Instant flatfish food raw material flatfish pretreatment equipment

A flounder and pretreatment technology, applied in fish processing, food science, slaughtering, etc., can solve the problem of inability to clean abdominal internal organs, and achieve the effect of avoiding fishy smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

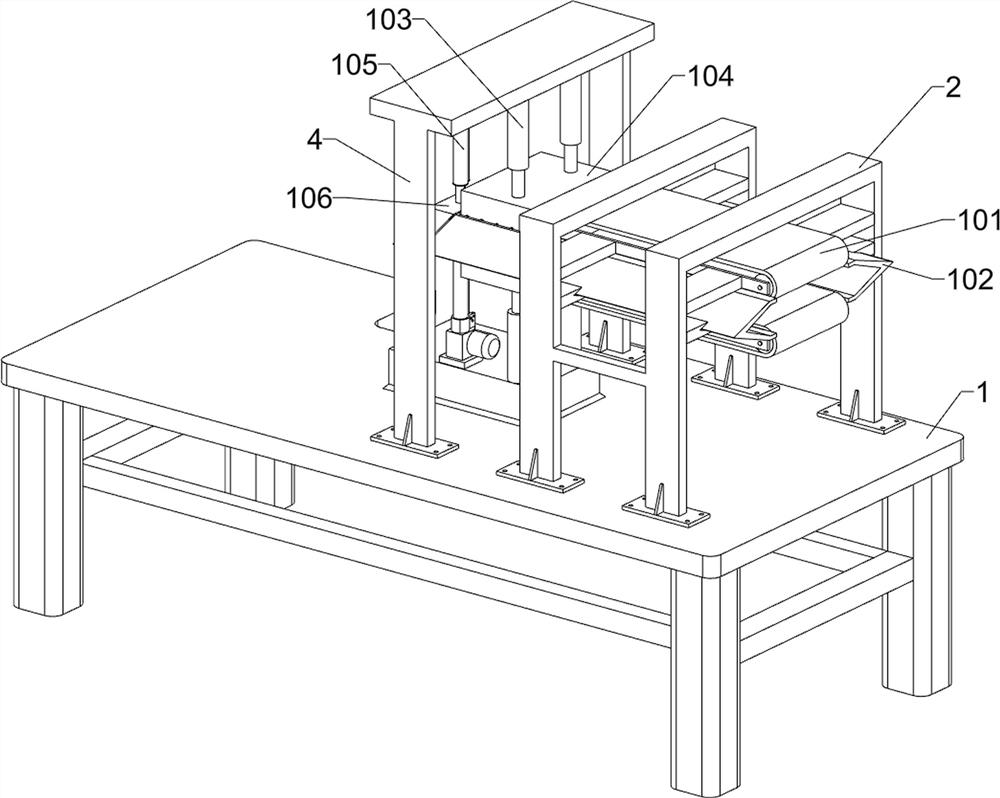

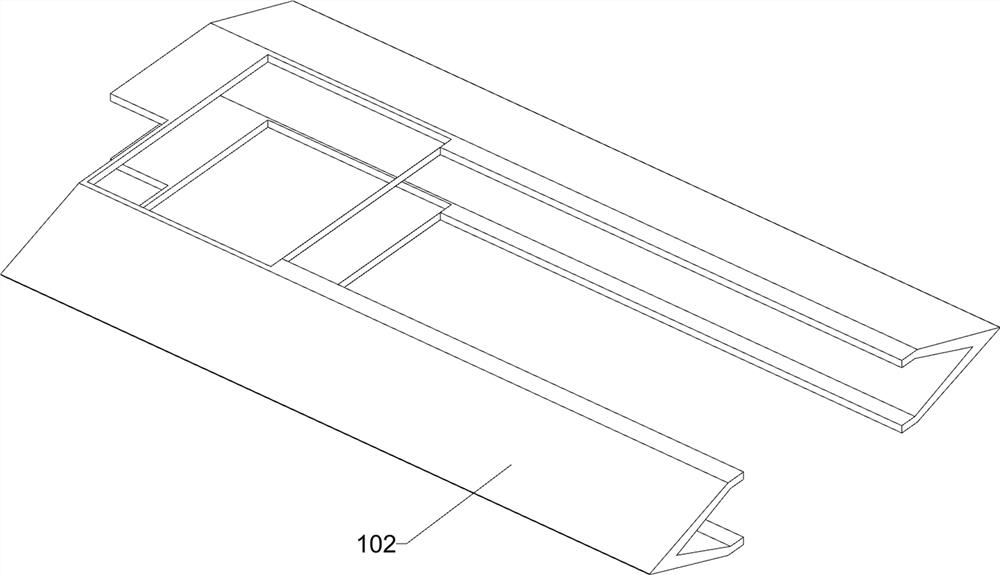

[0032] A food raw fish preprocessing equipment, such as food raw materials Figure 1-11 As shown, including a chassis 1, a mounting frame 2, a first fixing frame 3, a support frame 4, a first collection box 5, a second collection box 6, a conveying assembly, a header, and a visceral scraping assembly; chassis 1 The mounting frame 2 is fixed to the upper right side; the upper side of the bottom frame 1 is fixed to the support frame 4; the top front side of the chassis 1 is connected to the first collection box 5; the mounting frame 2 and the support frame 4 are fixed. There is a first fixing frame 3; the left side of the chassis 1 is provided with a second collection box 6; a conveying assembly is mounted in the mounting frame 2; the conveying assembly is connected to the bottom frame 1 and the support frame 4; the first fixing frame 3 is installed There is a header assembly; the head assembly is connected to the chassis 1; the back part is installed with internal organs.

[0033] T...

Embodiment 2

[0041] On the basis of Example 1, if figure 1 and Figure 12 As shown, there is also a fish belly cleaning assembly, and the fish belly cleaning assembly is attached to the lower side of the fixed disk 202, and the fish belly cleaning assembly includes a second mounting plate 401, a sixth fixing plate 402, a second nozzle 403, a third mounting plate 404. The second small motor 405, the second flat gear 406, the third electric push rod 407, the seventh fixing plate 408, the bracket 409, the bushing 410, the fourth drive rod 411, the second column gear 412, and the ellipsoid 413; The second mounting plate 401 and the sixth fixing plate 402 are fixed to the lower side of the fixed disk 202; the second mounting plate 401 is located on the right of the sixth fixing plate 402; two second fixing plates 402 are fixed to two seconds The nozzle 403; the second mounting plate 404 is fixed to the front side of the second mounting plate 401; the third mounting plate 404 is mounted on the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com