Compound feed for broiler chicken in later period

A technology for compound feed and broiler chickens, applied in feed, animal feed, animal feed, etc., can solve the problems of insufficient heating operation, high moisture content, wet material spoilage, etc., and achieve sufficient heating and drying operations, protein types Complete, protein-packed results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

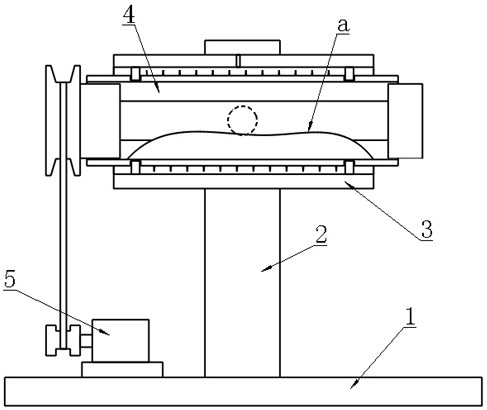

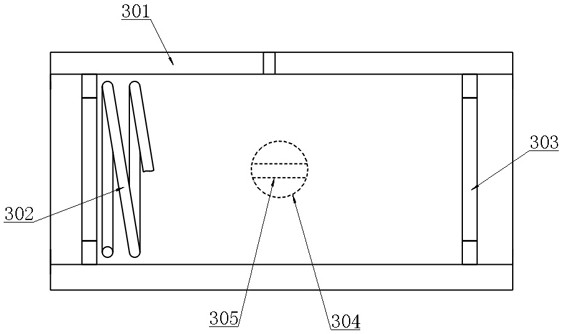

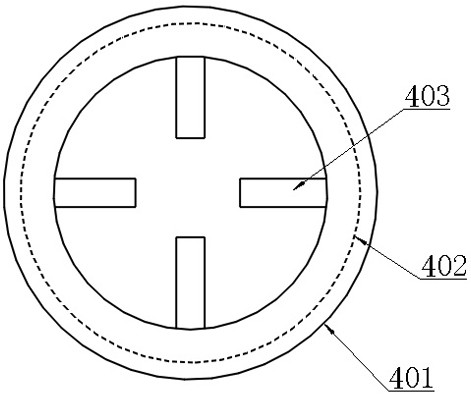

[0041] Example: as attached Figure 1-7 As shown, a broiler chicken late stage compound feed, the feed composition includes earthworm powder, snail powder, Tenebrio molitor powder and silkworm chrysalis powder, the total addition of the four powders accounts for 10-12% of the final feed weight.

[0042] In this embodiment, the four kinds of powders are the earthworm powder, snail powder, Tenebrio molitor powder and silkworm chrysalis powder, each of which has different protein types and amino acid types, which can meet the rapid growth needs of broiler chickens before slaughter .

[0043] In addition, with the addition of 10-12%, although the cost is slightly increased, the quality of the final broiler chicks is significantly improved, and the muscles are more plump and tender.

[0044] Before pulverizing, the four kinds of powders were heated and dewatered using a rotary tumble dryer respectively. The raw materials of the earthworm powder, Tenebrio molitor powder and silkworm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com