Protective device for textile fabric laser printing

A laser printing and protective device technology, applied in printing devices, printing, typewriters, etc., can solve problems such as danger and labor consumption, and achieve the effect of ensuring safety and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

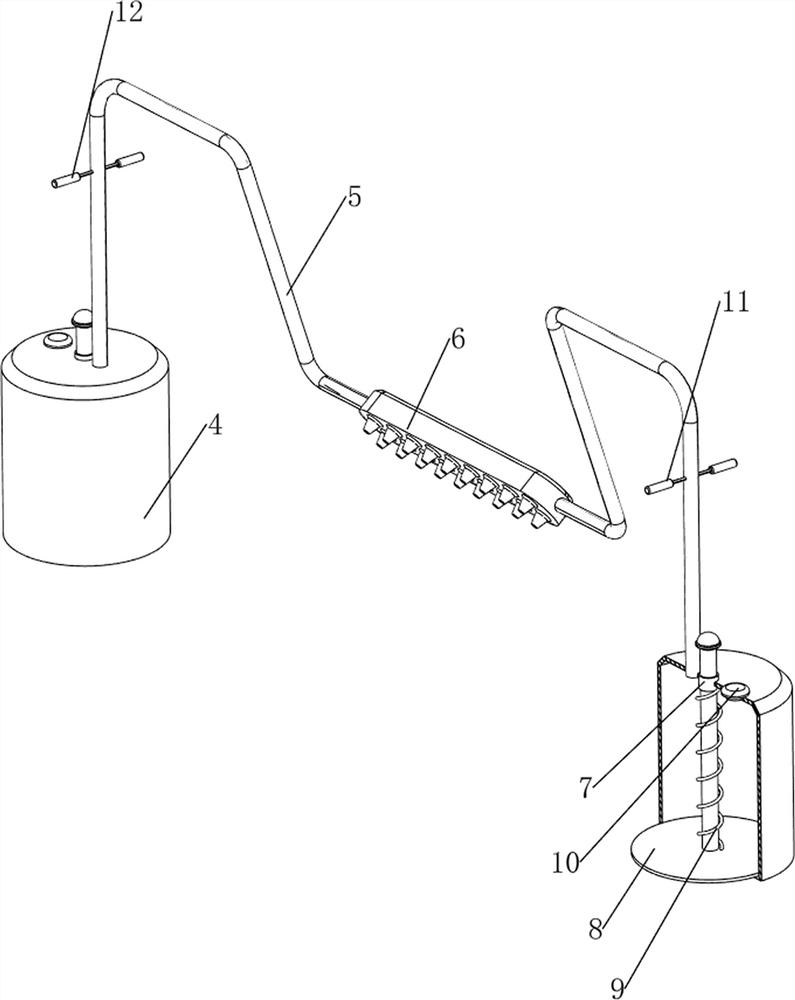

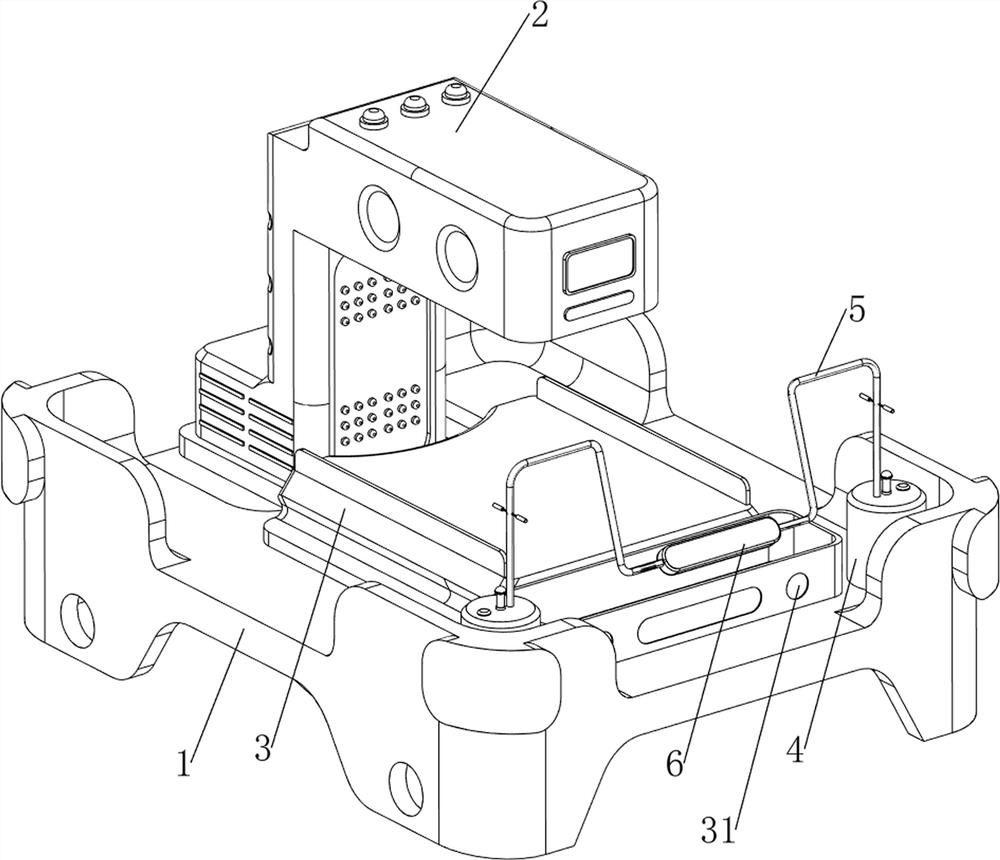

[0039] A guard for laser printing of textiles such as Figure 1-7As shown, it includes a support plate 1, a laser printer 2, a first fixed plate 3, a fixed frame 31, a water tank 4, a water pipe 5, a nozzle 6, a sealing ring 7, a piston plate 8, a first spring 9, a plug 10, a first Turning plate 11, second turning plate 12, protective mechanism 13 and material pushing mechanism 14, laser printer 2 is installed on the rear side of the top of support plate 1, the first fixed plate 3 is connected with the top of support plate 1, and the first fixed plate 3 is positioned at the laser The front side of the printer 2, the upper part of the front side of the laser printer 2 is located above the first fixed plate 3, the front side of the top of the support plate 1 is connected with a fixed frame 31, the fixed frame 31 is located at the front side of the first fixed plate 3, and the top of the fixed frame 31 is lower than the first fixed plate 3. On the top of a fixed plate 3, two wate...

Embodiment 2

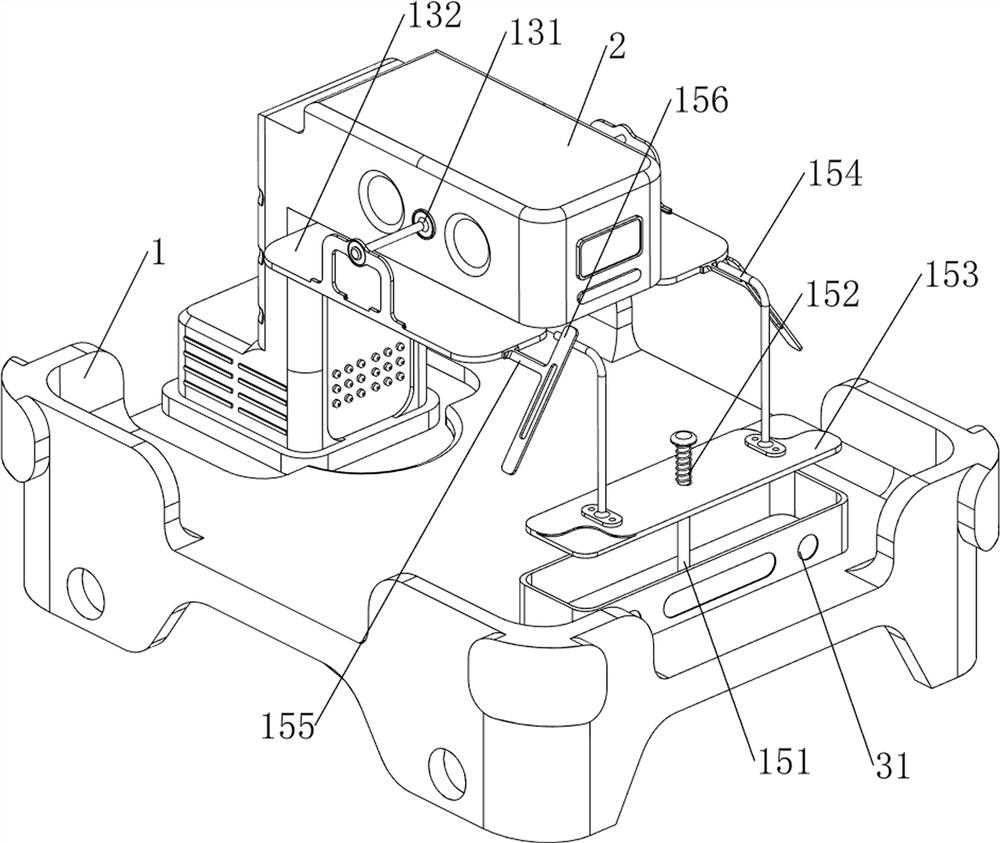

[0044] On the basis of Example 1, such as figure 1 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 Shown, also comprise extruding mechanism 15, extruding mechanism 15 comprises second guide rod 151, second spring 152, second movable plate 153, second fixed rod 154, connecting rod 155 and inclined plate 156, fixed frame 31, a second guide rod 151 is connected in the middle of the inner bottom, a second movable plate 153 is slidably connected to the second guide rod 151, a second spring 152 is set on the top of the second guide rod 151, and the two ends of the second spring 152 are respectively connected to The top of the second movable plate 153 and the top of the second guide rod 151, the top of the second movable plate 153 is connected with two second fixed rods 154, and the two second fixed rods 154 are left and right symmetrically arranged, and the front side of the first movable plate 132 is connected There is a connecting rod 155, and t...

Embodiment 3

[0051] On the basis of Example 2, such as figure 1 , Figure 14 and Figure 15 As shown, a fixing mechanism 18 is also included, and the fixing mechanism 18 includes a fixing frame 181, a second movable rod 182, a third fixing plate 183, a fifth spring 184 and a connecting plate 185, and the top of the support plate 1 is connected with two fixing frames 181, the two fixed mounts 181 are symmetrically arranged left and right, and the upper part of the side where the two fixed mounts 181 are close to each other is slidably connected with a second movable rod 182, the second movable rod 182 is located above the first fixed plate 3, and the second movable rod 182 The bottom of the rod 182 is connected with the third fixed plate 183, the second movable rod 182 is covered with the fifth spring 184, the two ends of the fifth spring 184 are respectively connected on the second movable rod 182 and the third fixed plate 183, the third fixed plate A connecting plate 185 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com