Reinforced soil retaining dam

A technology for retaining dams and reinforced soil, which is applied in the direction of dams, barrages, and water conservancy projects, and can solve the problems of project investment that cannot overflow the dam body, high requirements for the nature of the project, and increased project investment, so as to solve the problems of overflow and water consumption. Energy problems, improvement of deformation conditions, and the effect of reducing engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

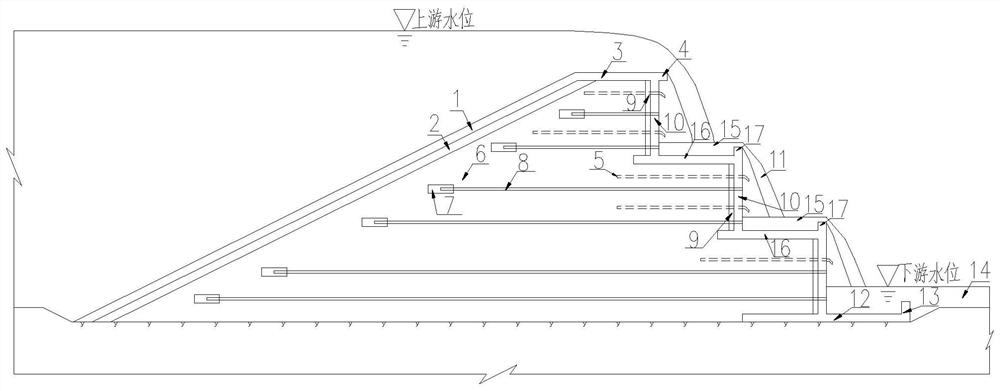

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 1 As shown, the present invention includes a retaining dam base 6 made of reinforced soil, and the upstream surface of the retaining dam base 6 is a slope whose top is inclined downstream, and the upstream surface of the retaining dam base 6 is in turn from the inside to the outside. A cushion layer 2 and a slope concrete seepage-proof panel 1 are arranged, and a top concrete seepage-proof panel 3 is arranged on the top of the base 6 of the retaining dam. The top concrete seepage-proof panel 3 is combined with the slope concrete seepage-proof panel 1 to form a whole Strict anti-seepage overall, the downstream end of the top concrete anti-seepage panel 3 is provided with a sill 4, the downstream slope of the retaining dam base 6 is provided with a concrete support panel 10, and the downstream slope of the retaining dam base 6 is an upright slope. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com