Aeration system for organic fertilizer composting

A technology of aeration system and organic fertilizer, which is applied in the direction of organic fertilizer, organic fertilizer preparation, biological organic part treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

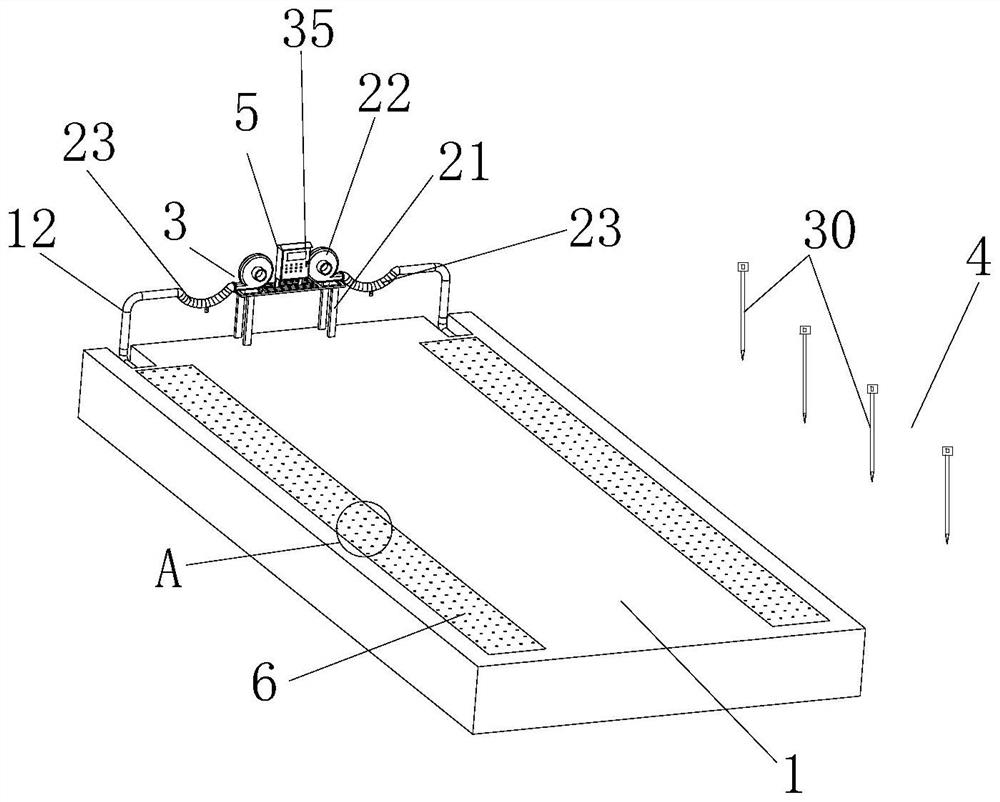

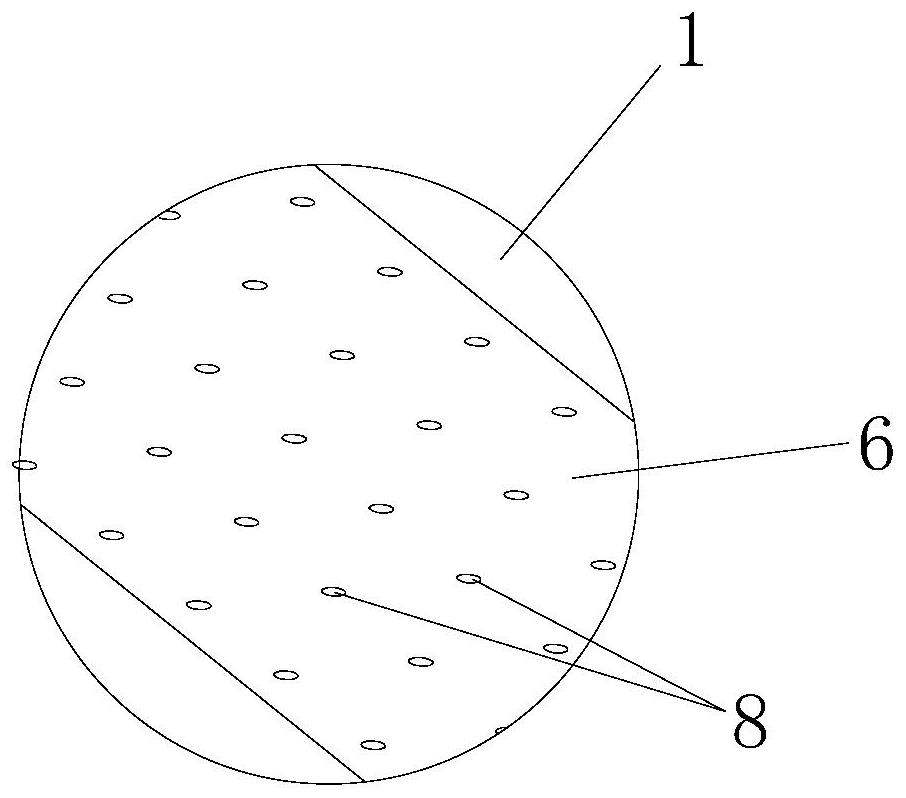

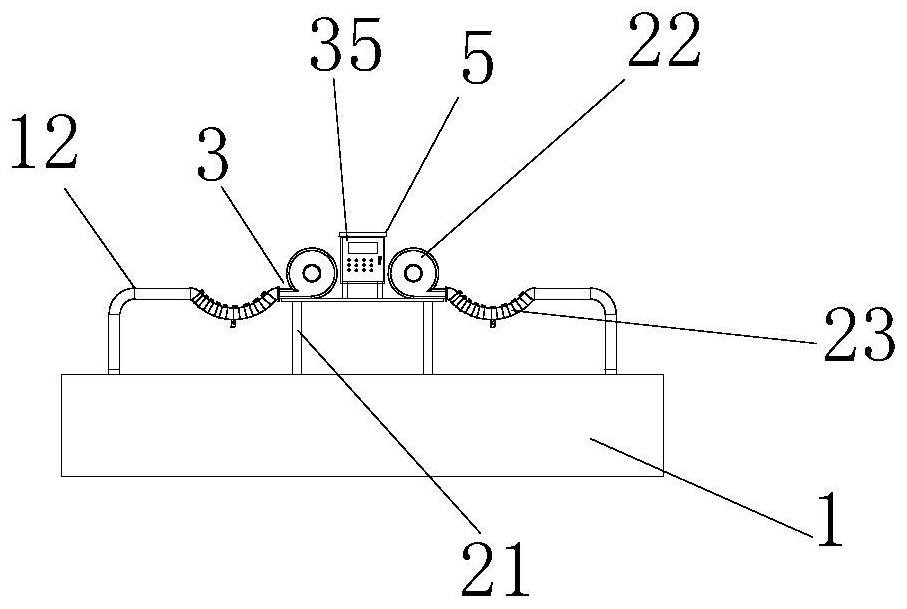

[0028] like Figure 1-10 As shown, an aeration system for organic fertilizer composting includes an air channel 2 opened on the ground 1, an air supply mechanism 3 for supplying air to the air channel 2, a temperature detection mechanism 4 and a control mechanism 5. The channel 2 gradually narrows from one end to the other end, and the upper end of the air channel 2 is provided with a cover plate 6, and both sides of the upper end of the air channel 2 are also provided with concave edges 7 for supporting the cover plate 6, and the concave edges 7 are lower than the ground 1. In order to facilitate the disassembly and assembly of the cover plate 6, the cover plate 6 in the present application selects a plurality of steel plates continuously arranged on the concave edge 7, and the length of each steel plate is 1m. The upper end surface of the cover plate 6 is flush with the ground 1 , and air holes 8 passing through the upper and lower end surfaces of the cover plate 6 are dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com