Magnetic attraction type printing head sheet

A printing head and magnetic suction technology, which is applied in printing and other directions, can solve the problems of inconsistent printing density, new users do not know how to open the cover, and different font depths, etc., to achieve the effect of protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

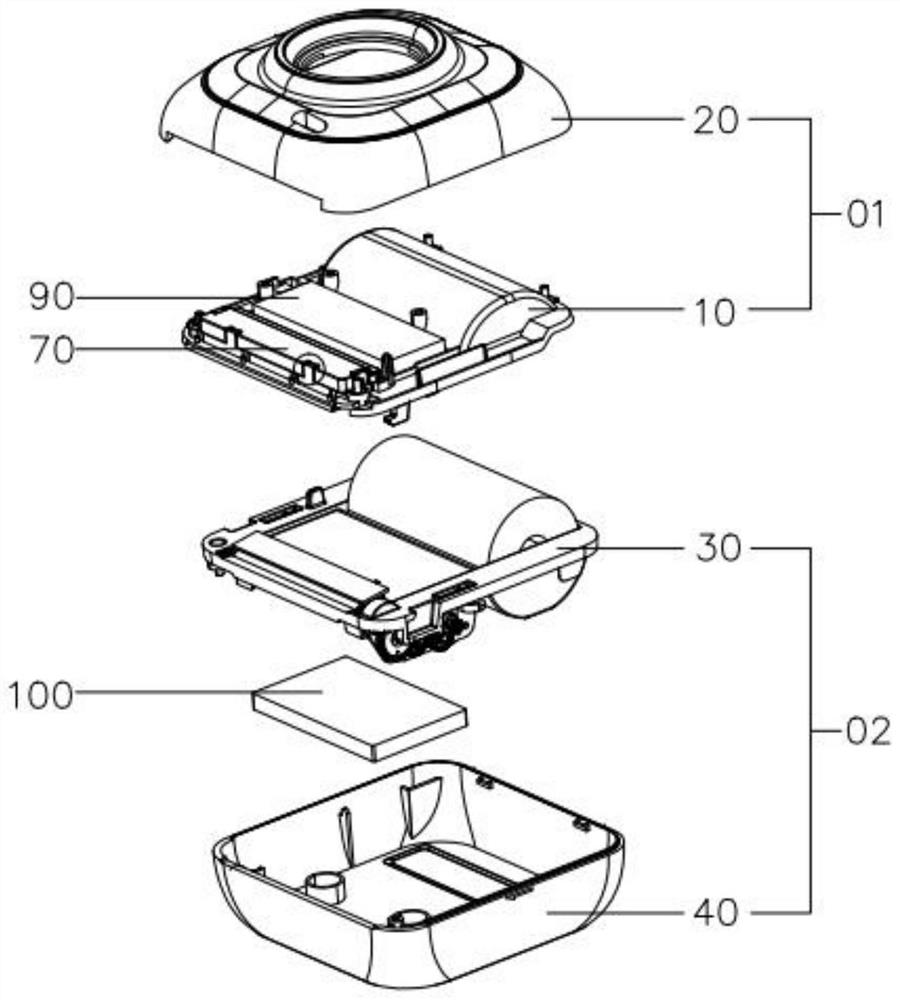

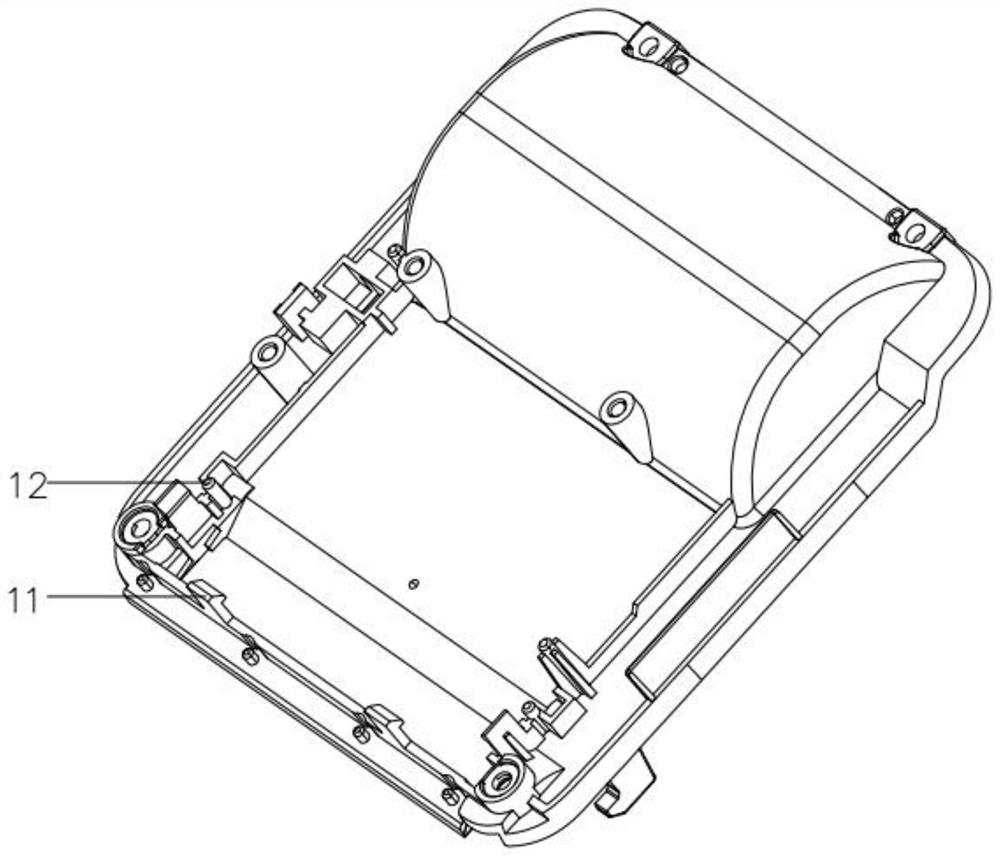

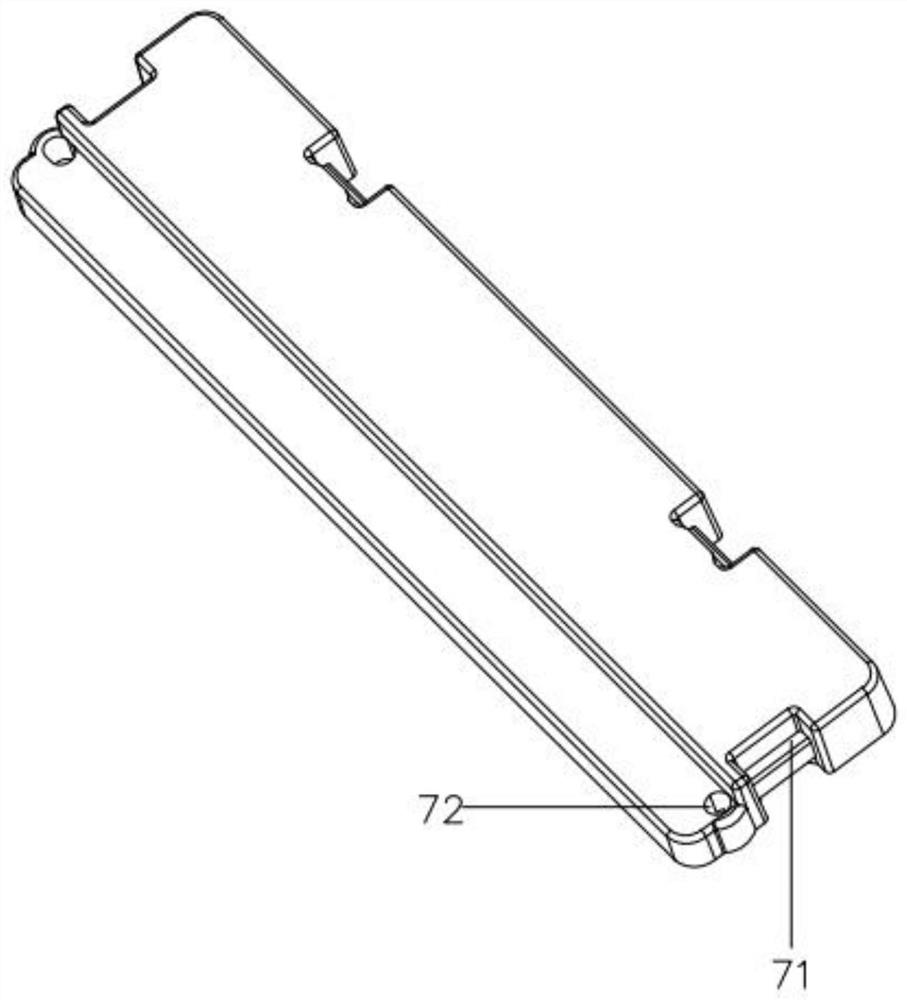

[0030] see Figures 1 to 6 , is a magnetic suction type print head sheet as Embodiment 1 of the present invention, including an upper bracket 10, a thermal print head sheet 50, and a first electromagnet 60 for fixing the thermal print head sheet 50, setting On the upper bracket 10 and the second electromagnet 70 corresponding to the first electromagnet 60, the first electromagnet 60 is movably connected with the upper bracket 10; specifically, the upper bracket 10 is provided with a place for placing the first electromagnet 60 slot, and is restricted in the placement slot by the second magnet.

[0031] This embodiment cancels the fixed structure of the original thermal printing head sheet 50, that is, a spring is used to exert a pressure on the head sheet, and the head sheet and the rubber roller 80 are closely attached to achieve the printing effect, but this structure is easy to be damaged due to the force of the spring. Different results in inconsistencies in printing dens...

Embodiment 2

[0034] see Figures 1 to 4 , is a kind of printer as embodiment 2 of the present invention, has adopted a kind of magnetic suction type print head sheet of embodiment 1 of the present invention; A third electromagnet 90 is provided, and a fourth electromagnet 100 corresponding to the third magnet is provided on the lower bracket 30 . The third electromagnet 90 and the fourth electromagnet 100 are attracted to each other to close the upper bracket 10 and the lower bracket 30 .

[0035] The printer also includes an upper casing 20 arranged outside the upper bracket 10, and a lower casing 40 arranged outside the lower bracket 30; the upper bracket 10 and the upper casing form the lower cover group 02, and the lower bracket 30 and the lower casing form the lower cover group 02, and the upper cover set 01 and the lower cover set 02 are detachably connected through the third electromagnet 90 and the fourth electromagnet 100. The third electromagnet 90 is disposed close to the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com