Glass conveying control system

A transmission control, glass technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as breakage, glass collision, cracking, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

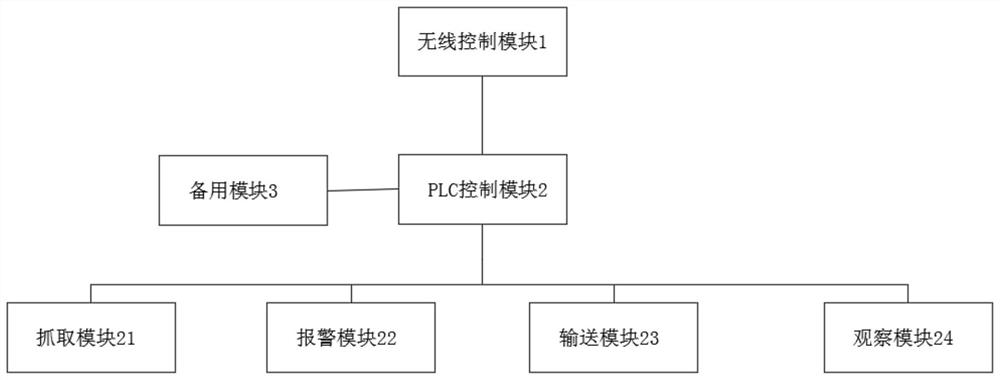

[0033] refer to figure 1 As shown, the present application provides a technical solution: a glass conveying control system, including a wireless control module 1 , a PLC control module 2 and a backup module 3 .

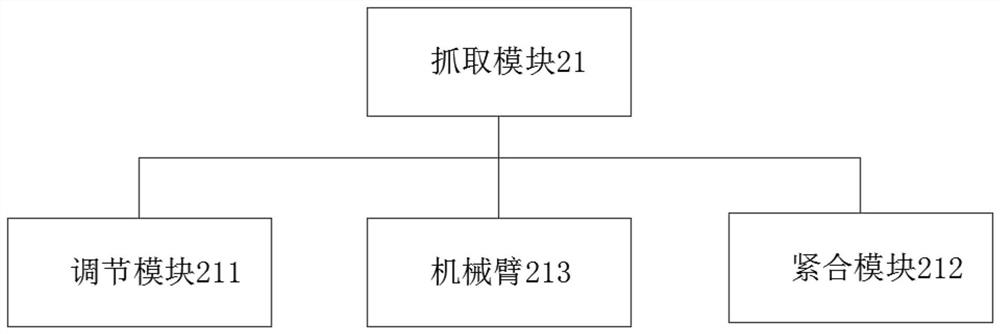

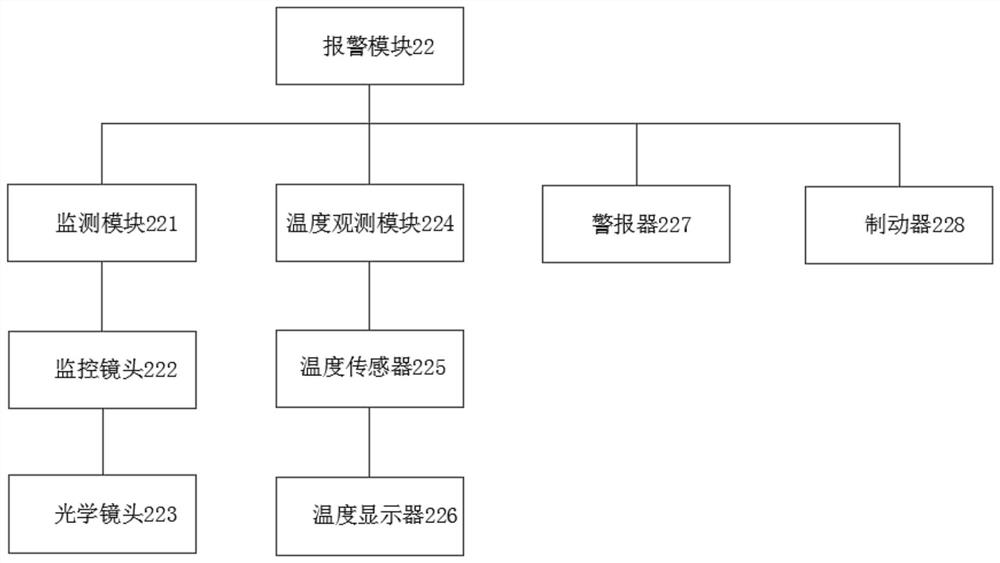

[0034] refer to figure 1 As shown, in this embodiment: the wireless control module 1 is electrically connected to the PLC control module 2, the backup module 3 is electrically connected to the PLC control module 2, and the PLC control module 2 includes a grasping module 21, an alarm module 22, and a delivery module 23 And observation module 24, grabbing module 21, alarm module 22, delivery module 23 and observation module 24 are all electrically connected with PLC control module 2; Glass can be grabbed by grabbing module 21, can be real-time by alarm module 22 Accidents in the conveying process are dealt with, the speed of glass conveying can be adjusted through the conveying module 23, and the situation in the conveying process can be monitored in real time through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com