Fuel cell thermal management system and control method thereof

A thermal management system and fuel cell technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problem of increasing the amount of coolant used, complex control systems, affecting the service life of parts and ride comfort, etc. problem, to achieve the effect of reducing the overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

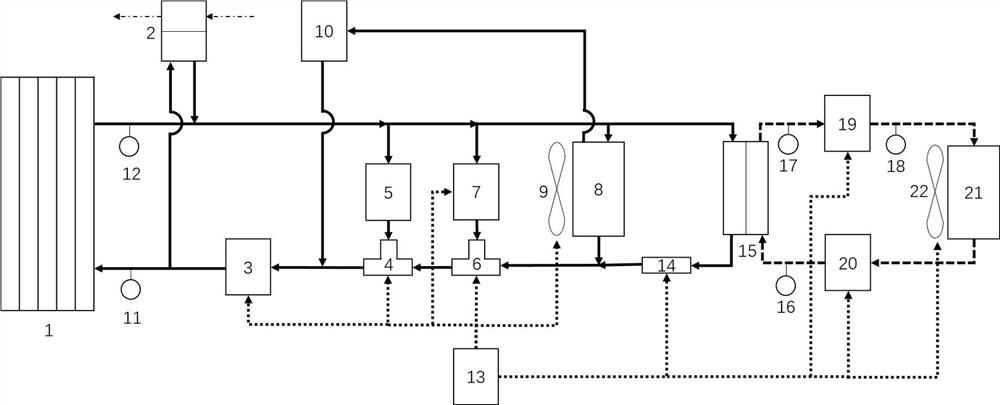

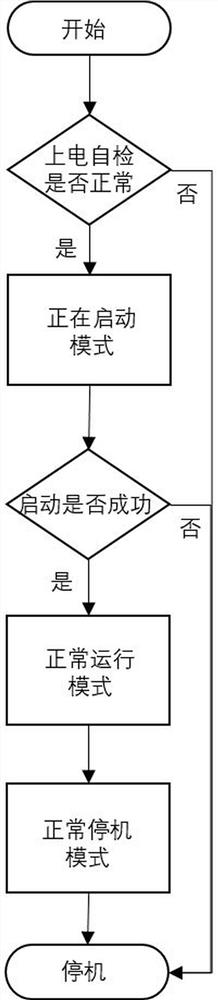

[0045] The following is attached Figure 1-5 The specific implementation manners of the present invention are further described in detail.

[0046] When this embodiment is in use, the circuits include four types: the air circuit of the air system, the cooling liquid circuit of the cooling system, the working medium circuit of the water heating system, and the control signal circuit.

[0047] Heat sources that need to be cooled include electric stacks and air system intercoolers. The air system intercooler is an air circuit on the air system side, and a cooling liquid circuit on the cooling system side.

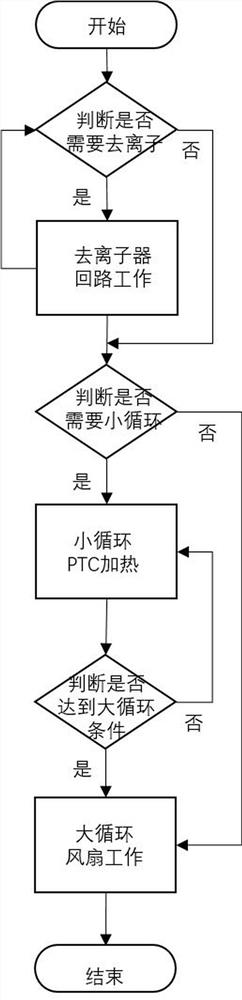

[0048] The small circulation loop includes electric stack, air system intercooler, water pump, electric control tee, thermostat, cooling system PTC.

[0049] The large circulation circuit includes electric stack, air system intercooler, water pump, electric control tee, thermostat, cooling system radiator, cooling system fan.

[0050] The deionizer circuit includes electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com