Preparation process of antireflection film for OLED flexible display

An anti-reflection film, flexible display technology, applied in metal material coating process, sputtering coating, semiconductor/solid-state device manufacturing, etc. and heat shielding effect, high toughness strength, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

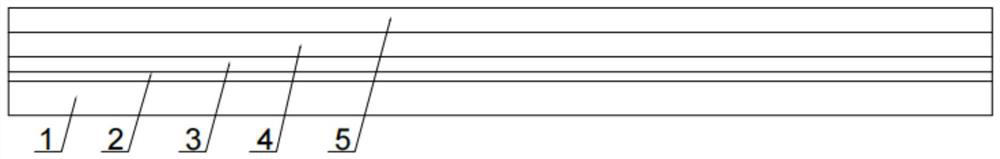

[0045] Such as figure 1 Shown: a kind of OLED flexible display anti-reflection film of the present embodiment, its structure comprises:

[0046] The base film 1, its raw material comprises PMMA and COP, and the thickness of the base film 1 is 756 angstroms;

[0047] Magnesium fluoride substrate 2, which is deposited on the surface of the base film 1, the thickness of the magnesium fluoride substrate 2 is 208 angstroms;

[0048] Aluminum oxide film layer 3, which is deposited on the surface of the magnesium fluoride substrate 2, the thickness of the aluminum oxide film layer 3 is 336 angstroms;

[0049] Hafnium oxide film layer 4, which is deposited on the surface of the aluminum oxide film layer 3, the thickness of the hafnium oxide film layer 4 is 540 angstroms;

[0050] Silicon dioxide film layer 5, which is deposited on the surface of the hafnium oxide film layer 4, and the thickness of the silicon dioxide film layer 5 is 545 angstroms;

[0051] The preparation process o...

Embodiment 2

[0066] A kind of anti-reflection film for OLED flexible display of the present embodiment, its structure comprises:

[0067] The base film, its raw materials include PMMA and COP, the thickness of the base film is 756 angstroms;

[0068] Magnesium fluoride substrate, which is deposited on the surface of the base film, the thickness of the magnesium fluoride substrate is 208 angstroms;

[0069] Al2O3 film layer, which is deposited on the surface of the magnesium fluoride substrate, the thickness of the Al2O3 film layer is 336 angstroms;

[0070] Hafnium oxide film layer, which is deposited on the surface of the aluminum oxide film layer, the thickness of the hafnium oxide film layer is 540 angstroms;

[0071] A silicon dioxide film layer, which is deposited on the surface of the hafnium oxide film layer, and the thickness of the silicon dioxide film layer is 720 angstroms;

[0072] The preparation process of the anti-reflection film for OLED flexible display of this embodimen...

Embodiment 3

[0087] A kind of anti-reflection film for OLED flexible display of the present embodiment, its structure comprises:

[0088] The base film, its raw materials include PMMA and COP, the thickness of the base film is 756 angstroms;

[0089] Magnesium fluoride substrate, which is deposited on the surface of the base film, the thickness of the magnesium fluoride substrate is 208 angstroms;

[0090] Al2O3 film layer, which is deposited on the surface of the magnesium fluoride substrate, the thickness of the Al2O3 film layer is 336 angstroms;

[0091] Hafnium oxide film layer, which is deposited on the surface of the aluminum oxide film layer, the thickness of the hafnium oxide film layer is 540 angstroms;

[0092] A silicon dioxide film layer, the surface of which the hafnium oxide film layer is deposited, the thickness of the silicon dioxide film layer is 545 angstroms;

[0093] The preparation process of the anti-reflection film for OLED flexible display of this embodiment inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com