Preparation method of high-performance organic synthetic fiber rubber compound

A synthetic fiber and high-performance technology, which is applied in the field of preparation of high-performance organic synthetic fiber compound rubber, can solve the problem of uneven dispersion of high-performance organic synthetic fiber, easy wrapping of high-performance synthetic fiber, and unfavorable dispersion of high-performance synthetic fiber and other problems, to achieve excellent performance and quality stability, improve performance and quality stability, and shorten the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiments 1-14 provide a method for preparing high-performance organic synthetic fiber rubber compound, which will be described below by taking Embodiment 1 as an example.

[0039] The preparation method of the high-performance organic synthetic fiber rubber compound that embodiment 1 provides, its steps are:

[0040] S1. Add 2kg of carbon black to 10kg of chloroprene rubber, mix for 200s at a speed of 30r / min, and discharge at 100°C to make a masterbatch;

[0041] S2. Cool the masterbatch prepared in step S1 to 25°C, then add 2kg of aramid fiber, put it into the internal mixer, and stir for 200s at a speed of 30r / min; then add 0.2kg of anti-aging agent RD to the internal mixer , 0.2kg anti-aging agent ODA, 0.2kg stearic acid, 0.8kg paraffin oil and 4kg carbon black, mixed at a speed of 25r / min for 400s, and deglued at 110°C;

[0042] S3. Finally, 0.5 kg of zinc oxide, 0.3 kg of magnesium oxide and 0.05 kg of accelerator ETU are put into the mixture. After mixing eve...

Embodiment 2-3

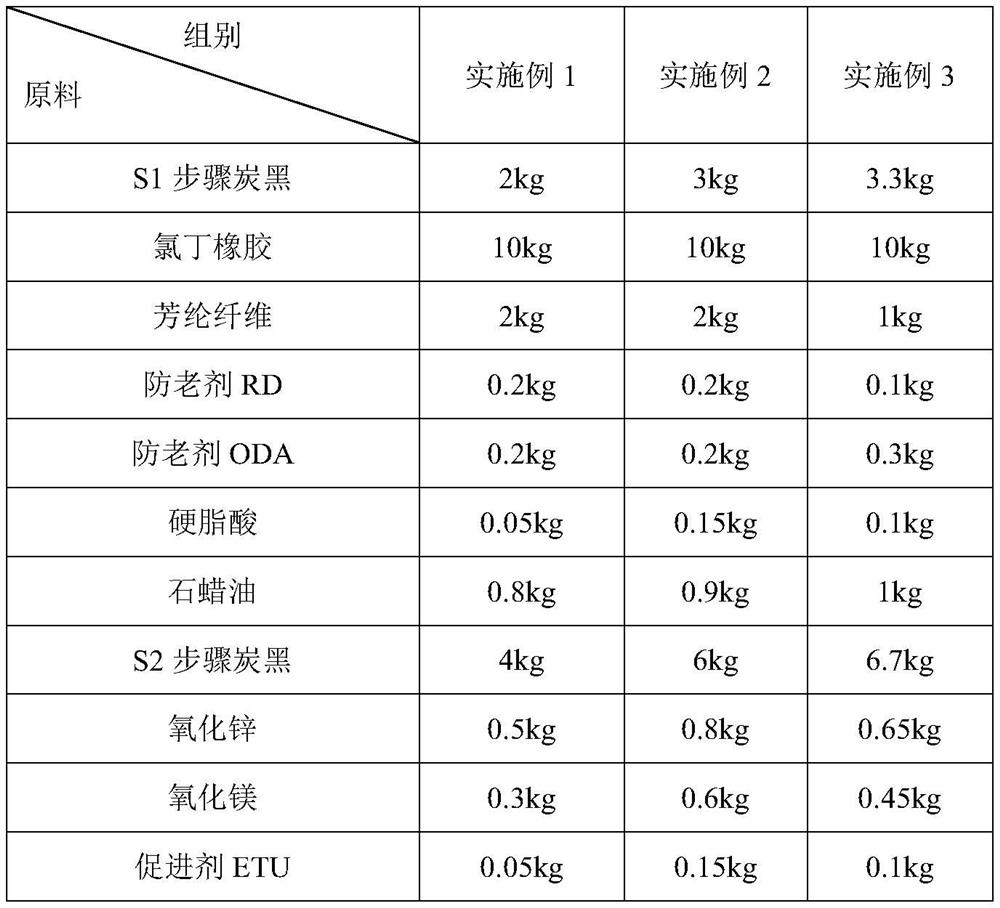

[0043] Examples 2-3 are different from Example 1 in that the quality of each preparation raw material is different, see Table 1 for details.

[0044] The quality of each preparation raw material of table 1 embodiment 1-3

[0045]

Embodiment 4-7

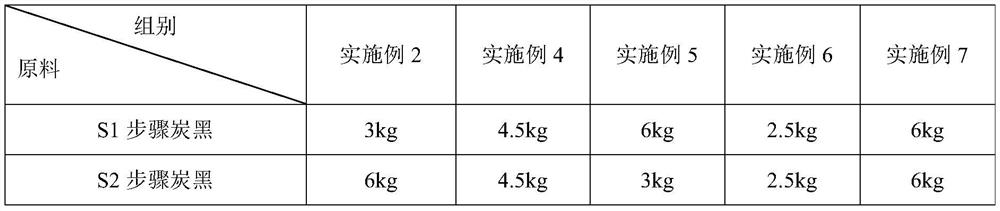

[0046] Examples 4-7 are different from Example 2 in that the quality of the carbon black in the S1 step and the carbon black in the S2 step are different, see Table 2 for details.

[0047] Table 2 embodiment 2,4-7S1 and the quality of S2 step carbon black

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com