Modulated nickel/cobalt bimetal MOF (Metal Organic Framework)-based electrocatalyst as well as preparation method and application thereof

An electrocatalyst and bimetallic technology, applied in the field of electrocatalysis, can solve the problems of poor conductivity and low catalytic activity of MOF, and achieve the effect of improving conductivity, high current density and low initial potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This example has prepared a kind of modulation nickel / cobalt bimetallic MOF-based catalyst, and specific preparation method comprises the following steps:

[0050] A piece of nickel foam (1 cm × 3 cm) was ultrasonically cleaned sequentially with 3M hydrochloric acid, deionized water, and absolute ethanol, and then dried in a vacuum.

[0051] Terephthalic acid (0.075M) and ferrocenecarboxylic acid (0.01M) were dissolved in 5 mL of DMF. Then, 1 mL of 0.2M NaOH solution was added. After that, the above solution was slowly mixed with 5 mL of DMF solution in which nickel nitrate hexahydrate (0.019M) and cobalt nitrate hexahydrate (0.056M) were dissolved in a 30 mL autoclave filled with nickel foam (1 cm × 3 cm). Finally, the autoclave was heated at 100°C for 14 hours. The nickel foam was removed, washed twice each with DMF and ethanol, and dried under vacuum. The loading of NiCoMOF-Fc material on nickel foam is about 1.4 mg cm -2 .

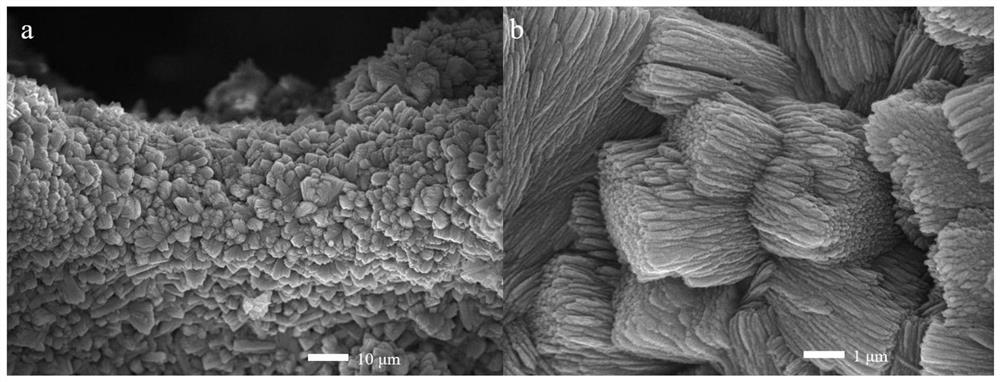

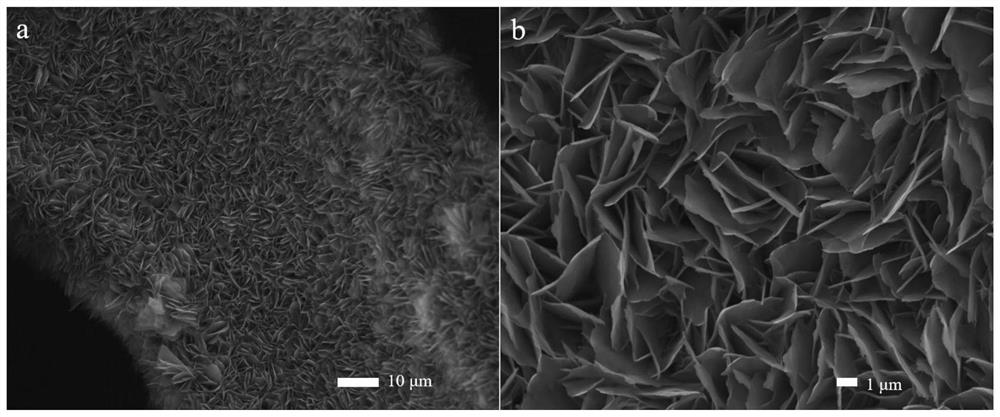

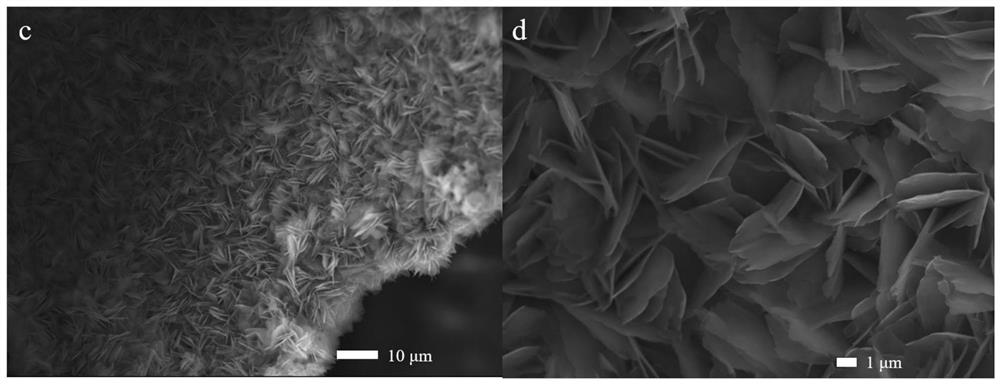

[0052] The electron microscope image...

Embodiment 2

[0054] This example has prepared a kind of modulation nickel / cobalt bimetallic MOF-based catalyst with the different ratio of embodiment 1, and concrete preparation method comprises the following steps:

[0055] Terephthalic acid (0.075M) and ferrocenecarboxylic acid (0.01M) were dissolved in 5 mL of DMF. Then, 1 mL of 0.2M NaOH solution was added. After that, the above solution was slowly mixed with 5 mL of DMF solution in which nickel nitrate hexahydrate (0.013M) and cobalt nitrate hexahydrate (0.063M) were dissolved in a 30 mL autoclave filled with nickel foam (1 cm × 3 cm). Finally, the autoclave was heated at 100°C for 14 hours. The nickel foam was removed, washed twice each with DMF and ethanol, and dried under vacuum. The loading of NiCoMOF-Fc material on nickel foam is about 1.4 mg cm -2 .

Embodiment 3

[0057] This example has prepared a kind of modulation nickel / cobalt bimetallic MOF-based catalyst with the different ratio of embodiment 1, and concrete preparation method comprises the following steps:

[0058] Terephthalic acid (0.075M) and ferrocenecarboxylic acid (0.01M) were dissolved in 5 mL of DMF. Then, 1 mL of 0.2M NaOH solution was added. After that, the above solution was slowly mixed with 5 mL of DMF solution in which nickel nitrate hexahydrate (0.063M) and cobalt nitrate hexahydrate (0.013M) were dissolved in a 30 mL autoclave filled with nickel foam (1 cm × 3 cm). Finally, the autoclave was heated at 100°C for 14 hours. The nickel foam was removed, washed twice each with DMF and ethanol, and dried under vacuum. The loading of NiCoMOF-Fc material on nickel foam is about 1.4 mg cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com