Novel pulverized coal boiler hydrogen burner and system thereof

A pulverized coal burner and pulverized coal boiler technology, which is applied in the field of power grid system, can solve the problems of waste of resources, decrease of resource utilization rate, large unit load changes, etc., and achieve the effect of improving the combustion effect and the best operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

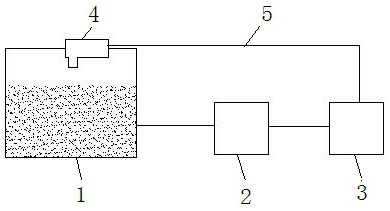

[0022] Based on the problem that the operating load of the power plant is difficult to balance, and the surplus electricity retained after being delivered to the national grid cannot be effectively utilized, the invention provides a method for utilizing surplus electricity in a power plant, which sends the surplus electricity generated by the coal-fired unit of the power plant to an electrolytic hydrogen production device to prepare hydrogen , the hydrogen produced is sent back to the pulverized coal boiler of the coal-fired unit through the pipeline. Among them, electrolytic hydrogen production, hydrogen transmission and coal-fired unit power generation are carried out simultaneously, and hydrogen is transported to the pulverized coal boiler in real time; hydrogen and pulverized coal burners work together to ignite and stabilize combustion, and the sum of the output flow of hydrogen and pulverized coal burners Same as raw outgoing traffic. Its specific structure is as follows...

Embodiment 2

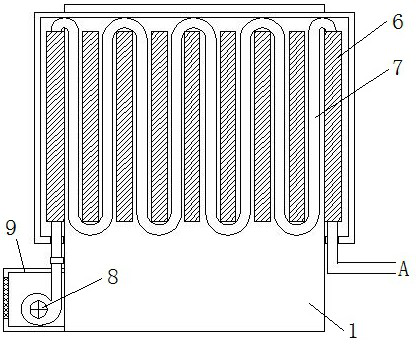

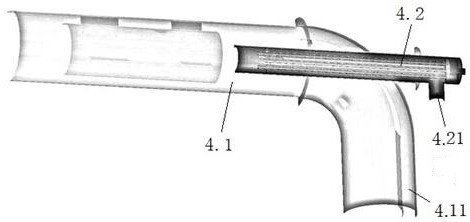

[0041] See attached Figure 1-3 , on the basis of embodiment 1, the air duct of the pulverized coal burner 4.1 is connected to the hot air flow for improving the temperature of the inlet air of the pulverized coal burner; Hot air flow, the heat exchange system of the pulverized coal boiler includes several heat conducting fins 6 arranged on the outer wall of the pulverized coal boiler and the air flow delivery pipes 7 distributed in a serpentine manner between adjacent heat conduction fins, the inlet of the air flow delivery pipes is connected to Blower 8, the outlet of the air delivery pipe 7 communicates with the air duct of the pulverized coal burner 4.1, and the blower 8 is arranged in the air box 9 with a filter screen.

[0042] Based on the above technical solution, the heat of the pulverized coal boiler itself is used to heat the heat conduction sheet, so that the airflow entering the airflow conveying pipe passes through the airflow conveying pipe 7 arranged in a serpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com