Method and device for preparing in-situ sand and gravel seepage-proofing material and constructing water interception curtain

A technology of anti-seepage materials and preparation devices, which is applied in the direction of clay preparation devices, cement mixing devices, chemical instruments and methods, etc., and can solve the problems of the decrease in strength and impermeability of anti-seepage concrete, the difficulty of safety prevention and control, and the low utilization rate of the site and other issues to achieve the effect of reducing material costs, shortening transportation time, and avoiding land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Step 1: Determine the position of the water-cutting curtain 8 according to the engineering geology and hydrogeological characteristics of the open-pit coal mine.

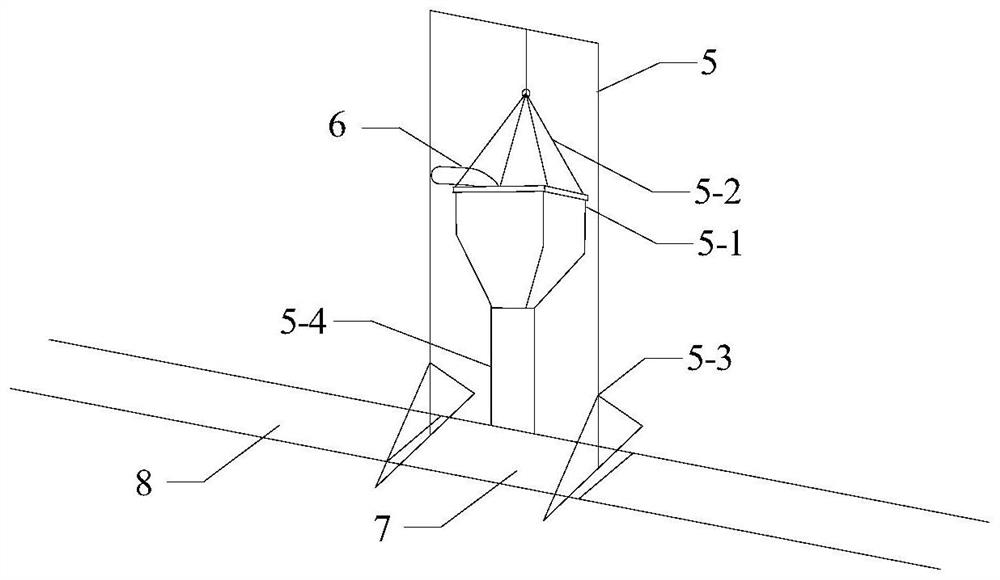

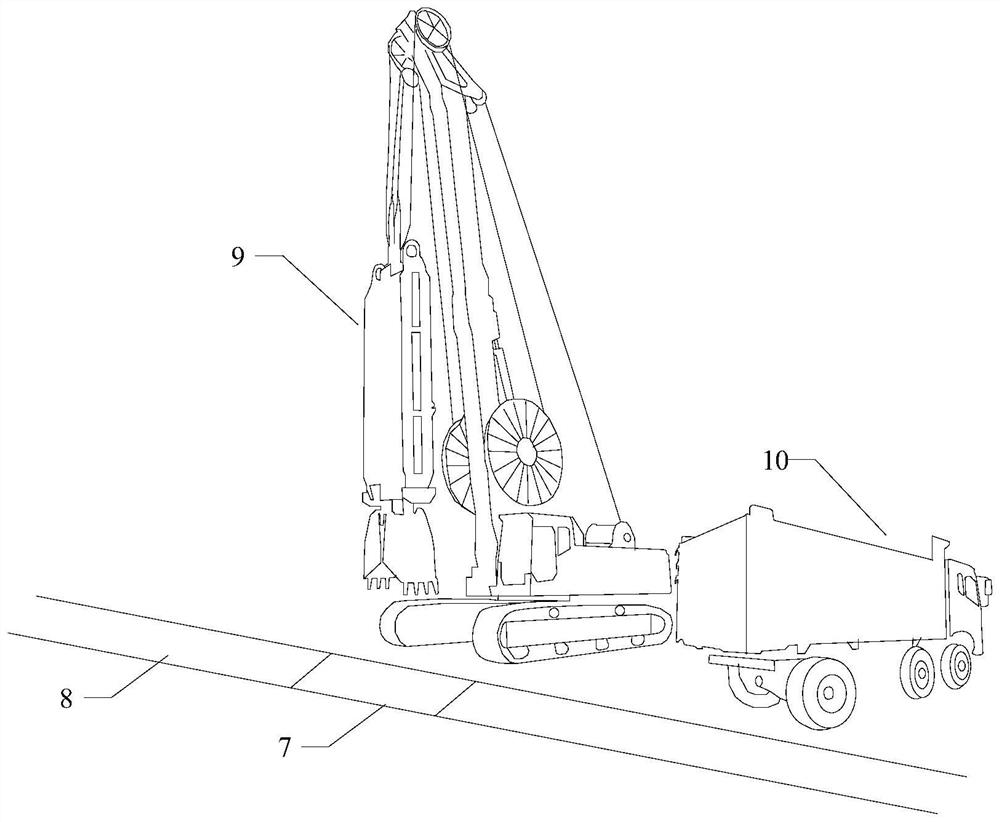

[0065] Step 2: Use the trough forming equipment 9 to excavate the 600mm width cut-off curtain 8 trough section, the excavation depth is not less than 2m when entering the water-resistant stratum 12, and lift the stratum 11 materials such as natural sand, pebbles, gravels, etc. in the trough section to the ground Inside the transport device 10.

[0066] Step 3: Inject bentonite mud into the excavated trough section to protect the wall, maintain the upright stability of the trough section, and avoid stratum collapse in the trough.

[0067]Step 4: The natural sand, pebbles, gravels and other formation 11 materials excavated in the tank section are transferred to the aggregate preparation device 1 by the transport vehicle 10 .

[0068] Step 5: Repeat steps 2 to 4 until a cut-off curtain groove section is excavat...

Embodiment 2

[0078] Step 1: Determine the position of the water interception curtain 8 according to the characteristics of the pollutant diffusion prevention and control project. The bottom of the water interception curtain 8 is generally located in the aquifer, and the pollutant diffusion area is trapped inside the water interception curtain.

[0079] Step 2: Use the trough forming equipment 9 to excavate the 800mm width cut-off curtain 8 trough section, and lift the natural sand, pebbles, gravel and other formation materials in the trough section to the ground transportation equipment 10 .

[0080] Step 3: Inject mud into the excavated trough section to protect the wall, maintain the stability of the trough section, and avoid the stratum stratum collapse in the trough.

[0081] Step 4: The natural sand, pebbles, gravels and other formation materials excavated in the tank section are transferred to the aggregate preparation device 1 by the transport vehicle 10 .

[0082] Step 5: Repeat st...

Embodiment 3

[0092] Step 1: According to the engineering geology and hydrogeological characteristics of the open-pit coal mine, determine the position of the water-cutting curtain 8. The bottom of the water-cutting curtain 8 is generally located in the water-resisting layer, and the open-pit is trapped inside the water-cutting curtain.

[0093] Step 2: Use the trough forming equipment 9 to excavate the trough section of the water interception curtain 8 with a width of 700 mm, and lift the natural sand, pebbles, gravel and other formation materials in the trough section to the ground transportation equipment 10 .

[0094] Step 3: Inject mud into the excavated trough section to protect the wall, maintain the upright stability of the trough section, and avoid stratum strata collapse in the trough.

[0095] Step 4: The natural sand, pebbles, gravels and other formation 11 materials excavated in the tank section are transferred to the aggregate preparation device 1 by the transport vehicle 10 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com