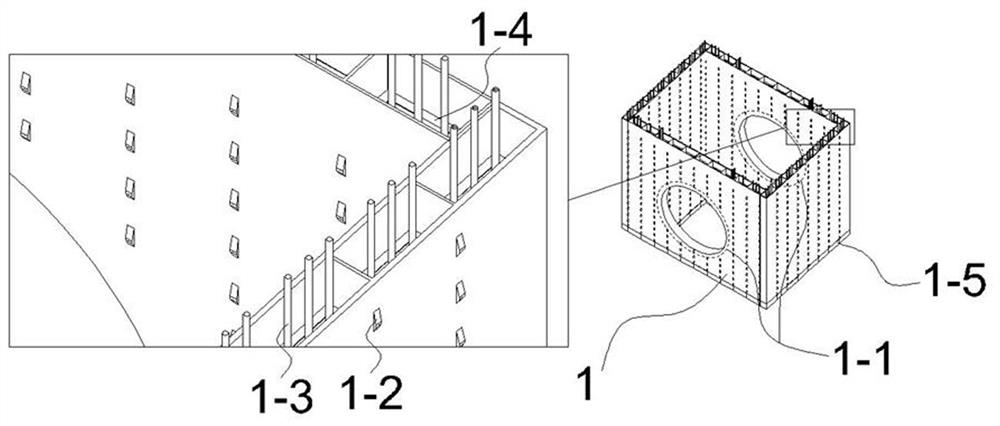

[0054] The anti-floating-sinking well 1 is a sub-compartment steel caisson structure, and the interior can be filled with concrete as required to ensure that the weight of the anti-floating-sinking well is basically the same as that of the replaced soil. Gas niches 1-2 are arranged on the outer panels of each warehouse of the anti-floating and sinking well 1. The gas niches 1-2 are in the form adopted by conventional caissons, and the arrangement of high-pressure gas pipelines used in conjunction with the gas niches 1-2 is no longer shown in the figure....

Embodiment 2

[0065] In this embodiment, the construction of anti-floating and sinking well 1 is the same as the conventional air curtain caisson method. Since the air curtain method sinking generally meets the construction requirements, the mud suction pipe can be used as a supplementary measure.

[0066] On the basis of Embodiment 1, the present embodiment installs a multifunctional blade foot structure 1-5 at the bottom of the anti-floating well 1, and the multifunctional blade foot structure 1-5 consists of multiple blade feet, rubber blocks and multiple Working tube 1-3 is composed.

[0067] The plurality of blade feet include a first blade foot 1-5-1 and a second blade foot, and the first blade foot 1-5-1 and the second blade foot are each provided with a frustum-shaped concave cavity with an opening downward , the frustum-shaped concave cavity is wide at the bottom and narrow at the top, and is a concave cavity that gradually expands downward. The top plate of the concave cavity is ...

Embodiment 3

[0080] In the case of poor geological conditions, it is expected that the shield machine 4 will generate a large disturbance after tunneling.

[0081] Therefore, on the basis of the second embodiment, this embodiment adds a working tube for grouting. The grouting pipe is connected to the second blade foot, and after the anti-floating and sinking well 1 is in place, the grouting pipe is used for grouting to form an improved soil mass under the caisson. The stiffness and strength of the improved soil are improved, and the integrity is stronger, and better anti-floating effect can be obtained after the tunneling of the shield machine 4 passes.

[0082] The grouting pipe can be installed separately, or can be made into a composite pipe with the dredge pipe, sharing the main conveying pipeline, so as to simplify the construction process and reduce the construction cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com