A custom label printing device for tea outer packaging

A printing device and outer packaging technology, applied in packaging, transportation, packaging, printing, etc., can solve the problems of low label printing efficiency, slow printing speed, and small printing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

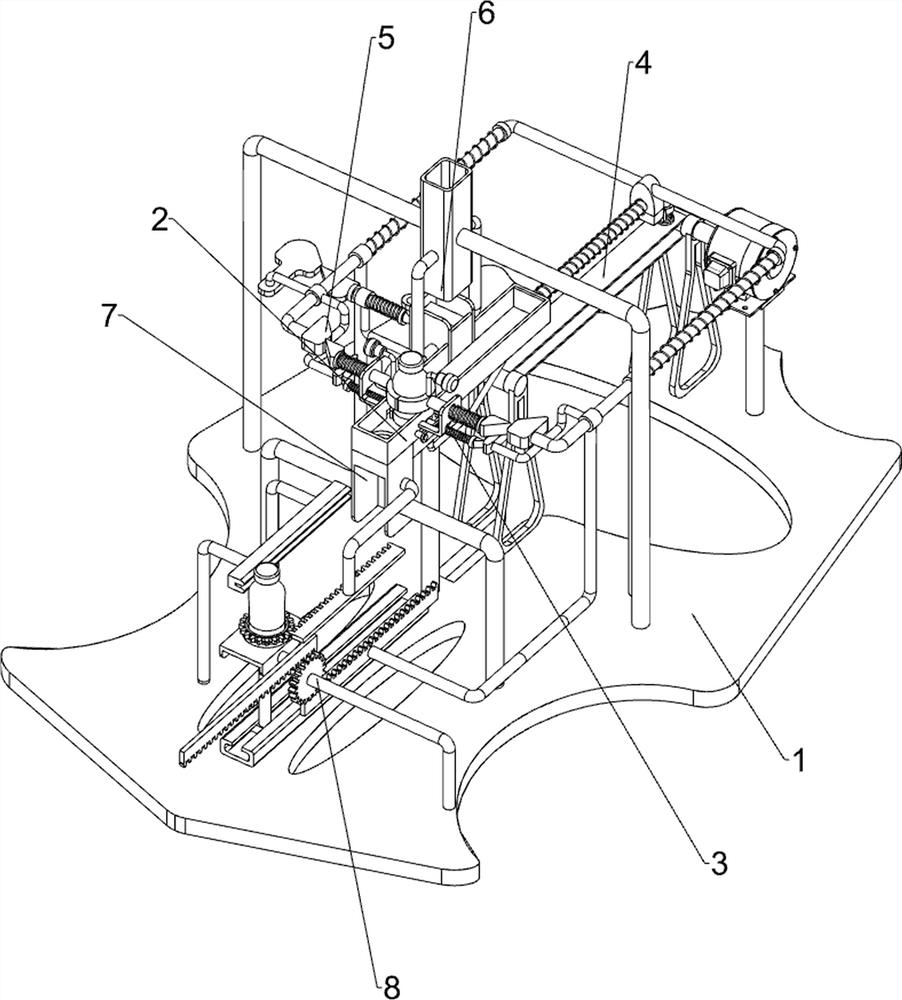

[0070] A customized label printing device for tea outer packaging, such as figure 1 As shown, it includes a bottom plate 1, a printing mechanism 2, a clamping mechanism 3 and a pushing mechanism 4. The bottom plate 1 is provided with a printing mechanism 2 in the middle, a clamping mechanism 3 is provided on the front side of the printing mechanism 2, and a rear side is provided on the bottom plate 1. There is a pushing mechanism 4.

[0071] When people want to print labels on the outer packaging of tea, they can use the customized label printing device for the outer packaging of tea. First, the user puts the tea cans into the pushing mechanism 4, and pushes the tea cans through the pushing mechanism 4. In the clamping mechanism 3, the tea can is clamped, and then the label printing is performed on the outer packaging of the tea can through the printing mechanism 2, so as to realize the effect of label printing.

Embodiment 2

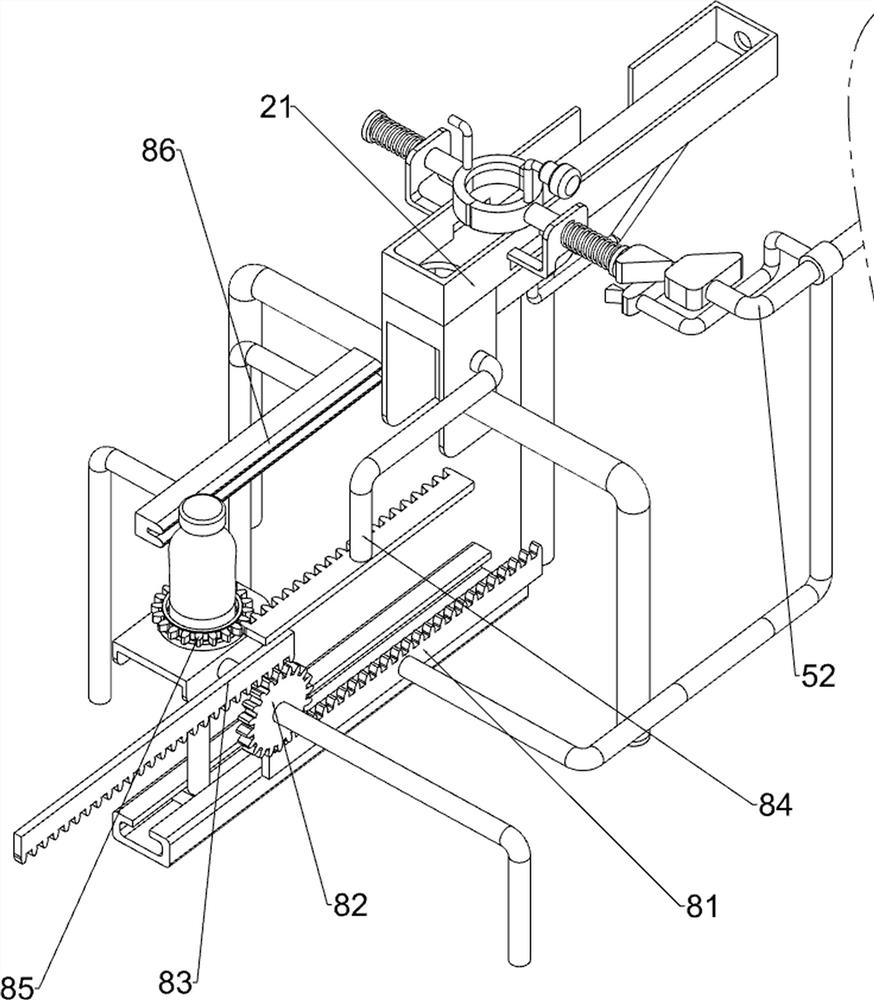

[0073] On the basis of Example 1, as Figure 2-Figure 4 As shown, the printing mechanism 2 includes a placing table 21, a first sliding sleeve plate 22, a sliding printing plate 23 and a first spring 24. The upper and middle part of the bottom plate 1 is provided with a placing table 21, and the left and right parts of the front side of the placing table 21 Both are provided with a first sliding sleeve board 22 , the upper parts of the two first sliding sleeve boards 22 are slidably provided with a sliding printing plate 23 , and a first spring 24 is wound around each sliding printing plate 23 , and each first spring 24 The outward end is connected to the sliding printing plate 23 , and the inward end of each first spring 24 is connected to the first sliding sleeve plate 22 .

[0074] The user first places the tea can on the placing table 21, then pushes the two sliding printing plates 23 toward each other, the first spring 24 is compressed, and the sliding printing plate 23 l...

Embodiment 3

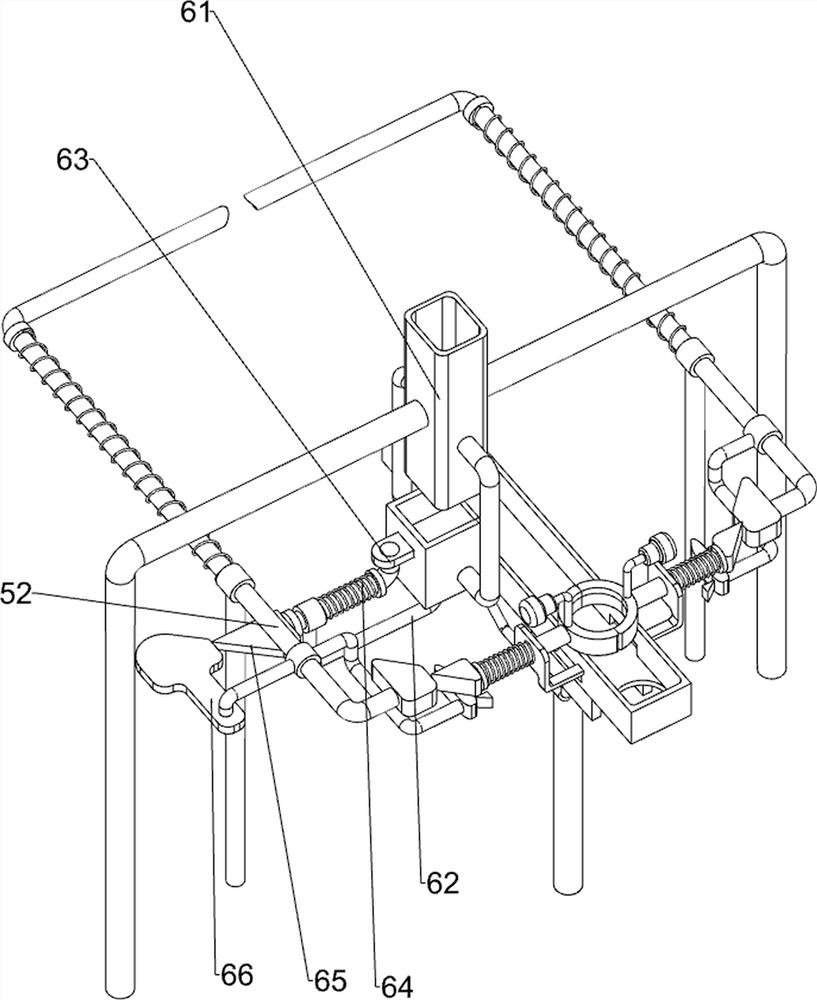

[0080] On the basis of Example 2, as Figure 5-Figure 8 As shown, it also includes an automatic printing clamping mechanism 5, the left and right sides of the base plate 1 are provided with an automatic printing clamping mechanism 5, and the automatic printing clamping mechanism 5 includes a first fixed sliding sleeve 51, a first wedge-shaped push rod 52, The first force wedge block 53, the fifth spring 54, the second wedge push rod 55 and the second force wedge block 56 are provided with first fixed sliding sleeves 51 on the left and right sides of the bottom plate 1. The upper part of the sleeve 51 is slidably provided with a first wedge-shaped push rod 52, and the rear part of the first wedge-shaped push rod 52 is connected with the push plate 47, and the outer wall of each sliding printing plate 23 is provided with a first force-bearing wedge-shaped block 53, the first The stressed wedge-shaped block 53 cooperates with the first wedge-shaped push rod 52, each first wedge-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com