Glass aligning and laminating device for capacitive touch screen production

A technology of capacitive touch screen and bonding device, which is applied in lamination devices, layered products, cleaning methods using tools, etc., can solve problems such as low efficiency, inapplicability to mass production, and insensitive touch screens, etc., to ensure cleanliness , increase production efficiency, and improve the effect of wiping work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

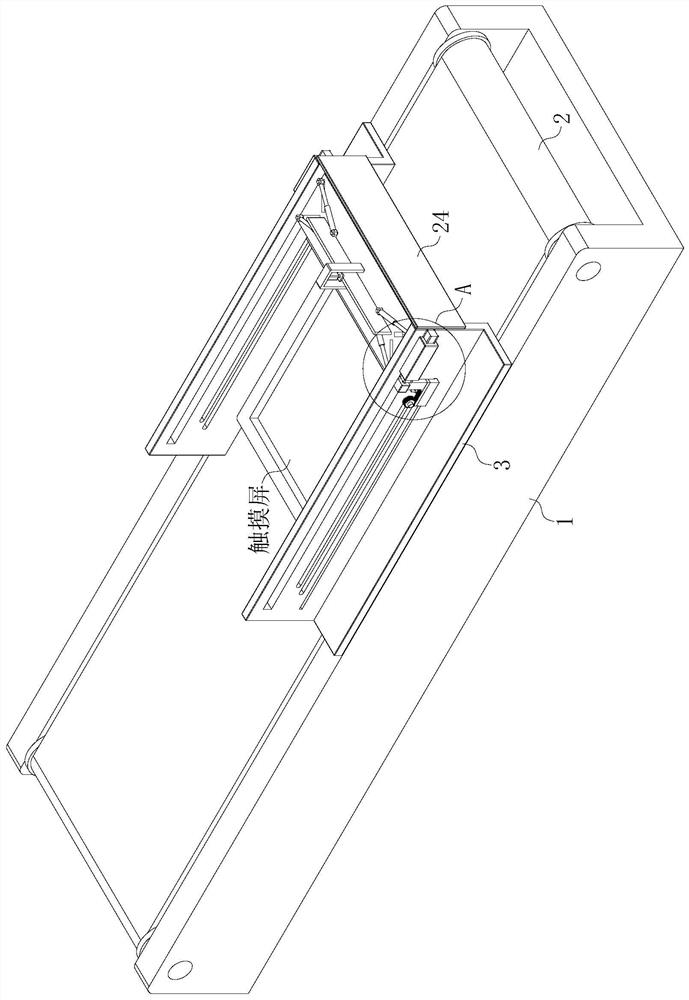

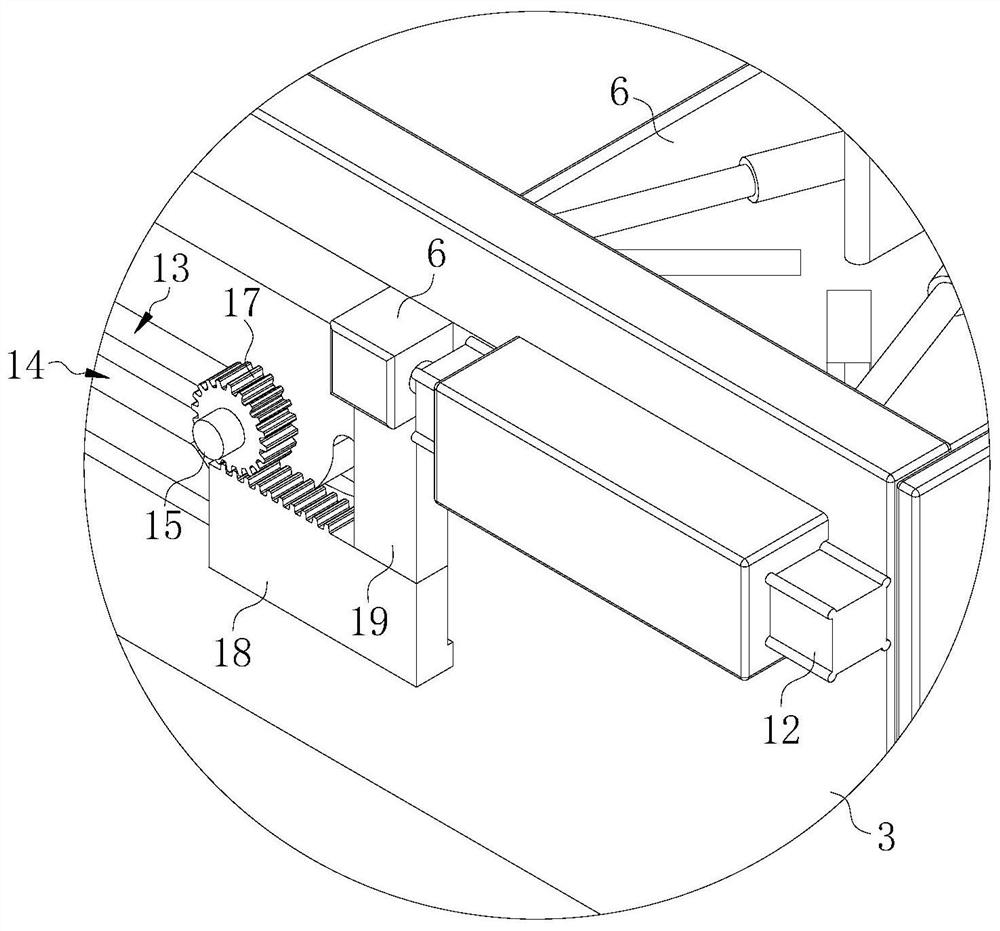

[0029] see Figure 1-10 , the present invention provides a technical solution: a glass alignment and bonding device produced by a capacitive touch screen, including a base plate 1, a belt conveyor 2 is arranged on the base plate 1, and the front and rear sides of the top of the base plate 1 are fixed. A mounting plate 3 is connected, and the two mounting plates 3 are jointly slidably connected with a fixed plate 4 positioned above the belt conveyor 2, and several air blowing pipes 5 are fixedly connected to the fixed plate 4; the two mounting plates 3 Slidingly connected with the first slide plate 6 in the left and right directions together, the first slide plate 6 is rectangular, and the four corners of the bottom of the first slide plate 6 are provided with inclined chute 7 along the diagonal direction, and the inclined chute 7 A splint 8 is slidably connected inside; the top of the splint 8 is rotatably connected to a gas spring 9, and the gas spring 9 is rotatably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com