Efficient quartz sand dehydrator

A technology of dehydrator and quartz sand, which is applied in the field of dehydration of quartz sand, can solve the problems of slow dehydration, achieve the effect of reducing water content, increasing contact surface, and good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

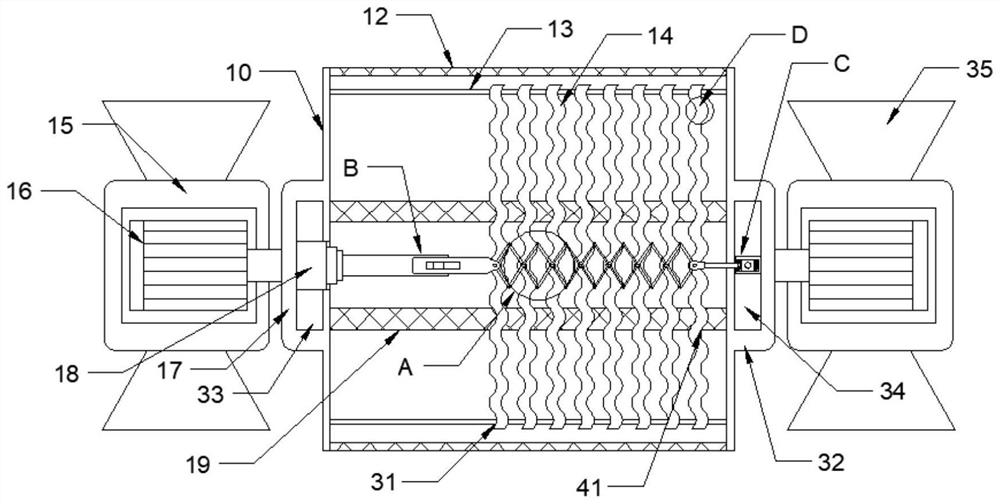

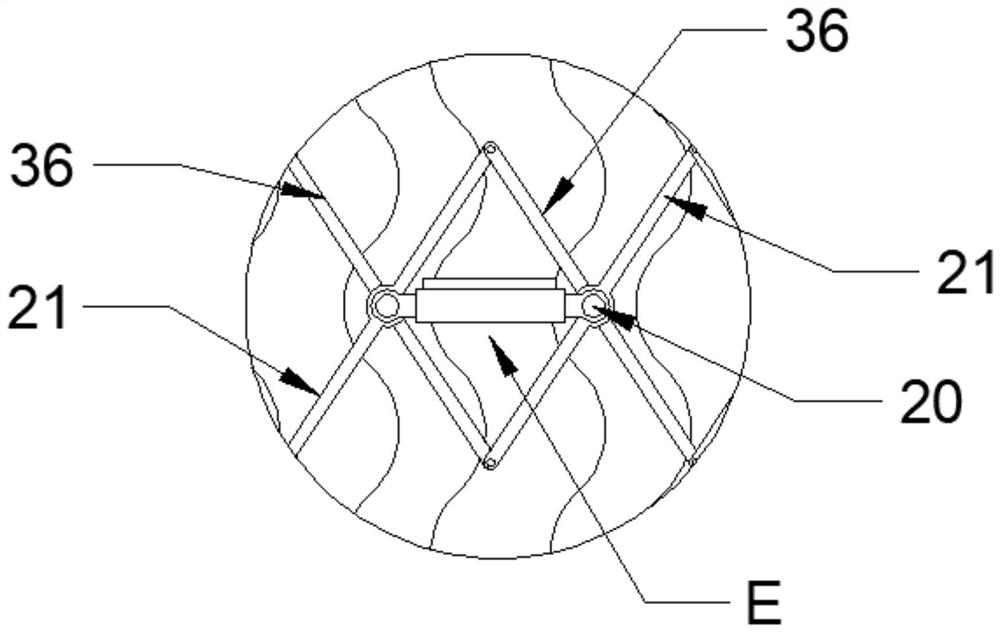

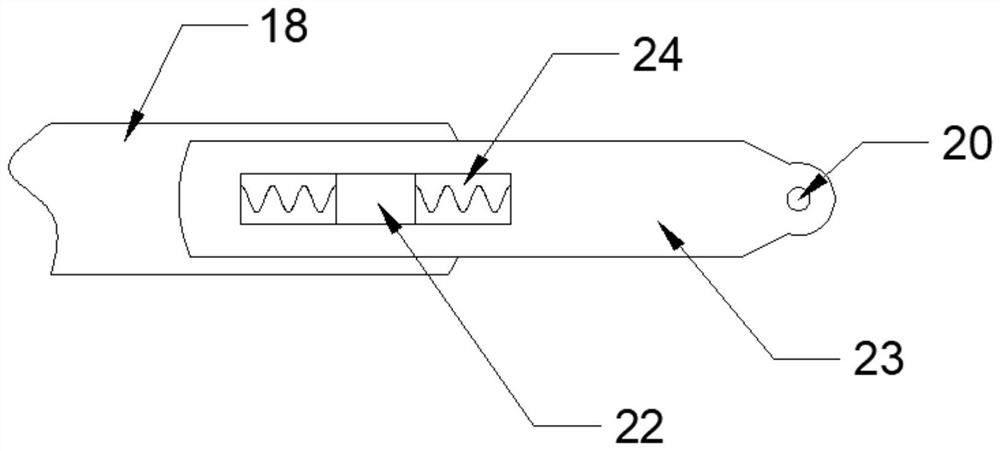

[0025] Combine below Figure 1-7 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0026] A quartz sand high-efficiency dehydrator described in conjunction with accompanying drawings 1-7 includes a support base 35 and two sets of baffles 10, the support base 35 is rotatably connected to two sets of baffles 10, and the two sets of baffles 10 are Guide rods 13 are arranged between them, and dewatering plates 14 are arranged between the two groups of baffle plates 10, and the dewatering plates 14 are linearly arrayed along the guide rods 13, and the dewatering plates 14 are provided with guide chute 31, The guide bar 13 is slidably provided in the guide chute 31, and the two sets of baffle plates 10 are provided with a screen 12 on the outside, the upper side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com