A kind of automatic cutting method of carbon fiber laminate

An automatic cutting and laminated board technology, applied in metal processing and other directions, can solve the problems of increasing cutting paths, difficult cutting, high error rate, etc., and achieve the effects of improving structural strength, fast cutting operations, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

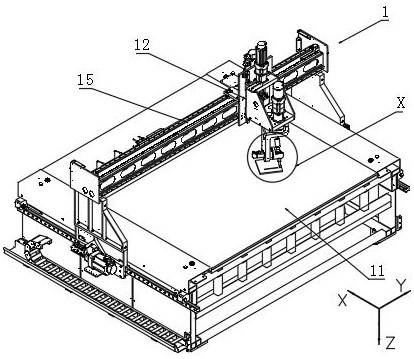

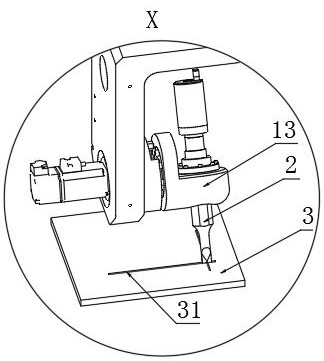

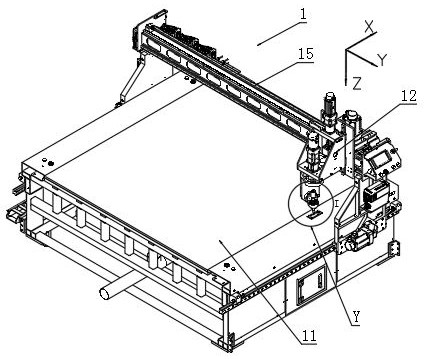

[0039] like Figure 1-6It is a schematic diagram of the structure of the present invention, an automatic cutting method for carbon fiber laminates, using a cutting machine 1 equipped with an ultrasonic cutting tool 2, and the transverse section of the blade 21 of the cutting tool 2 is a slender rhombus. The tip of the rhombus forms a cutting edge, and the plane formed by its longer diagonal fitting is the cutting edge plane 22 , the cutting surface of the cutting edge 21 of the cutting tool 2 along the cutting edge plane 22 is a triangle, and the cutting edge of the cutting edge 21 is a triangle. There is a tool tip arc 23 and a cutting edge is provided at the place, including the following steps:

[0040] S1, pretreatment, put the carbon fiber laminate material 3 to be cut in the cold storage, arrange for cutting after partial thawing; freeze it in the cold storage to -18 ℃ to -12 ℃ for storage, and then place it at room temperature 20-25 ℃ before cutting for 1 -3h.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com