Noise control method and device of smoke exhaust ventilator, smoke exhaust ventilator and storage medium

A range hood and noise control technology, which is applied in the noise control of range hoods, range hoods and storage media, can solve the problems of providing stronger suction and increasing the noise of range hoods, and achieve the effect of strong suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

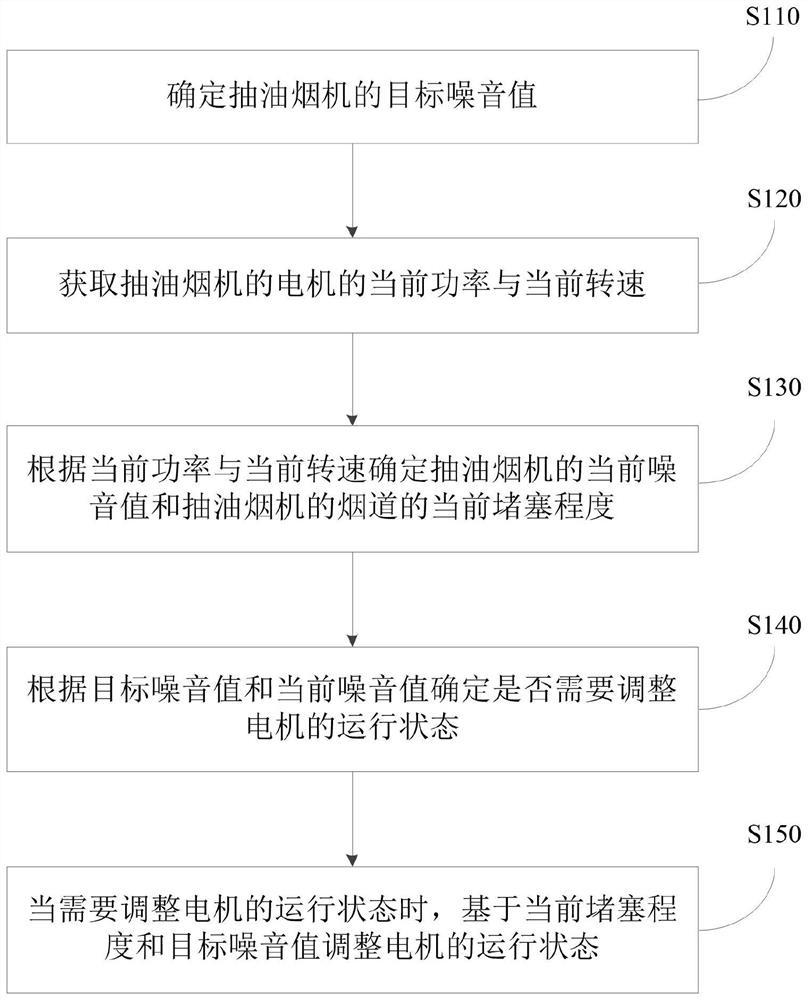

[0029] figure 1 It is a flow chart of a noise control method for a range hood provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation where constant noise is maintained under the condition that the flue blockage degree of the range hood changes. The method can be composed of The noise control device of the range hood built in the range hood is implemented, specifically including the following steps:

[0030] S110. Determine the target noise value of the range hood.

[0031] The noise of range hoods usually changes with the degree of blockage of the flue. The blockage here not only refers to the blockage of the flue by oil or impurities in the flue, but also refers to the situation when multiple range hoods share one flue. The influence of smoke exhaust on each other. For example, during the peak season of cooking, residents of the same unit in a building share a flue, and a large amount of smoke and dust are discharged in a concentra...

Embodiment 2

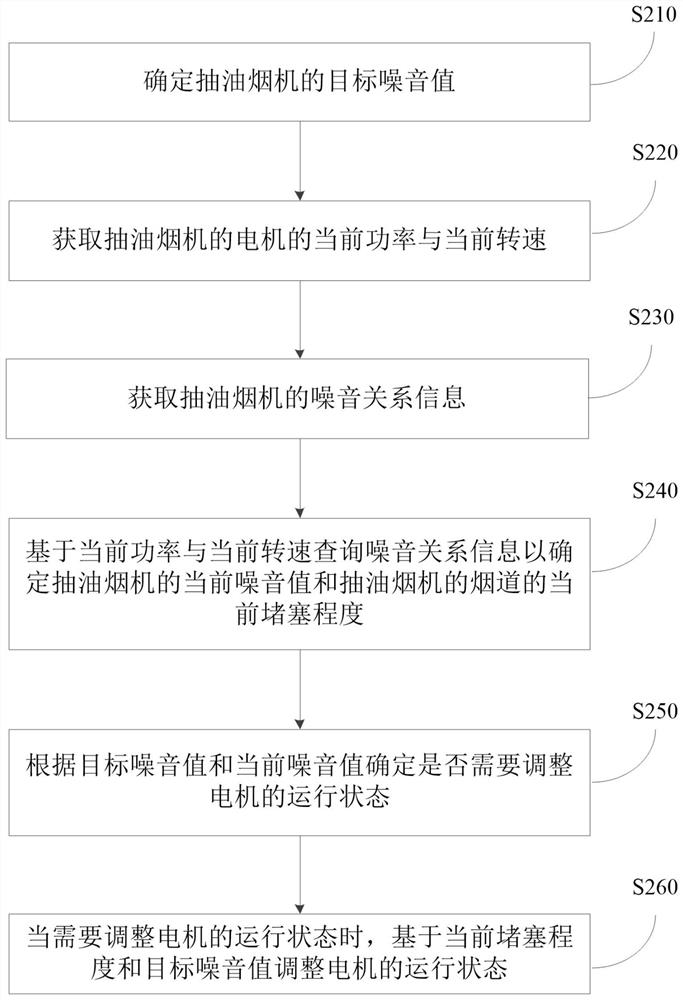

[0054] figure 2 It is a flow chart of a noise control method for a range hood provided by Embodiment 2 of the present invention. This embodiment is applicable to the situation of maintaining constant noise under the condition that the flue clogging degree of the range hood changes, and is a comparison of the embodiment Further refinement of one, the method can be implemented by the noise control device of the range hood built in the range hood, specifically including the following steps, wherein the steps that are the same as or similar to those in the first embodiment will not be repeated:

[0055] S210. Determine the target noise value of the range hood.

[0056] S220. Obtain the current power and current rotational speed of the motor of the range hood.

[0057] S230. Obtain noise relationship information of the range hood.

[0058] The noise relationship information of the range hood can be presented in the form of a table as in Embodiment 1, or can be abstracted into a ...

Embodiment 3

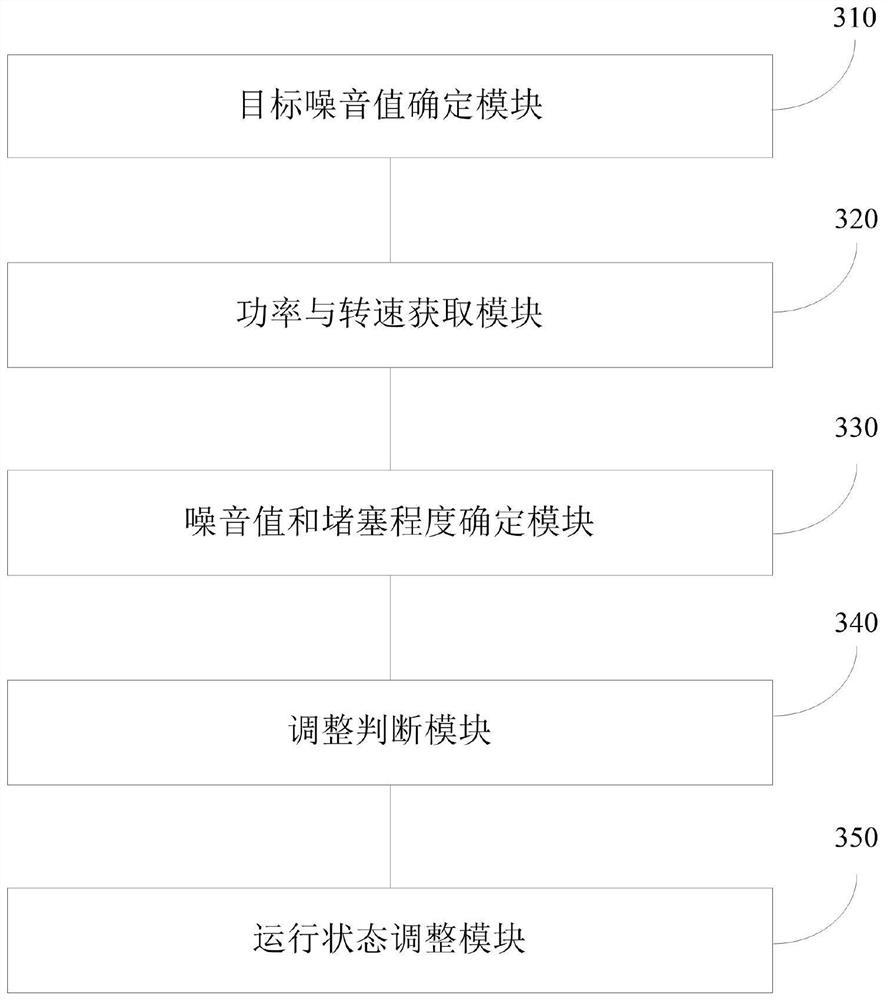

[0075] image 3 It is a structural diagram of a noise control device for a range hood provided in Embodiment 3 of the present invention. The noise control device for a range hood provided in this embodiment can implement the noise control of a range hood provided in any embodiment of the present invention. The method has corresponding functional modules and beneficial effects for executing the method.

[0076] A noise control device for a range hood, comprising:

[0077] A target noise value determining module 310, configured to determine the target noise value of the range hood;

[0078] A power and rotation speed acquisition module 320, configured to acquire the current power and current rotation speed of the motor of the range hood;

[0079] A noise value and blockage degree determination module 330, configured to determine the current noise value of the range hood and the current blockage degree of the flue of the range hood according to the current power and the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com