Ampoule bottle chain conveying mechanism

A chain conveying and ampoule bottle technology, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of troublesome chain replacement, high labor cost, and low degree of automation of ampoule bottle printing, so as to avoid breaking and realize printing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

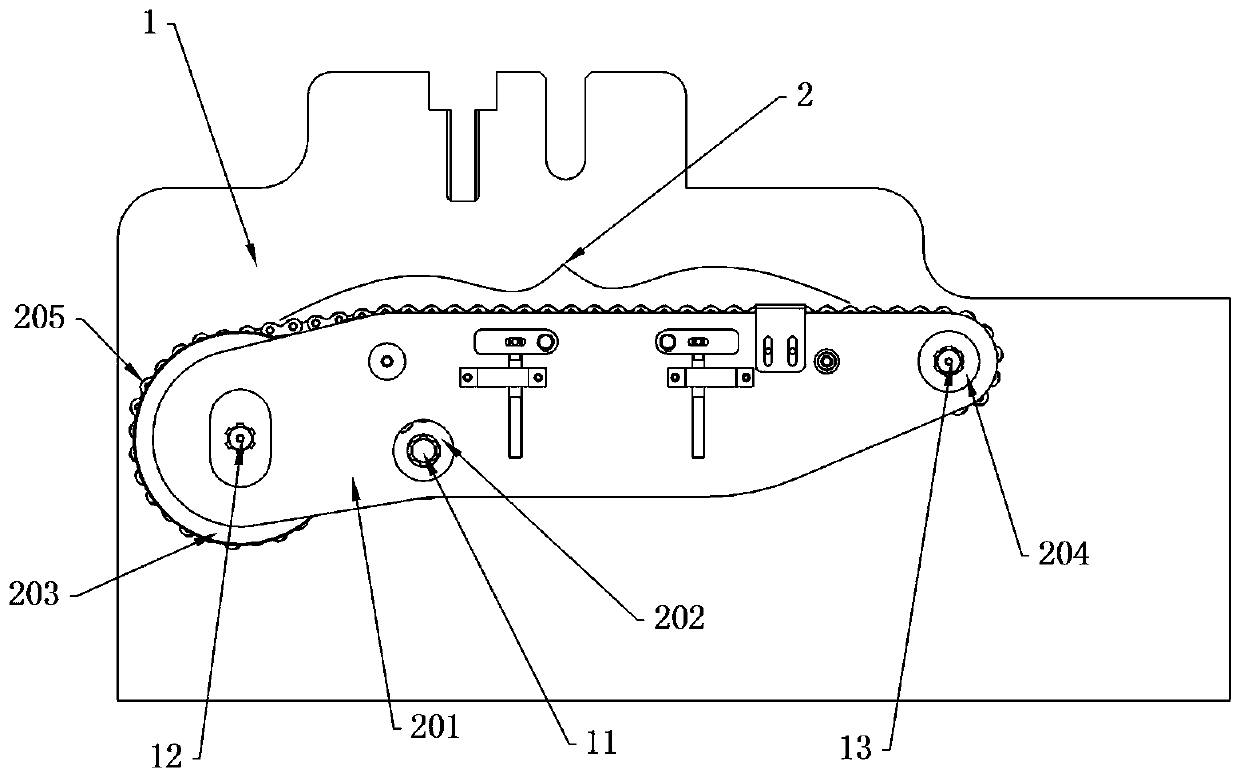

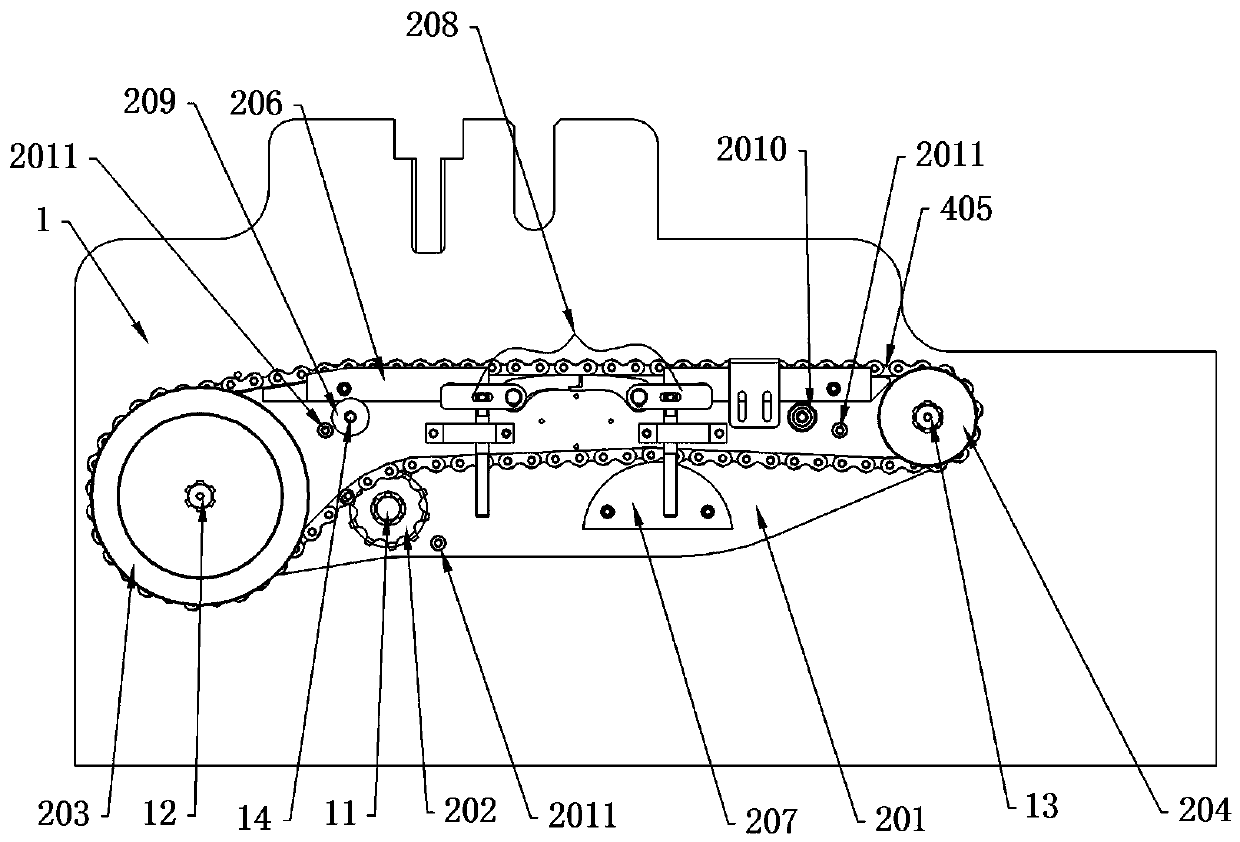

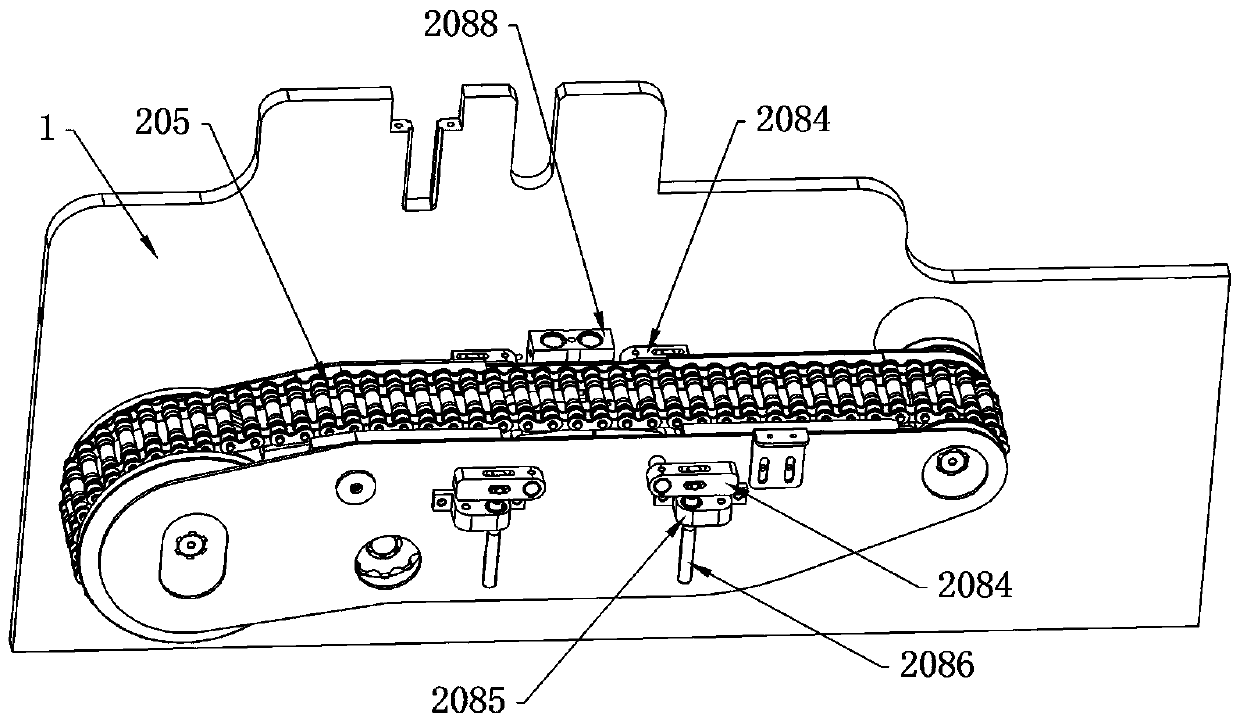

[0024] The specific embodiment of the present invention sees Figure 1-4 :

[0025] A chain delivery mechanism for ampoules, such as Figure 1-4 , including a printing and branching mounting plate 1 and a conveying body 2, the conveying body 2 includes two sprockets and a conveying chain 205 installed on the two sprockets, the conveying chain 205 is set horizontally, and the two sprockets are respectively located on the left and right sides , the top of the two sprockets is the upper part of the conveyor chain 205, and the bottom of the two sprockets is the lower part of the conveyor chain 205. Three evenly distributed quick-loading rods 14 are installed on the printing plate 1, and the conveyor body 2 It also includes two opposite chain support plates 201, the two chain support plates 201 are connected by connecting rods 2011, the two ends of the connecting rods 2011 are provided with threaded holes, the connecting rods 2011 and the chain support plates 201 are connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com