Double-end grounding loop resistance test method without dismounting grounding wire

A grounding loop and resistance testing technology, applied in grounding resistance measurement and other directions to achieve the effect of improving safety level, saving time and cost, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

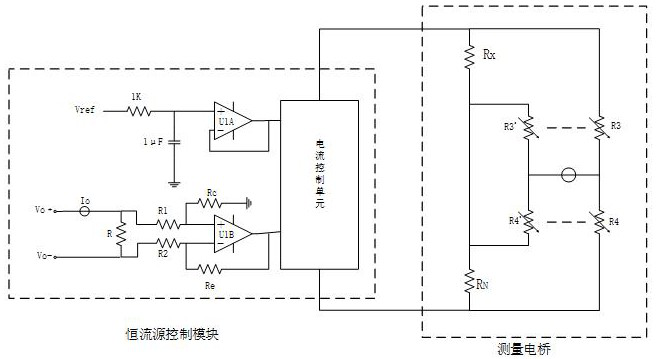

[0022] Embodiment 1: as Figure 1-Figure 3 As shown, a double-terminal grounding loop resistance test method without removing the grounding wire, the specific steps of the method are as follows:

[0023] Step 1. Safety measures for power failure arrangement: disconnect the circuit breaker, open the isolating switches on both sides of the circuit breaker, and close the grounding switches on both sides of the circuit breaker;

[0024] Step2. After the safety measures are arranged, after performing the on-site safety procedures, close the circuit breaker;

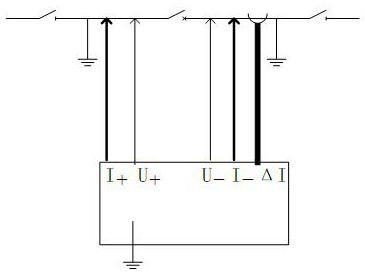

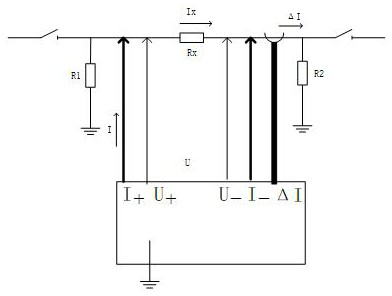

[0025] Step3. When the circuit breaker is in the closed position, arrange the test line;

[0026] Step4. After the wiring is completed, select the output to be above 100A, and run the test according to the following test method;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com