Finished trouser waist paste production device and finished trouser

A production device and trouser waist technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of inconsistent force, increased manufacturing cost of trousers, and easy sweating, etc., to reduce the stressed area, save production materials, and increase comfort degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

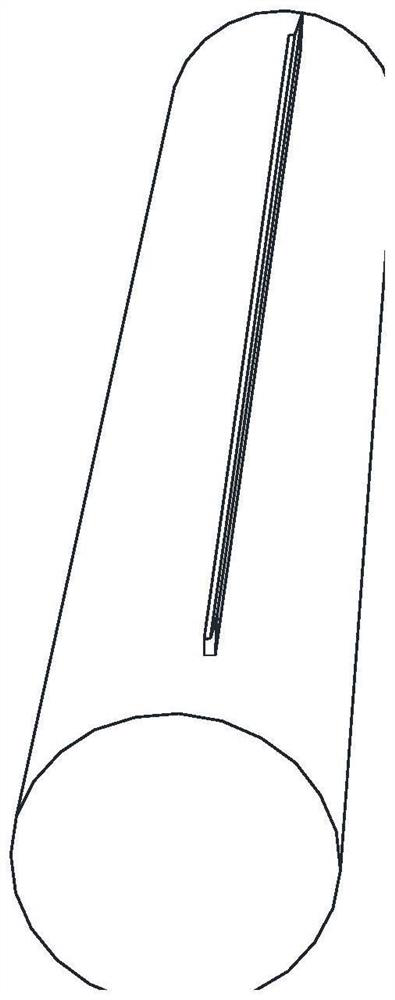

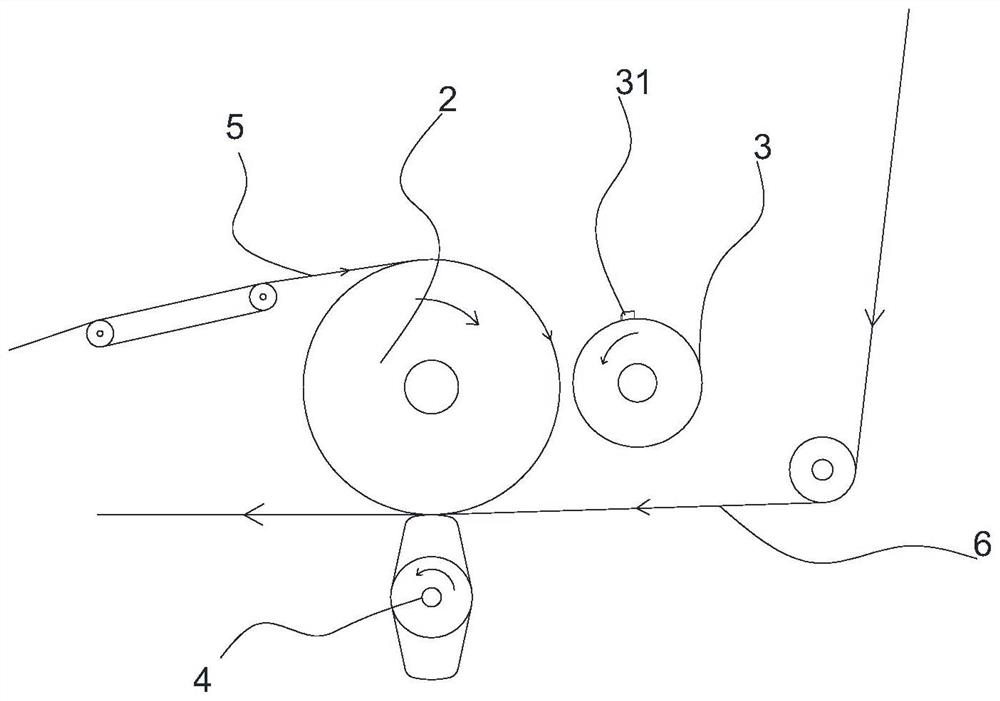

[0042] The utility model relates to a processing device for front waist stickers of finished trousers, which is used for processing the front waist stickers of finished trousers. Including negative pressure roller 2, cutter roller 3, and beating roller 4; the axes of the negative pressure roller 2, cutter roller 3, and beating roller 4 are parallel; in a side view, the three are triangularly distributed. The negative pressure roller 2 is used to absorb the front waist sticker material 5, and interacts with the cutter roller 3 to cut the material; cooperates with the beating roller 4 to reinforce the waist sticker material.

[0043]Cutter roller 3 comprises bottom roller and cutter 31 groups, and described cutter 31 groups comprise two cutters 31; Cutter 31 is arranged on the bottom roller; Described cutter 31 comprises blade, and cutter 31 edge lines are at The elliptical surface forms an angle of 10-20 degrees with the generatrix of the side of the bottom roller. The edge li...

Embodiment 2

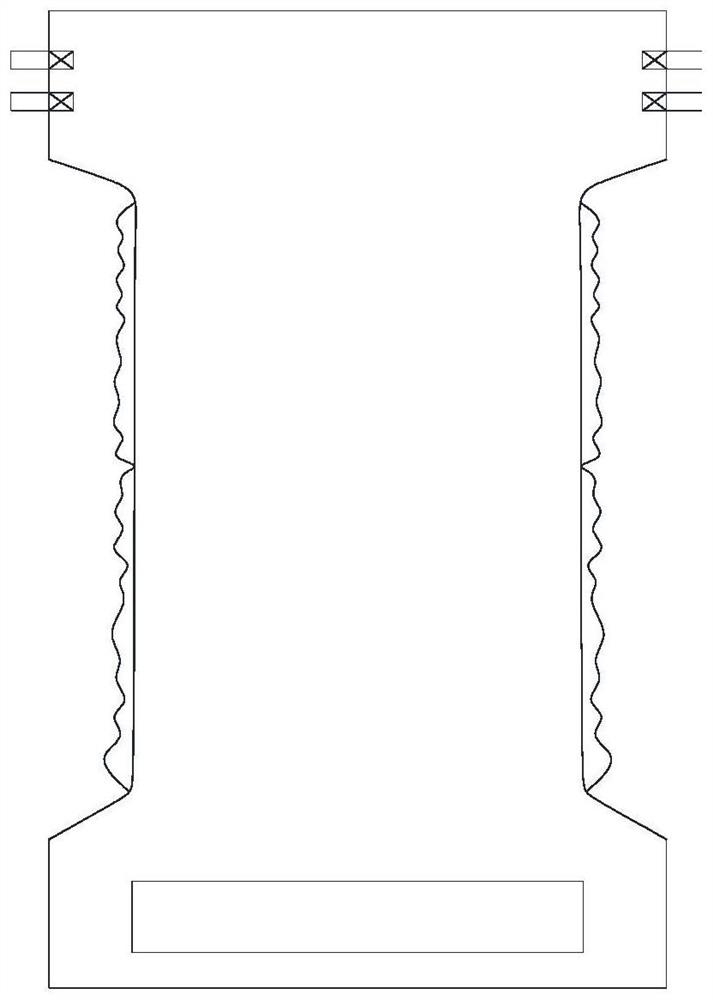

[0052] A kind of trousers, comprising a core body 1, a front waist sticker, and ear stickers; the core body 1 has a front edge 11 and a rear edge 12, and the front waist sticker is bonded to the outer surface of the core body 1 near the front edge 11; the ear stickers and the core body 1 is connected to the side edge of the core 1 near the rear edge 12. The outer surface mentioned in this embodiment refers to the side facing the outside when the trousers are used.

[0053] In other possible embodiments, the core 1 has a front wall and a back wall, the front edge 11 is located on the front wall, and the rear edge 12 is located on the back wall; the waist sticker is pasted on the outer surface of the front wall; edge connection; when in use, the ear stickers are bonded to the front waist stickers, and the front circumference and the back circumference surround the waist to fix the trousers; the front circumference and the rear circumference are equipped with elastic bands, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com